Flexible charging optimization method sufficiently using electric vehicle off-board charger

An electric vehicle and optimization method technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of increased logic complexity and high cost of power distribution gear output bus software, and achieve cost savings and high compatibility. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

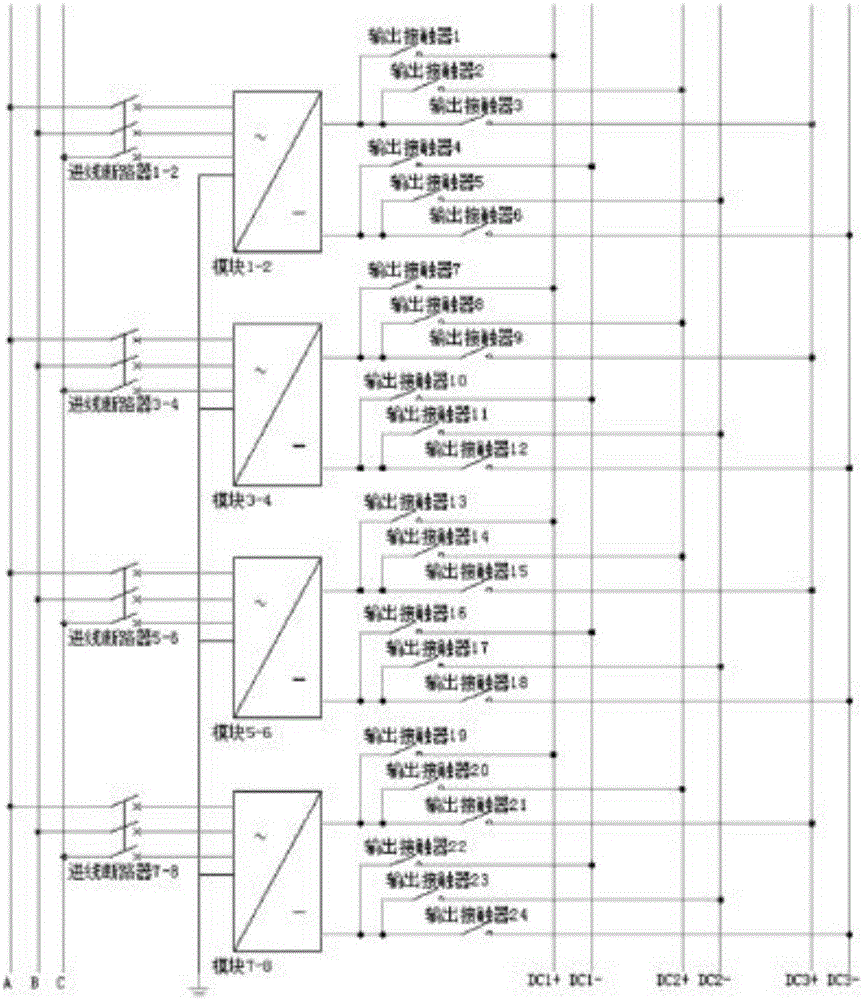

[0029] A flexible charging optimization method that fully applies the off-board charger of electric vehicles (see attached figure 2 To attach Figure 5 ), including the following steps:

