Water heating constant-temperature cutting device of illumination optical fiber

A cutting device, optical fiber water technology, applied in metal processing and other directions, can solve the problems of labor-consuming and time-consuming processing cost, heat conduction, heat preservation, temperature control and poor cutting effect, etc., to save cutting time, improve processing effect and cutting effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with accompanying drawing:

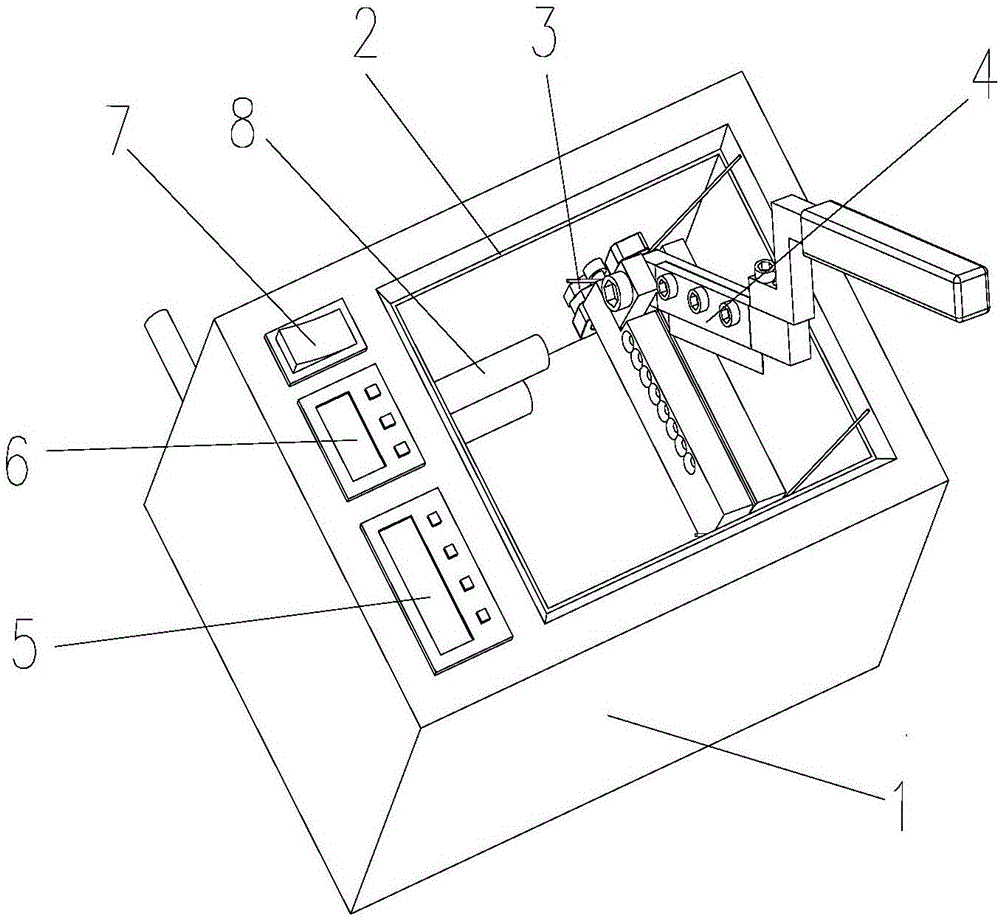

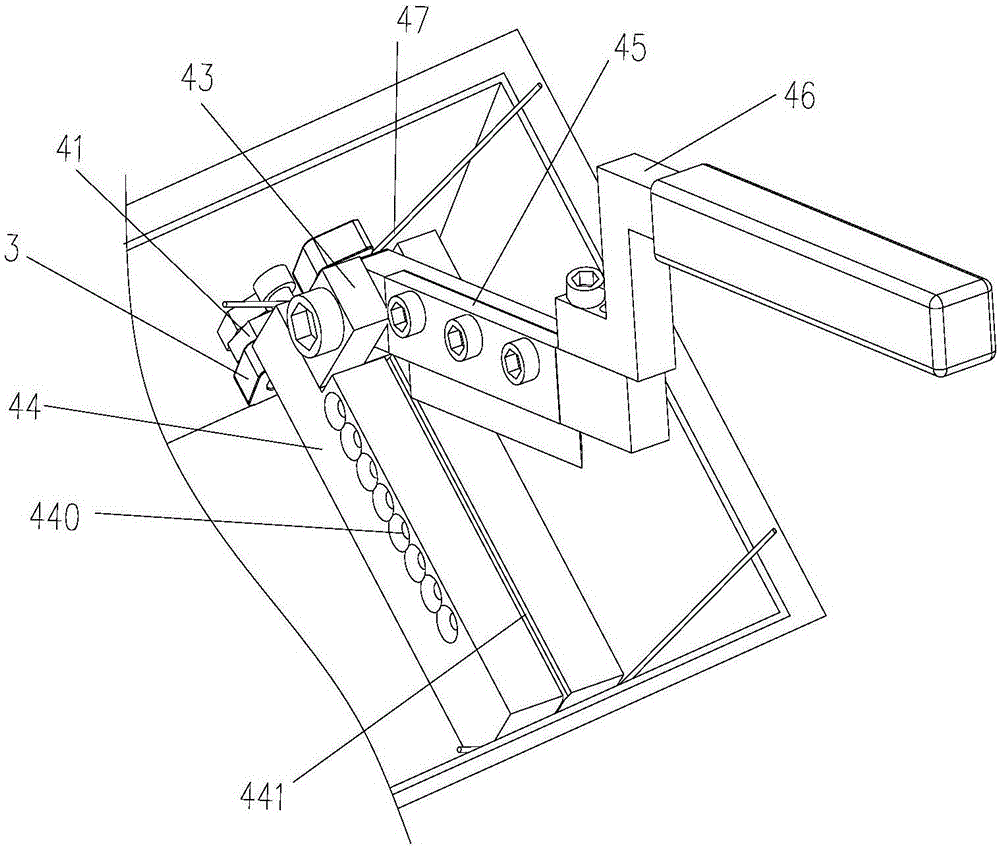

[0026] as attached Figure 1-4 The illustrated optical fiber water heating constant temperature cutting device includes a rectangular housing 1, a rectangular open water tank 2 is arranged in the