Belt film heat-seal forming equipment

A thermal synthesis and equipment technology, applied in the direction of flat products, household utensils, and other household utensils, can solve the problems of film stretching, damage to the flatness and tightness of the film, and the difficulty of roller shaft processing, so as to ensure flatness and The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

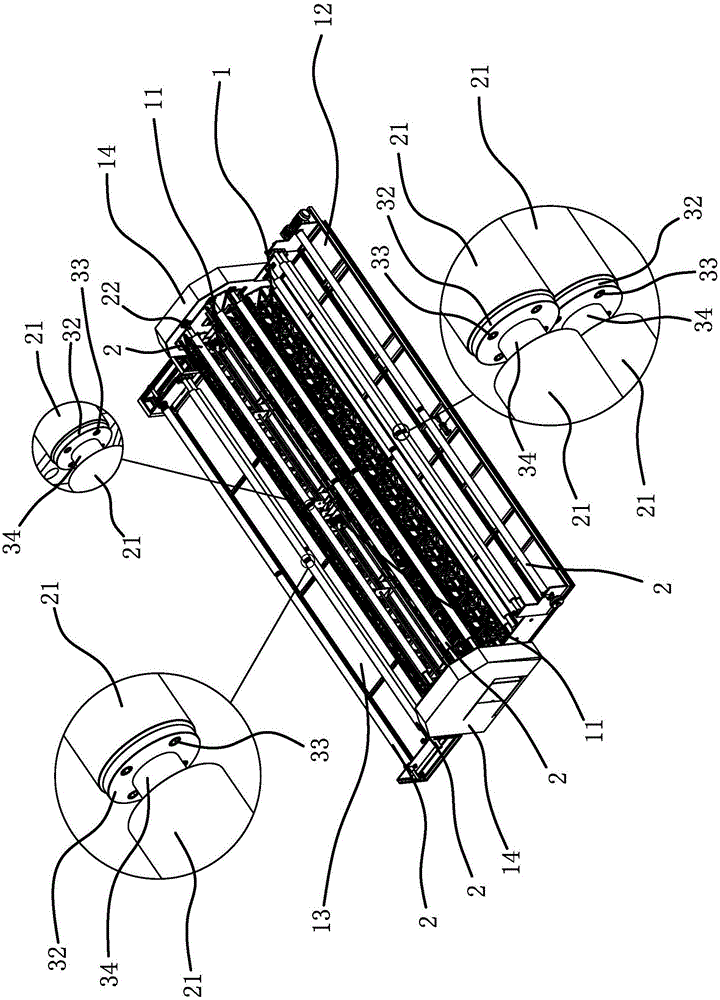

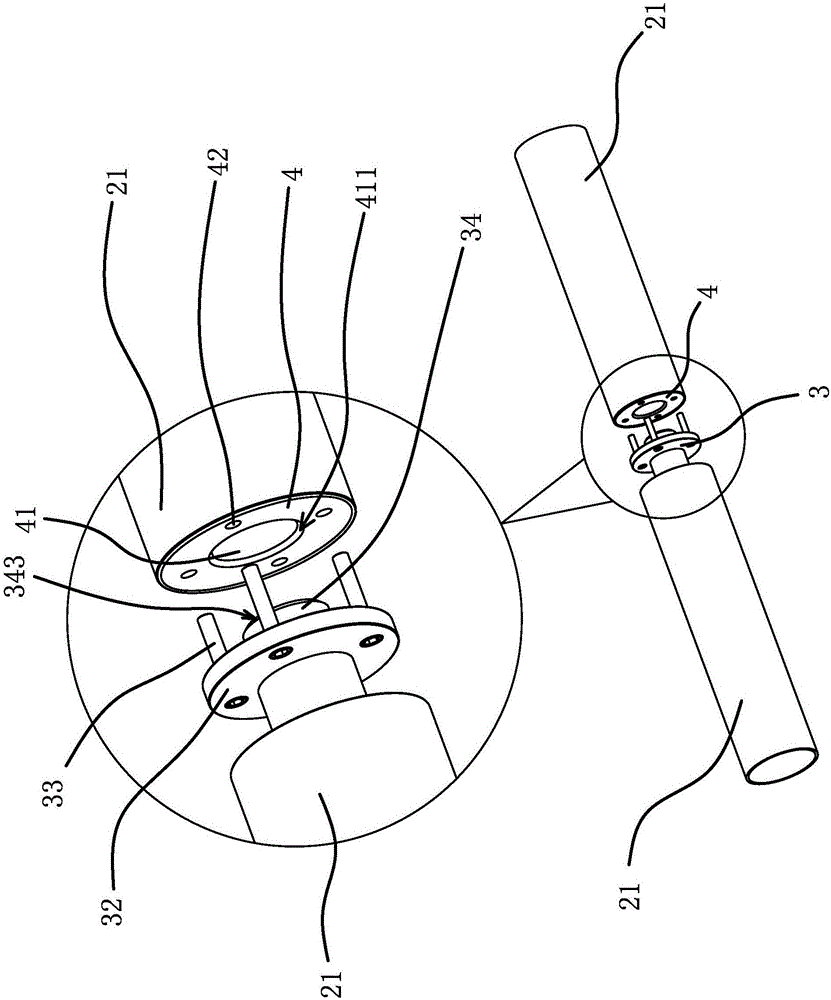

[0027] Such as figure 1 and figure 2 As shown, the heat-synthesizing equipment with film includes a frame 1, a heat-sealing mechanism 11 arranged in the frame 1, and an input mechanism 12 and an output mechanism 13 are respectively arranged on both sides of the frame 1. On the frame 1 and the input mechanism 12 Both the drive roller shaft 2 and the output mechanism 13 are provided with the drive roller shaft 2. The drive roller shaft 2 is supported by the frame seats 14 located at both ends. The drive roller shaft 2 is composed of two axially penetrating hollow shafts 21. One end is plugged and fixed with a solid connecting shaft 22, and the connecting shaft 22 is connected with the corresponding frame base 14, and the other end of one hollow shaft 21 is plugged and fixed with a splice 3, and the other end of the other hollow shaft 21 One end is plugged and fixed with splicing piece 2 4, and splicing piece 1 3 can be plugged and fixed with splicing piece 2 4 so that the two ...

Embodiment 2

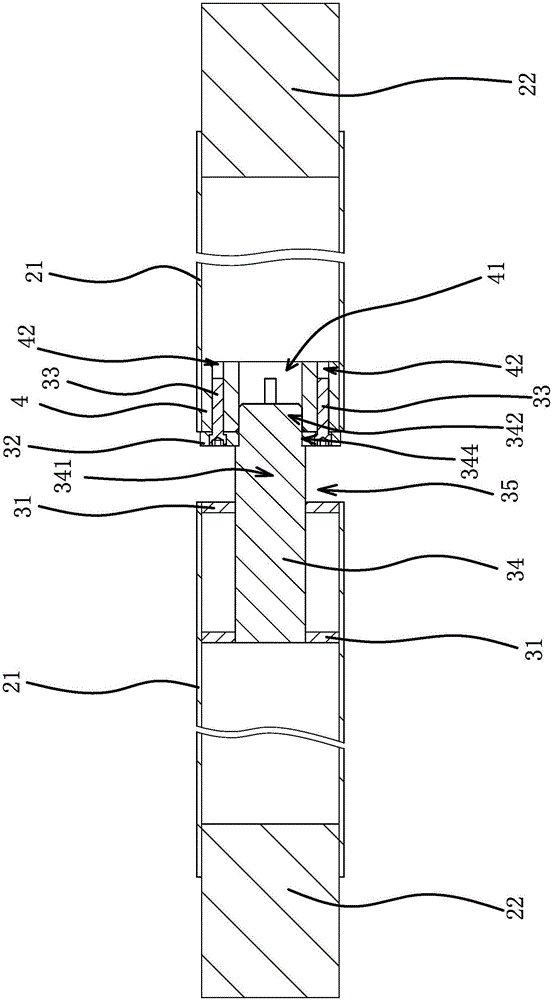

