Welding detection device

A welding detection and sliding joint technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of single detection method, large X-ray damage to the human body, and difficult adjustment of detection orientation, so as to improve safety and prevent The effect of radiation leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

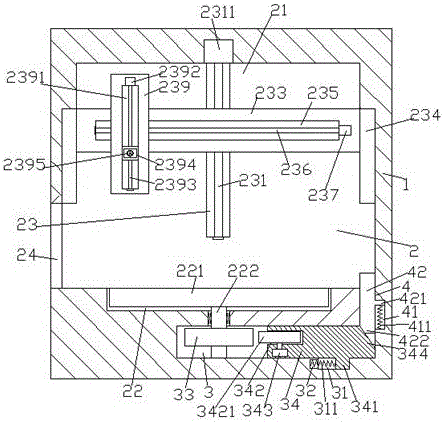

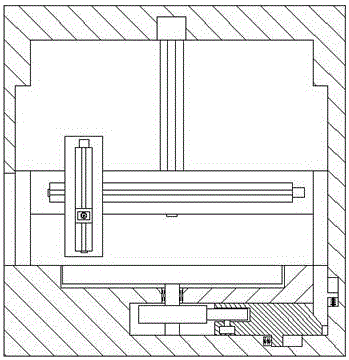

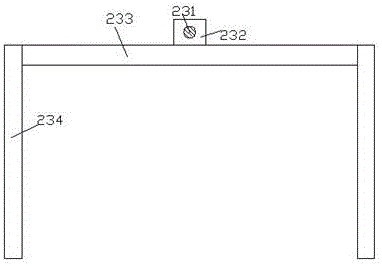

[0020] Such as Figure 1-Figure 5 As shown, a welding detection device of the present invention includes a cabinet 1 with a cavity 2 inside, the top wall of the cavity 2 is provided with a first embedding groove 21, and the bottom wall of the cavity 2 is provided with a There is a second embedding groove 22, and the cabinet body 1 at the bottom of the second embedding groove 22 is provided with a control cavity 3 elongated to the right, and the end of the extension section on the right side of the control cavity 3 is There is a through groove 4 extending upward and penetrating the inner bottom wall of the cabinet body 1, and the rear inner wall of the cavity 2 is provided with a push-up groove extending upward and penetrating into the first embedding groove 21 23. The push-up groove 23 is provided with a first screw-shaped rod 231, and the first screw-shaped rod 231 is connected with the first electric motor 2311, and the first electric motor 2311 is arranged in the first embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com