Automatic box packing device of capsule production line

An automatic boxing and production line technology, applied in packaging and other directions, can solve the problems of increasing the labor force of workers, reducing production efficiency, and difficulty in ensuring accuracy, so as to achieve the effect of improving boxing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

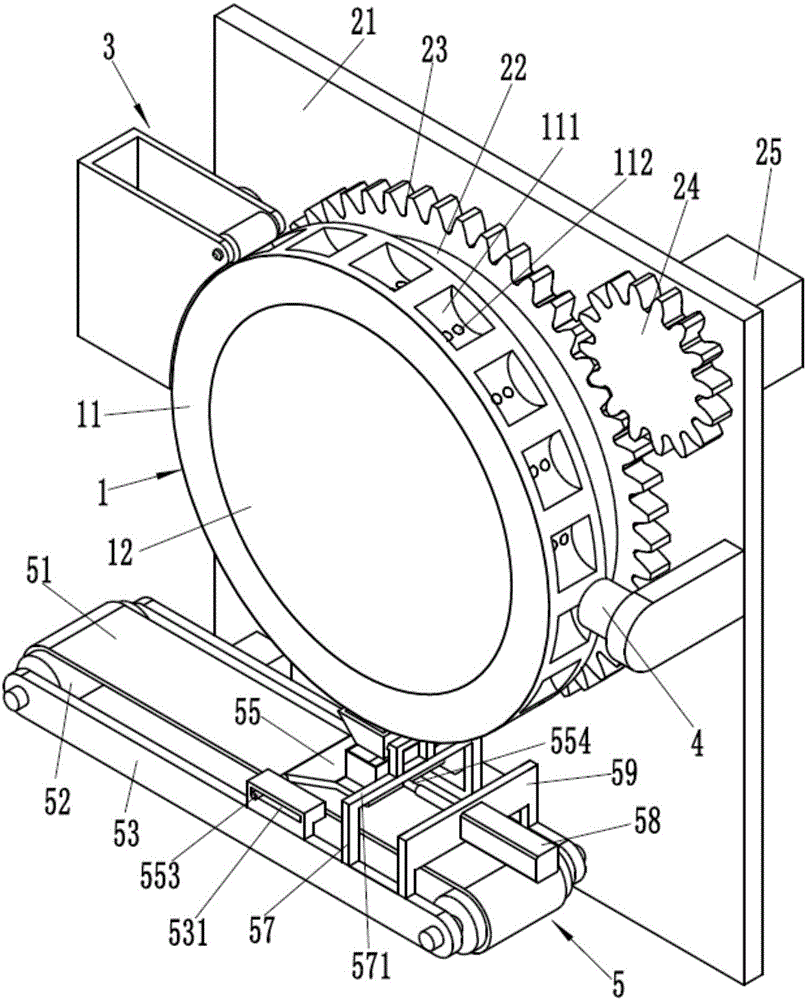

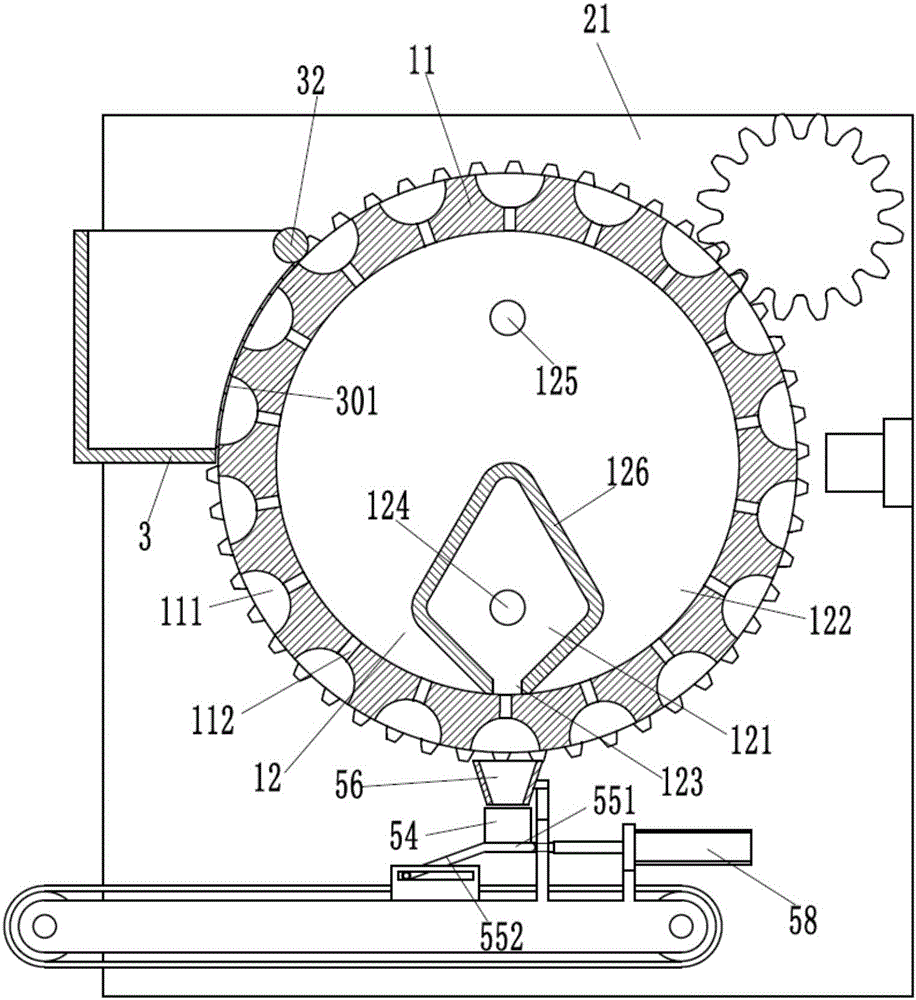

[0019] Examples, see e.g. Figure 1 to Figure 2 As shown, an automatic boxing device for a capsule production line includes a rotary discharge mechanism 1, the rotary discharge mechanism 1 includes a hollow turntable 11, and a plurality of storage grooves 111 are evenly formed on the outer wall of the turntable 11. The storage grooves 111 A number of small holes 112 are formed on the top, and the inside of the turntable 11 is sleeved with a blowing suction cup 12. The small holes 112 communicate with the inner cavity of the blowing suction cup 12, and the blowing suction cup 12 is fixed on the base plate 21; A feeding box 3 is provided on the side, a quantity monitoring camera 4 is provided on the right side of the turntable 11, a discharge mechanism 5 is arranged below the turntable 11, and a circle arranged with the center of the turntable is fixedly connected to the rear side of the turntable 11. Ring 22, the circular ring 22 is hinged on the base plate 21, the large gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com