Grinding equipment with automatic discharge function

An automatic unloading and functional technology, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of prolonging the wafer grinding processing time, reducing the wafer processing efficiency, increasing the workload of workers, etc., to ensure the grinding effect, The effect of improving processing efficiency and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific implementations:

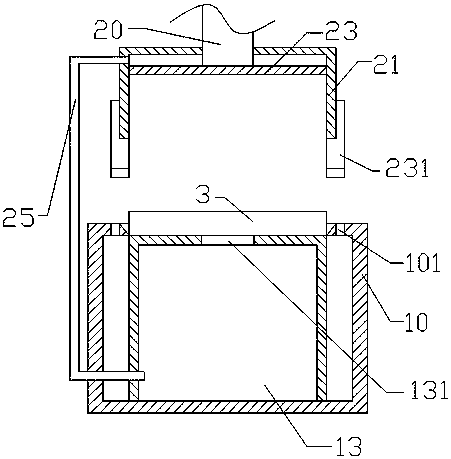

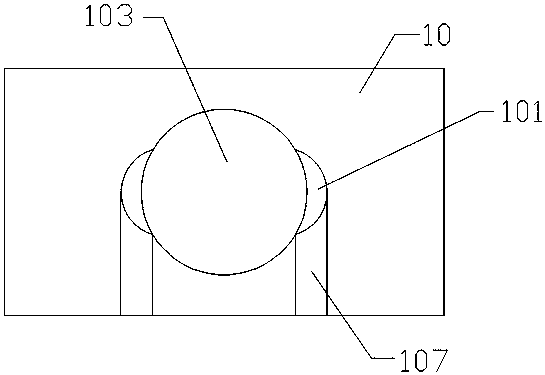

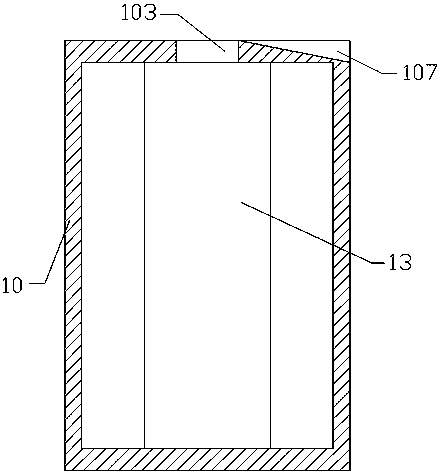

[0021] The reference signs in the drawings of the specification include: processing table 10, placement table 13, suction hole 131, slot 101, placement hole 103, wafer 3, clamping rod 231, connecting rod 235, driving box 21, polishing head 23, The drive rod 20, the air duct 25, and the guide groove 107.

[0022] Such as figure 1 with figure 2 The shown grinding equipment with automatic unloading function includes a processing table 10 for placing a wafer 3 to be ground and a grinding mechanism for grinding the wafer 3. The grinding mechanism is located above the processing table 10, and the grinding mechanism includes a grinding head 23, The driving rod 20 and the driving box 21 that is sleeved on the driving rod 20 and the opening faces downward, the grinding head 23 is slidingly fitted in the driving box 21, the lower end of the driving rod 20 extends into the driving box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com