Conveying screw device with sealing function and application of conveying screw device

A conveying screw with sealing technology, which is applied in packaging and other directions, can solve the problems of easy leakage and poor discharge, and achieve the effect of reliable sealing, small space occupation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

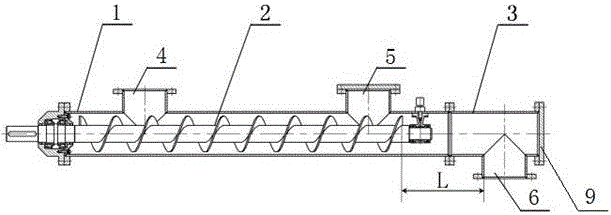

[0017] This example provides figure 1 The shown conveying screw device with sealing function includes a screw outer cylinder 1 and an additional outer cylinder 3. The screw outer cylinder 1 and the additional outer cylinder 3 are connected by bolts, and the wall of the additional outer cylinder 3 A discharge port 6 with an opening downward is provided on the top, a screw shaft 2 is installed in the spiral outer cylinder 1, and a feed port 4 and a feed port 5 with an upward opening are provided on the wall of the spiral outer cylinder 1, and the feed port 4 is set On the side close to the power end of the screw shaft 2 , the feeding port 5 is located near the connection between the screw outer cylinder 1 and the additional outer cylinder 3 .

[0018] figure 1 Shown is the structural diagram of the conveying screw device with sealing function of 25°≤material repose angle≤45°, the working process of the conveying screw device is:

[0019] Before use, connect the feed port 4 to ...

Embodiment 2

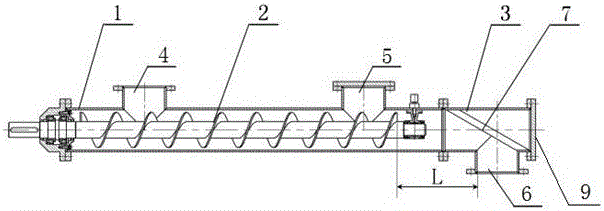

[0022] On the basis of Example 1, such as figure 2 As shown, the additional outer cylinder 3 is provided with an anti-blocking baffle 7, and the anti-blocking baffle 7 is fixed on the inner wall of the additional outer cylinder 3 in an oblique shape, with its inclined surface facing the side of the screw shaft 2, and the discharge port 6 is located below the inclined surface.

[0023] figure 2 Shown is the structural diagram of a conveying screw device with a sealing function with a material repose angle ≥ 45°. The working process of the conveying screw device is:

[0024] Before use, connect the feed port 4 to the discharge port of the pressure vessel, open the feed port 5, add a sufficient amount of plugging material, block the feed port 5, and when the conveying screw is working, the material in the feed port 4 is on the screw shaft. Under the action of 2, the material moves backwards, and the angle of repose of the material is ≥ 45°. Since there is a certain distance L...

Embodiment 3

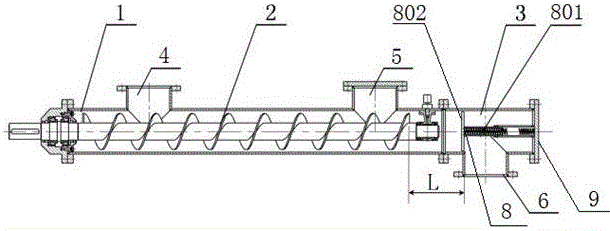

[0026] On the basis of Embodiment 1, the additional outer cylinder 3 is provided with a sealing aid 8, the auxiliary sealing member 8 is composed of a spring 801 and a baffle 802, and one end of the spring 801 is fixed on the bottom plate 9 of the additional outer cylinder 3 , and the other end is fixedly connected with the board surface of the baffle plate 802 .

[0027] image 3 Shown is the structural diagram of the conveying screw device with sealing function with material repose angle ≤ 25°. The working process of the conveying screw device is:

[0028] Before use, connect the feed port 4 to the discharge port of the pressure vessel, open the feed port 5, add a sufficient amount of plugging material, block the feed port 5, and when the conveying screw is working, the material in the feed port 4 is on the screw shaft. Under the action of 2, the material moves backward, the angle of repose of the material is ≤25°, the material moves towards the additional outer cylinder 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com