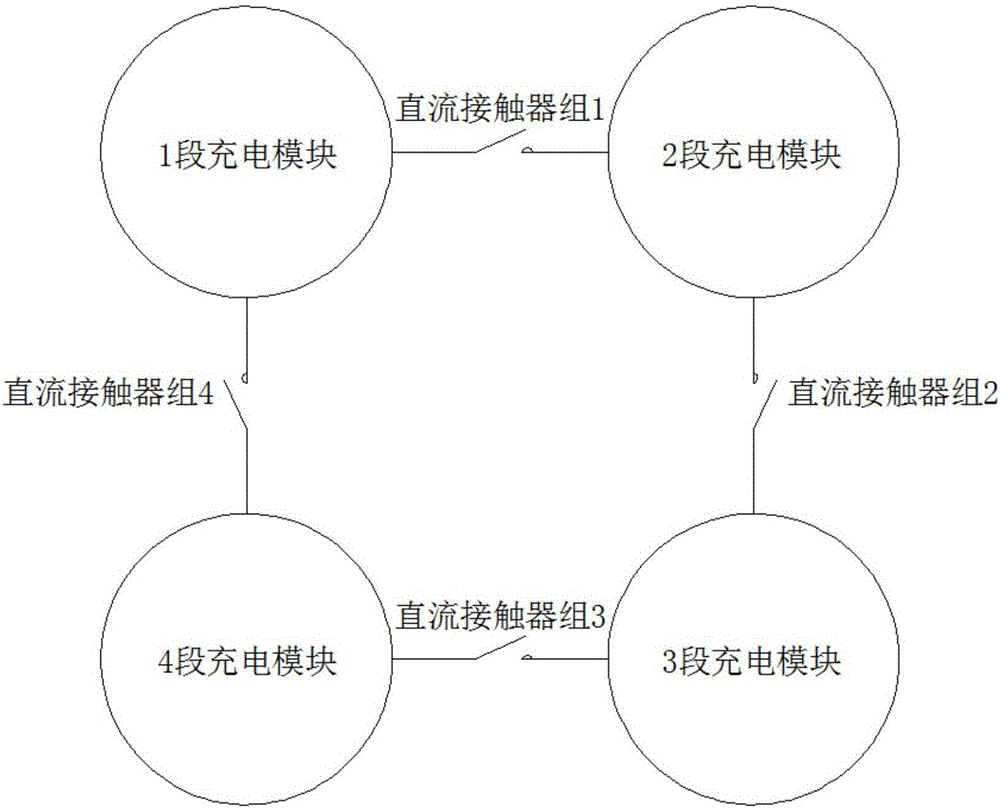

[0030] Step 1: Establish a ring network form to connect the AC-DC conversion modules as required. Control switches are arranged between the AC-DC conversion modules, and each AC-DC conversion module corresponds to a charging interface and a demand data reader. The control terminal of the control switch is connected to the main charging controller, and the demand data reader is also connected to the main charging controller; the first AC-DC conversion module and the last AC-DC conversion module are equipped with control switch.

[0031] Control switches are arranged between the adjacent AC-DC conversion modules.

[0032] Step 2: The main charging controller judges the working status and working quantity of the current AC-DC conversion module according to the working status of the charging ...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is:

[0040] In the first step, each charging interface is equipped with a control switch for locking, the control end of the control switch for locking is connected to the main charging controller, and the control switch for locking is normally closed.

[0041] In said step 4, the control switch for locking corresponding to the idle AC-DC conversion module in the working state is turned off, and the charging interface corresponding to the control switch for locking stops charging until step 7, leading to the working state The control switch for locking corresponding to the idle AC-DC conversion module is closed and turned on again. Example 3:

Embodiment 3

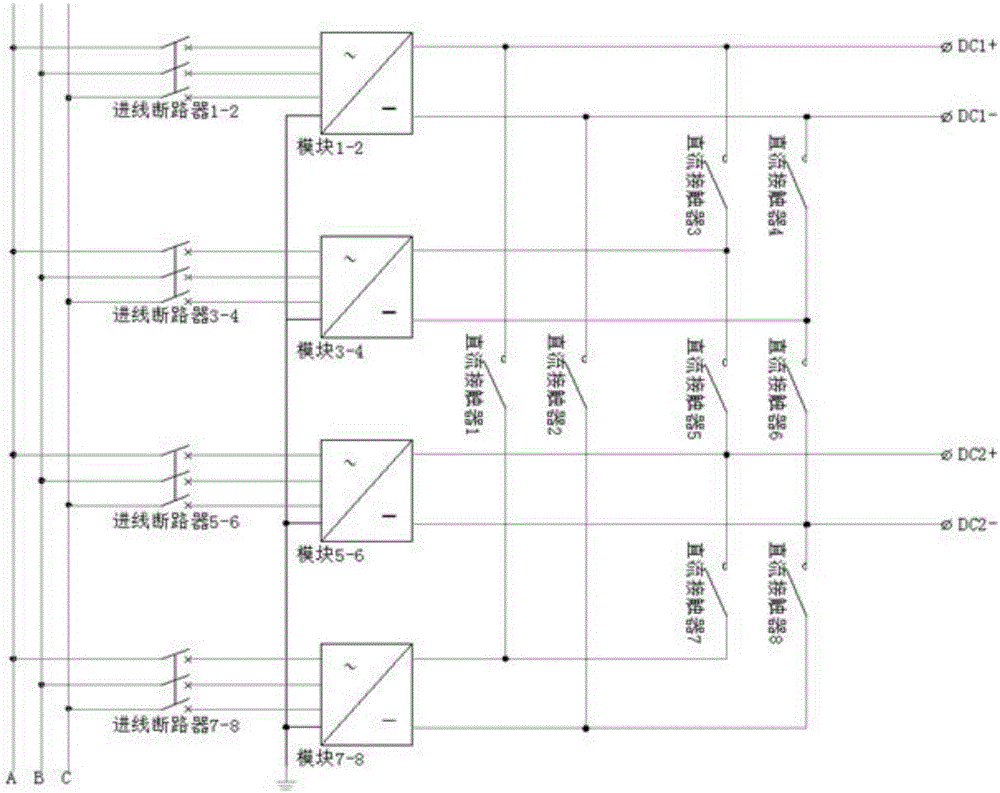

[0042] This embodiment is basically the same as Embodiment 1, the difference is:

[0043] A control switch is arranged between any of the AC-DC conversion modules (see attached Figure 6 And attached Figure 7 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com