Precision reducer

A precision reducer and intermediate meshing technology, applied in the mechanical field, can solve the problems of material fatigue, large volume, expensive price, etc., and achieve the effect of meeting volume requirements, small volume, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

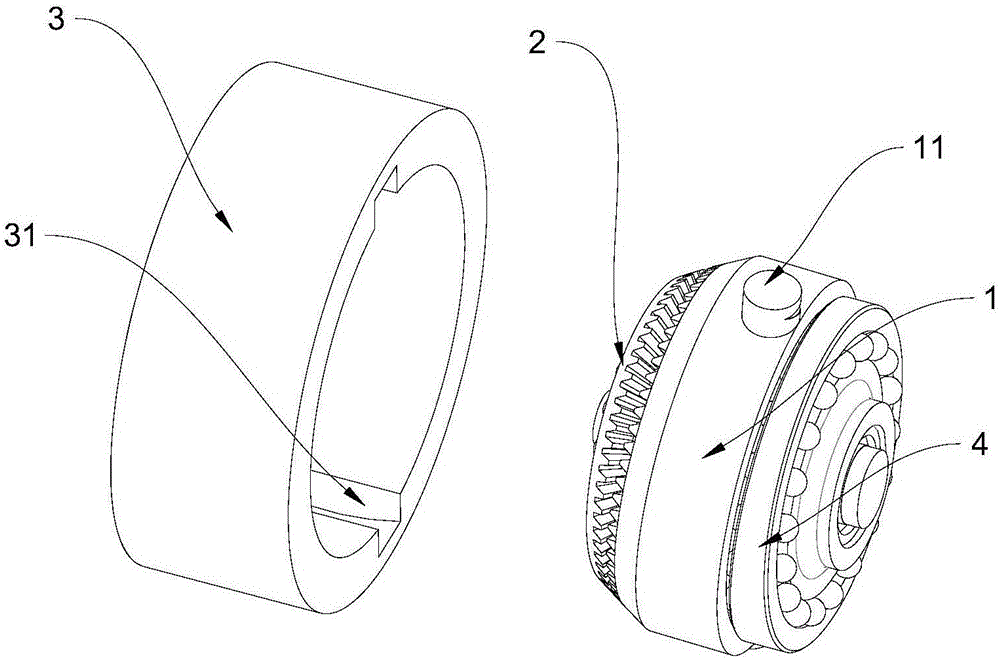

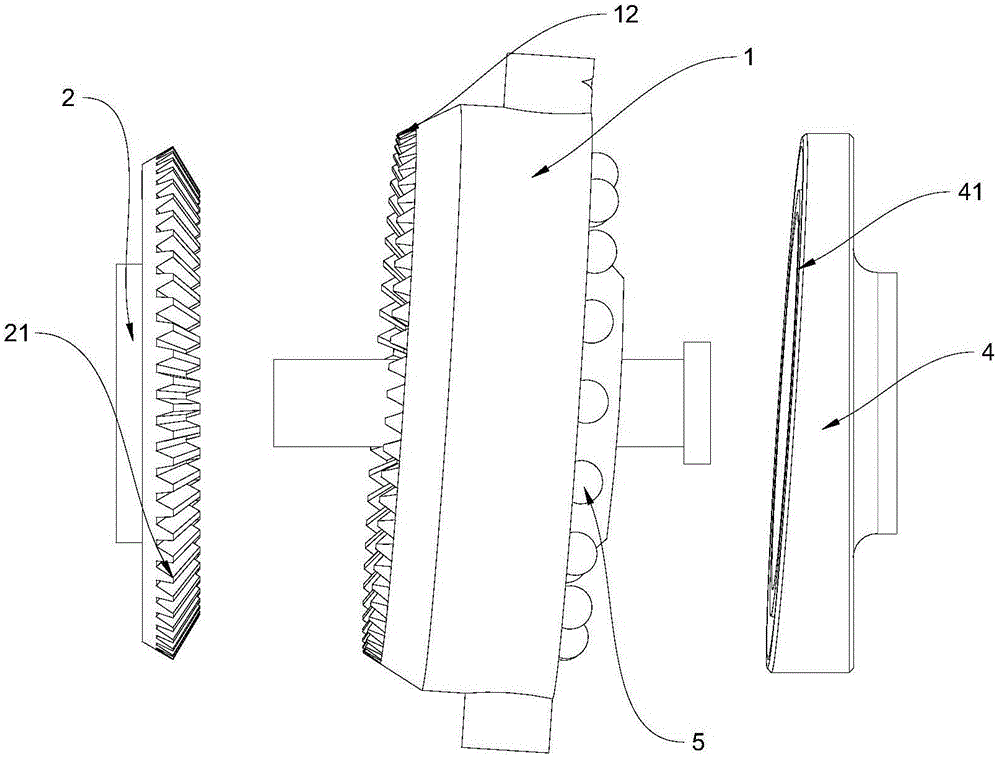

[0029] see Figure 1-Figure 3 , the present invention provides a precision reducer, including a middle meshing disk 1 and an output disk 2, the middle meshing disk 1 meshes with the output disk 2, and the specific meshing method is: the top surface of the middle meshing disk 1 is provided with several The first teeth 12 evenly distributed on the axis 7 of the meshing disc, the second teeth 21 evenly distributed around the axis of the output disc 2 are provided on the bottom surface of the output disc 2, and the meshing between the middle meshing disc 1 and the output disc 2 is the first tooth 12 For meshing with the second teeth 21 , it should be emphasized that there is a difference between the number of teeth of the first teeth 12 and the number of teeth of the second teeth 21 .

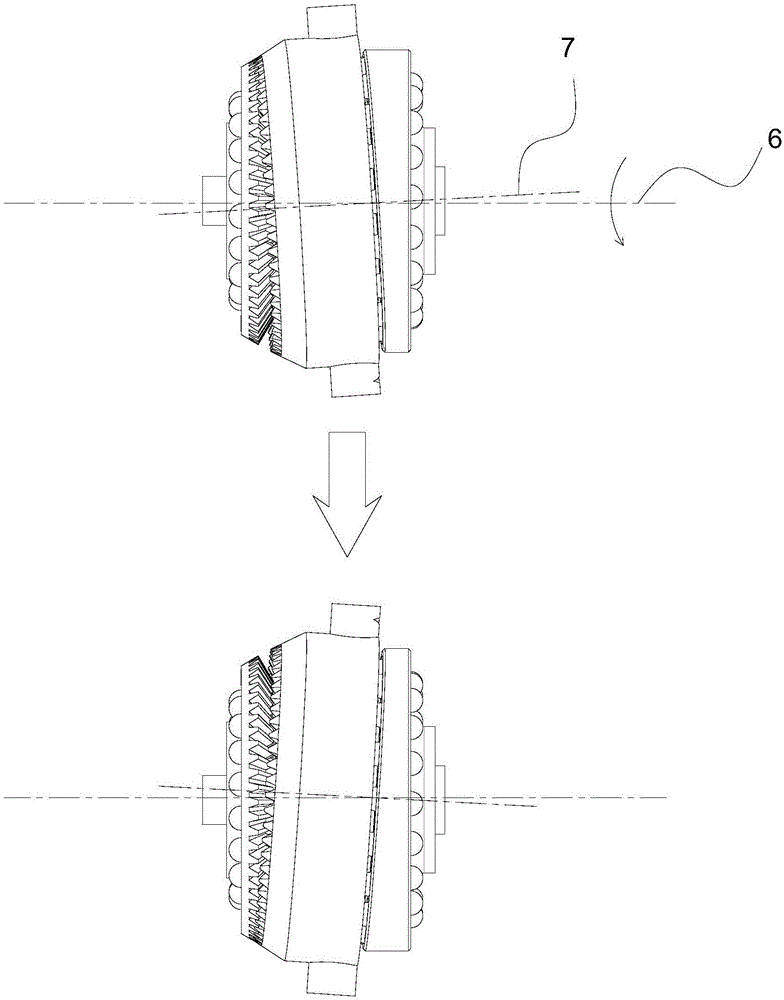

[0030] The axis 7 of the middle meshing disk intersects the axis of the output disk 2 at one point, that is to say, there is a certain angle between the axis 7 of the middle meshing disk and the ax...

Embodiment 2

[0043] On the basis of Embodiment 1, Embodiment 2 adds a rotating disk 4, and a mounting slope 41 is provided on one side of the rotating disk 4. The angle interval between the rotation axis 6 of the rotating disk 4 and the mounting slope 41 is [2 °, 90 °), the specific example of the included angle is 10 °, 30 °, 45 °, 60 °, 75 °, 80 °, 85 °, the bottom surface of the middle meshing disc 1 is installed on the installation slope 41 of the rotating disc 4 Above, the rotation axis 6 of the rotating disk 4 is on the same straight line as the axis of the output disk 2, and the axis 7 of the intermediate meshing disk intersects the rotation axis 6 of the rotating disk 4 at a point, and this point is located on the installation slope 41, and the installation slope 41 is provided with a circle of balls 5, and the bottom surface of the middle meshing disc 1 is installed on the installation slope 41 through the balls 5.

[0044] Specifically, the rotating disk 4 rotates around the axis...

Embodiment 3

[0048] On the basis of the second embodiment, the ring of balls 5 in the second embodiment is replaced with a bearing, also to ensure that the rotation of the rotating disk 4 does not drive the rotation of the intermediate meshing disk 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com