Variable stiffness conical helical spring array polishing plate

A coil spring and polishing disc technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problem that free-form surfaces are difficult to polish and process, and achieve good adaptability, compact structure, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

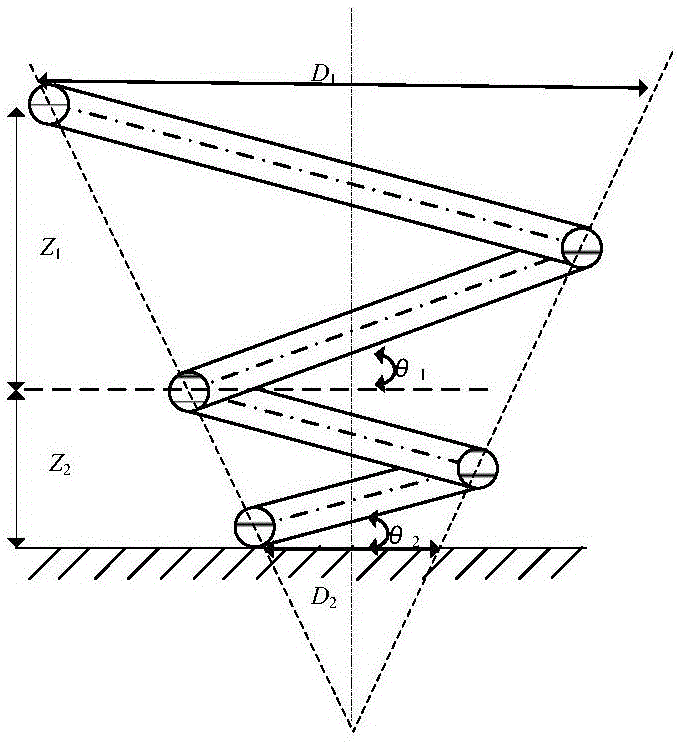

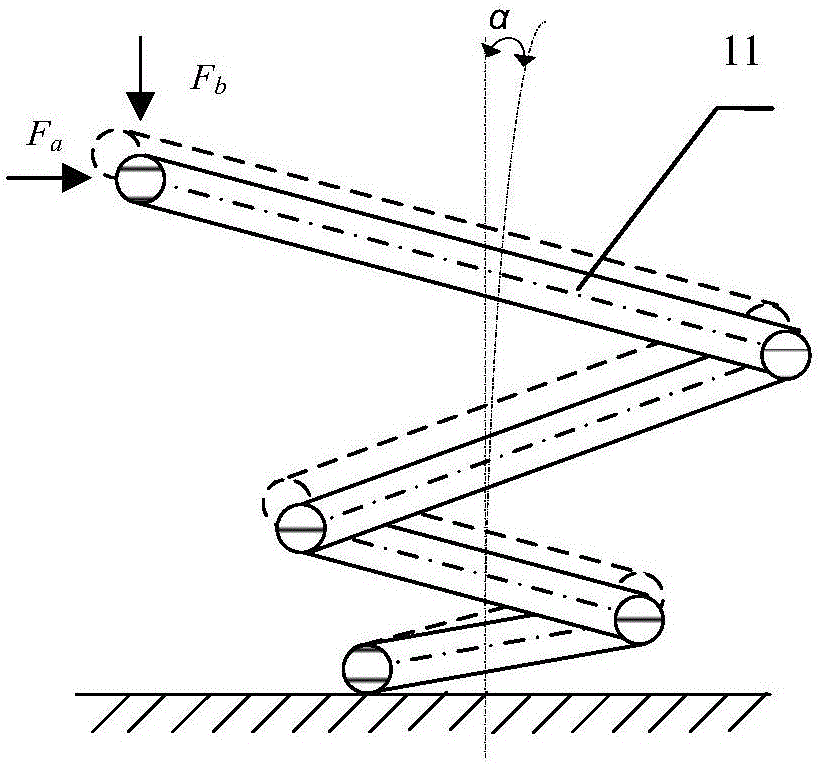

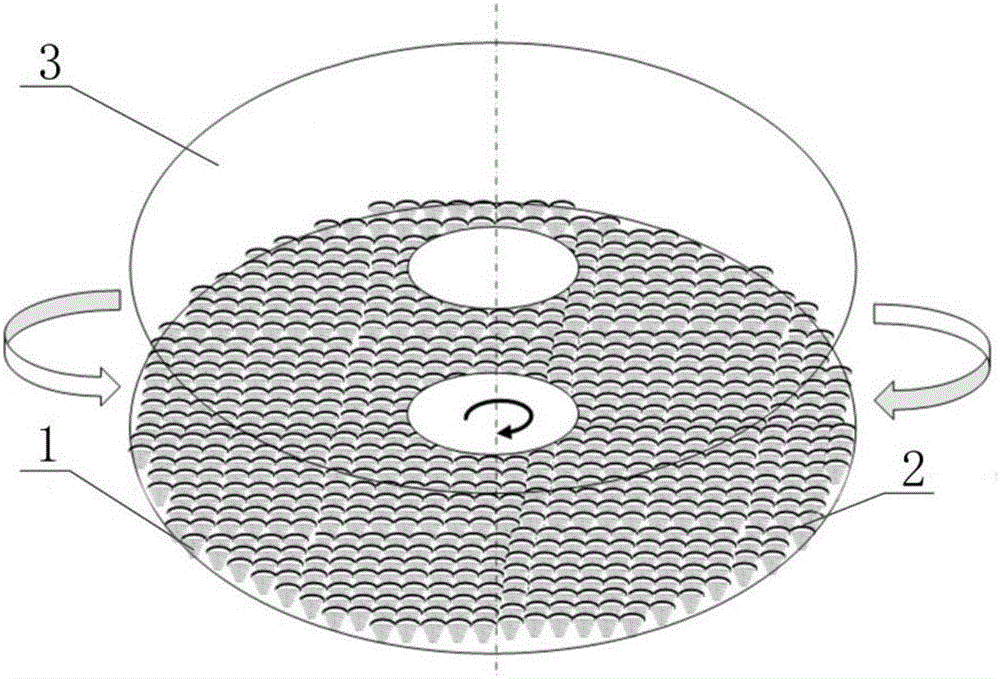

[0020] Embodiment 1 The variable stiffness conical coil spring array polishing disc of the present invention includes a polishing disc body 4, a conical coil spring array 1, a polishing pad 3 and a hemispherical support 2, and the upper part of the polishing disc body 4 is provided with Polishing chamber, the bottom of the polishing disc body 4 is fixedly connected with the rotary table driven by the motor, so as to realize the circumferential rotation of the polishing disc body 4 around its central axis; the inner bottom surface of the polishing disc body 4 is equipped with a conical spiral Spring array 1; the upper surface of the conical helical spring array 1 is covered with a polishing pad 3 for supporting abrasive grains and waterproof protection; the conical helical spring array 1 includes several mutually independent conical helical springs 11, each A conical coil spring 11 corresponds to a hemispherical support 2, and the small-diameter end of the conical coil spring 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com