Continuous type separation equipment

A technology of separation equipment and transmission part, which is applied in the direction of solid separation, filter screen, grille, etc., which can solve the problems of separation, failure, and easy blockage of continuous working filter net, and achieve the effect of improving breeding efficiency and promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

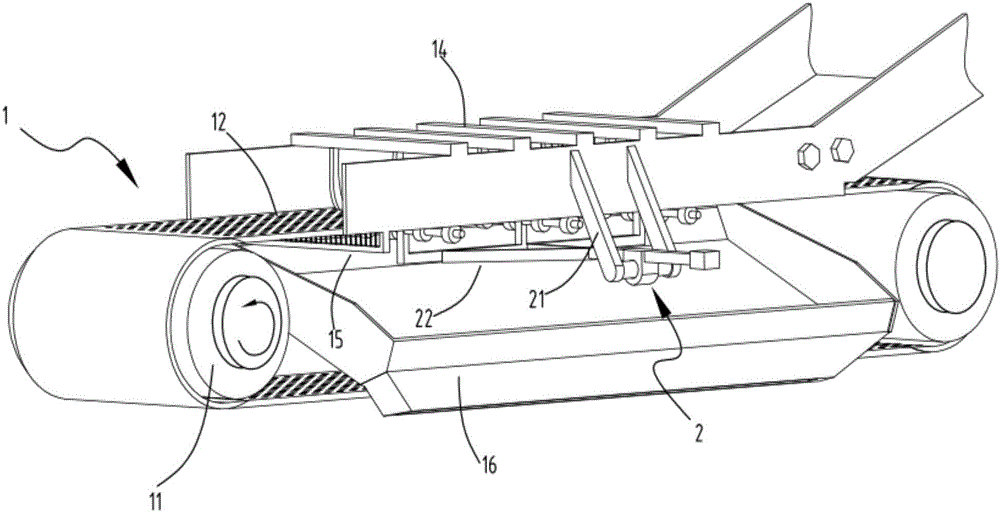

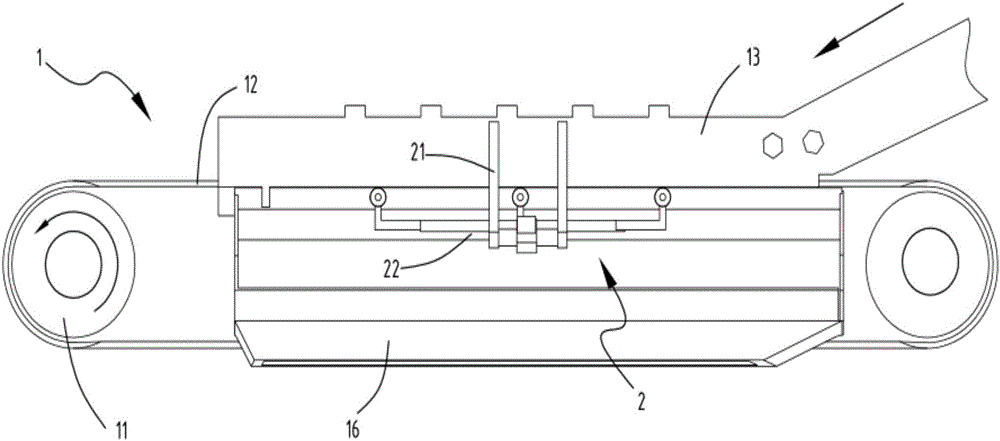

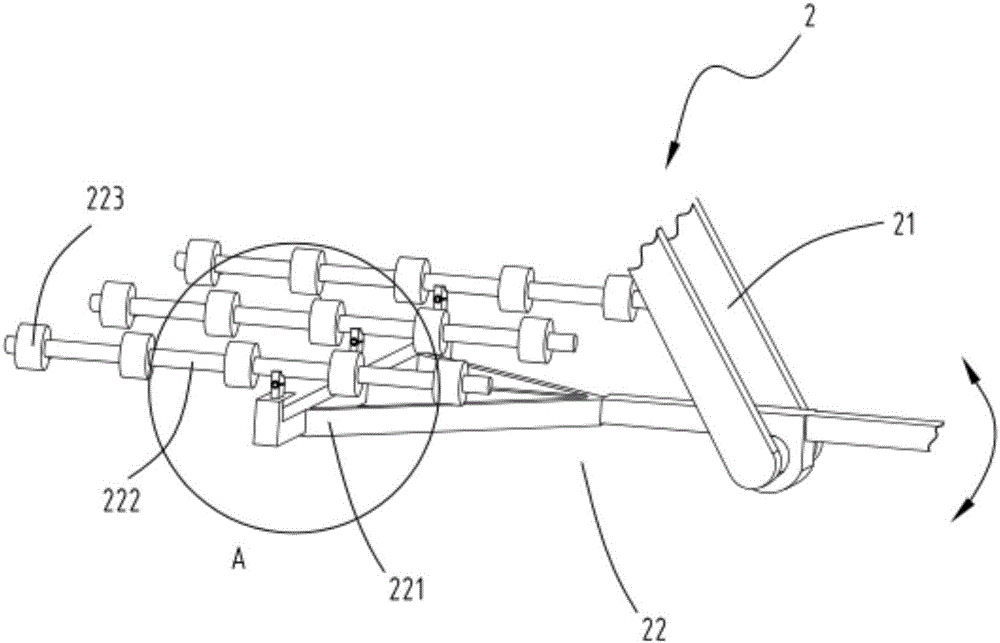

[0032] figure 1 It is a schematic structural diagram of a continuous separation device, figure 2 It is a schematic front view of a continuous separation equipment, image 3 It is a schematic diagram of the structure of the dithering part, Figure 4 It is a partially enlarged schematic diagram of the shaking frame, Figure 5 is a schematic diagram of the structure of the transmission part, Figure 6 It is a partially enlarged schematic diagram of the feeding device, Figure 7 It is a schematic diagram of the structure of the scraping device. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, a kind of continuous separation equipment comprises transmission part 1, and this transmission part 1 comprises power unit 11, and the conveyer belt 12 driven by power unit 11, is provided with blanking hole 121 on described conveyer belt 12; Part 2, the shaking part 2 is arranged under the conveyor belt 12, the shaking part 2 is us...

Embodiment 2

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: further, the bottom of the conveyor belt 12 and the rear end of the shaking frame 221 are provided with a scraping device 15 for removing the material in the blanking hole 121. The device 15 includes a fixed frame 151 and a brush bar 152 arranged on the fixed frame 151 ; the fixed frame 151 is arranged in an L shape, and the brush bar 152 is detachably arranged on the fixed frame 151 .

[0044]The setting of the scraping device 15 enables the powder that may remain in the discharge hole 121 to be promptly removed and dropped into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com