Novel horizontal type pile cutting machine

A pile cutting machine, horizontal technology, applied in the field of horizontal pile cutting machine, can solve the problems of noise pollution, dust, low efficiency, etc., to achieve the effect of eliminating noise and dust pollution, fast and efficient crushing, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

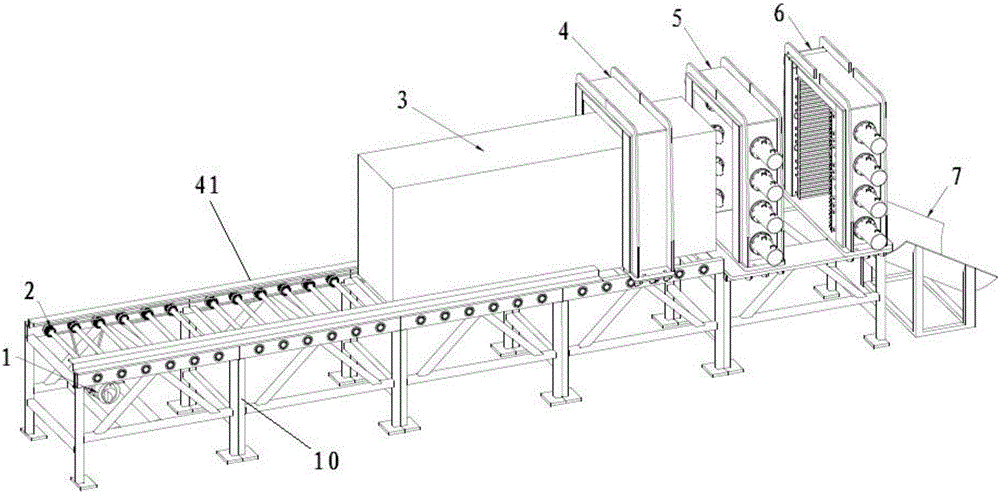

[0010] figure 1 As shown, it relates to a novel horizontal pile cutter, comprising a frame 10, the upper part of the frame 10 is provided with a roller mechanism 2, and the roller mechanism 2 is driven by a sprocket wheel arranged at the bottom of the frame 10 The device 1 is driven to work; the output end of the roll mechanism 2 is sequentially provided with a crushing module 5 and an extrusion module 6 on the frame 10 , and a discharge area 7 is provided at the tail end of the extrusion module 6 . Among them, in order to improve the wear resistance and surface smoothness of the discharge area 7, it is convenient for the discharge of materials. In the present invention, the discharge area 7 includes a low-carbon alloy steel plate, and the low-carbon steel plate is welded with a wear-resistant alloy layer. According to the percentage of the total mass of the wear-resistant alloy layer, the content of each component in the wear-resistant alloy layer is As follows: C: 1.15-1.35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com