rectangular housing 1, and a guillotine-type optical fiber cutting mechanism 4 is installed in the rectangular open water tank 2.

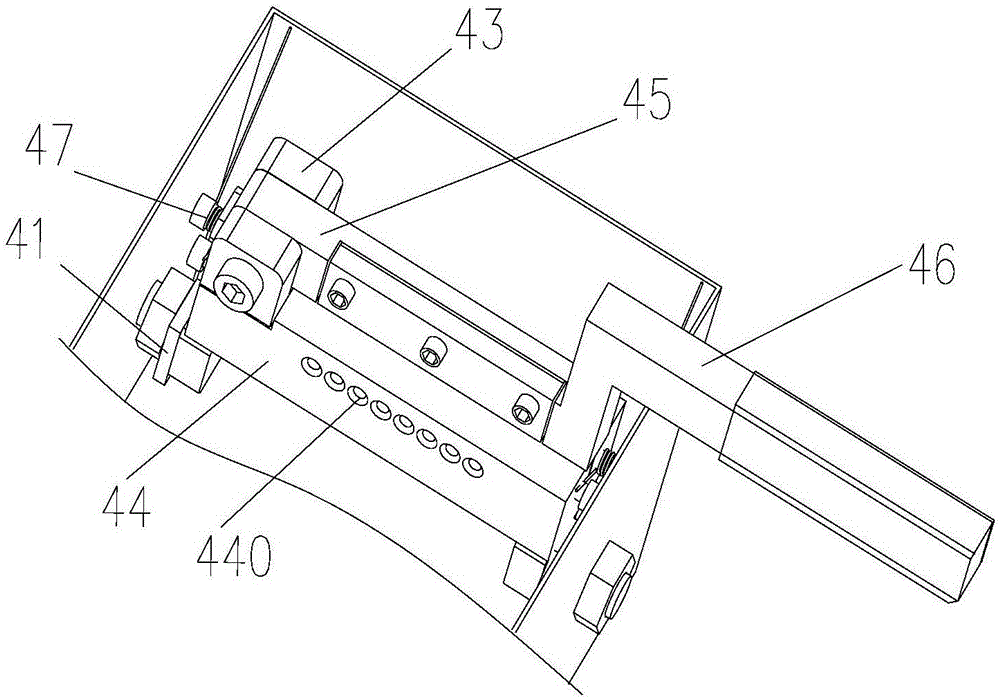

[0027] From attached figure 2 , attached image 3 , attached Figure 4 combined with figure 1 It can be seen that the guillotine-type optical fiber cutting mechanism 4 includes a front support plate 41, a rear support plate 42, a mounting seat 43, a strip cutting block 44 and a cutting knife body 45, and the vertical cutting block 44 is The center is provided with a cutting slit 441, and a number of cutting through holes 440 are arranged at lateral intervals on the side of the elongated cutting block 44, and the position of the cutting through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com