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 4 As shown, the transmission roller shaft 2 is supported by the frame bases 14 located at both ends and the middle part of the transmission roller shaft 2 is supported by a support ring 51. The specific structure is as follows: a bearing 5 is sleeved on the relief section 341, and the width of the bearing 5 is smaller than the gap The width of 35, the inner ring of bearing 5 is fixed with step-off section 341, and the outer ring of bearing 5 is covered with support ring 51, and the diameter of support ring 51 is less than the diameter of hollow shaft 21. The supporting ring 51 can be connected with the frame 1, the supporting ring 51 is fixed relative to the frame 1, the driving roller shaft 2 rotates relative to the supporting ring 51, the outer peripheral surface of the supporting ring 51 does not protrude from the outer peripheral surface of t...

Embodiment 3

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: figure 1 As shown, the transmission roller shaft 2 is only supported by the frame bases 14 located at both ends, the transmission roller shaft 2 is composed of two axially penetrating hollow shafts 21, and one end of the two hollow shafts 21 is plugged and fixed with a solid Connecting shaft 22, the connecting shaft 22 is connected with the corresponding frame seat 14, the other end of one hollow shaft 21 is plugged and fixed with splicing piece 1 3, and the other end of the other hollow shaft 21 is plugged and fixed with splicing piece 2 4 , splicing piece 1 3 can be plugged and fixed with splicing piece 2 4 so that the two hollow shafts 21 are positioned both in the circumferential direction and in the axial direction, and neither splicing piece 1 3 nor splicing piece 2 4 protrudes from the outer peripheral surface of the corresponding hollow shaft 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com