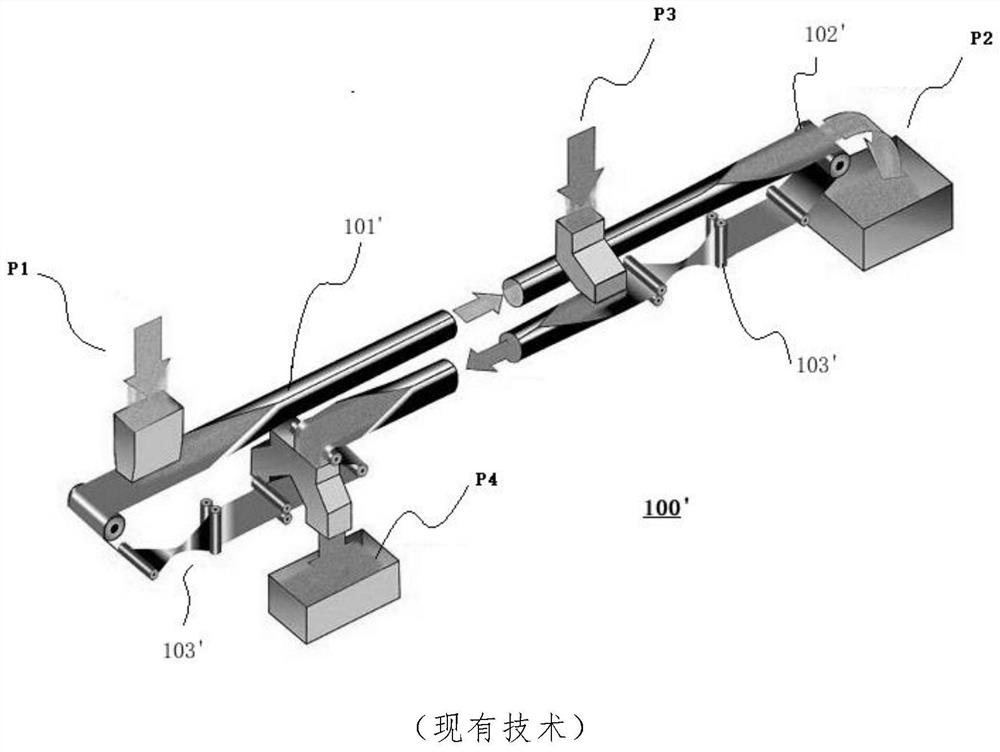

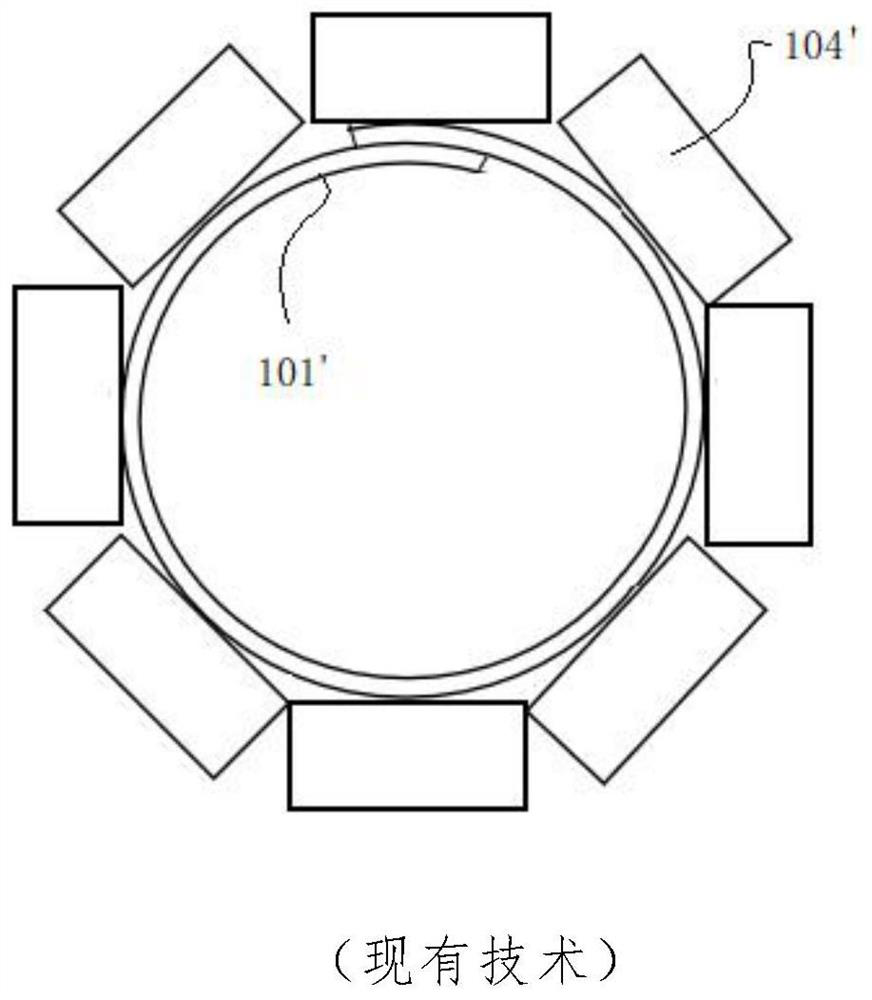

Closed conveying device based on involution closed pipe belt and QHSE operation method

A technology of pipe belt and tubular structure, which is applied in the field of closed conveying device and material conveying pipe belt, can solve the problems of loss of overall flexural performance, complicated mechanical action and high investment cost, achieve simple adaptation to complex terrain and improve system stability , the effect of flexible structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

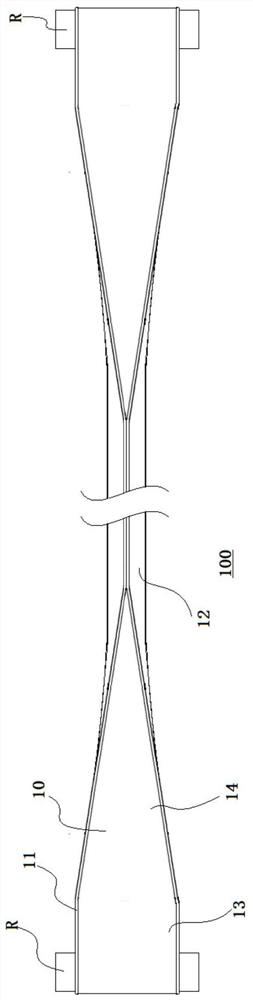

[0041] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0042] In the present invention, the term "width direction" refers to the width direction of the pipe tape. "Longitudinal" refers to the direction in which the pipe belt extends along its length. In engineering practice, the pipe belt will meander and extend according to the landform, natural and social conditions it passes through. Therefore, the longitudinal direction is not a simple straight direction, but follows the pipe belt. Curved and naturally curved. "Vertical" means a direction perpendicular to a support base, usually the direction of gravity.

[0043] The term "coupling" means that the opposing faces of the two edges or edge portions of the strips are affixed relative to each other such that no edge of either strip overlaps staggered beyond its oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com