Adhesive applying device for honeycomb paperboards

A technology of gluing device and honeycomb paperboard, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problem of edge damage of honeycomb paperboard, achieve the effect of smooth pasting and avoid edge damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

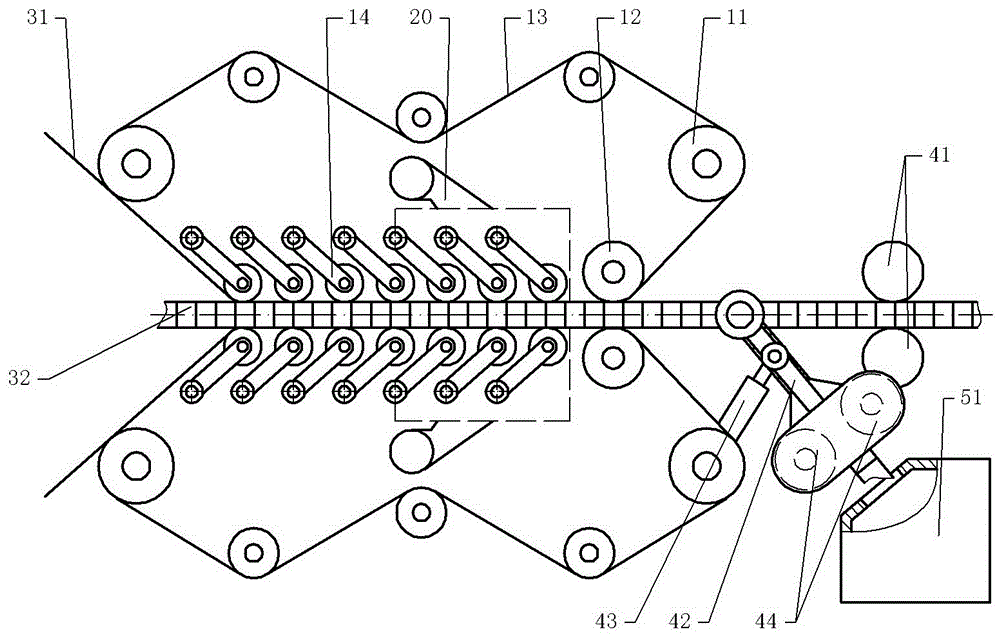

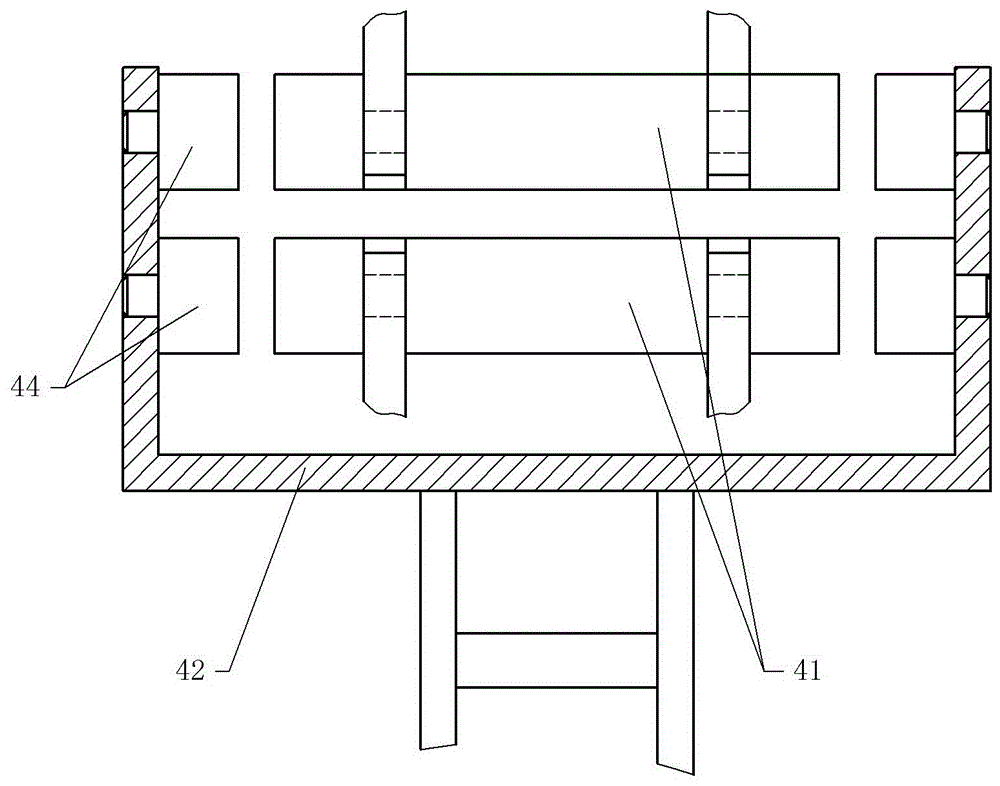

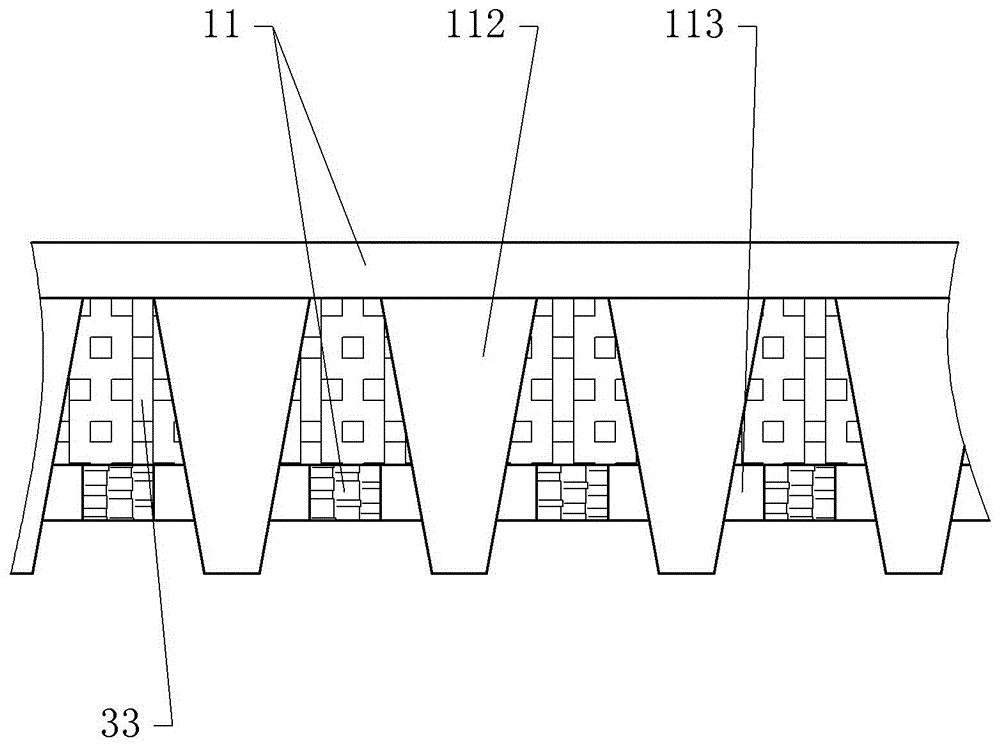

[0024] The reference signs in the drawings of the description include: tension roller 11, drive roller 12, endless pressure belt 13, flattening roller group 14, cutting nails 112, nail holes 113, oven 20, face paper 31, paper core 32, honeycomb Cardboard 33, supporting roller group 41, support 42, air cylinder 43, separation roller group 44, paper shredder 51.

[0025] The embodiment is basically as figure 1 , figure 2 , image 3 Shown:

[0026] The honeycomb paperboard gluing device of the present embodiment comprises a frame, an oven 20, and two groups of drive units arranged symmetrically up and down and installed on the frame. The drive unit includes an endless pressure belt 13, a tension roller 11, a drive roller 12 and Flattening roller group 14, tensioning roller 11 tensions ring-shaped pressure belt 13, driving roller 12 drives ring-shaped pressure belt 13 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com