Numerical control machine tool

A technology of CNC machine tools and power tools, which is applied in the field of CNC machine tools, can solve the problems of damage to workpieces, interrupted cutter heads, and the failure of the motor to lock and stop immediately, and achieve the effects of low cost, improved performance and safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

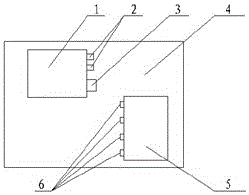

[0015] like figure 1 As shown, the cutting tool at the rear end of the CNC machine tool of the present invention is located on the machine tool body 4, and includes a powered tool 2 and a fixed tool 6. The powered tool 2 is arranged on the sub-spindle base 1, and the fixed tool 6 is arranged on the tool holder 5. The powered tool 2 and the fixed tool 6 are located in different planes; the powered tool 2 and the sub-spindle 3 are located in the same horizontal plane, there are 2 powered tools 2 and 4 fixed tools 6 . The fixed tool 6 and the sub-spindle 3 cooperate with each other to process materials or parts to be processed, and the power tool 2 is on the sub-spindle base 1 and uses common power with the sub-spindle 3 to process materials or parts to be processed on the opposite main shaft. It enriches the processing methods of CNC machine tools.

[0016] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com