Environment-friendly pressing belt type continuous ship loader

A ship loader, environmentally friendly technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of mutual pollution of the environment and materials, fixed conveying inclination, poor adaptability, etc., to reduce equipment layout area, reduce The length of the tail car and the effect of shortening the feeding stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

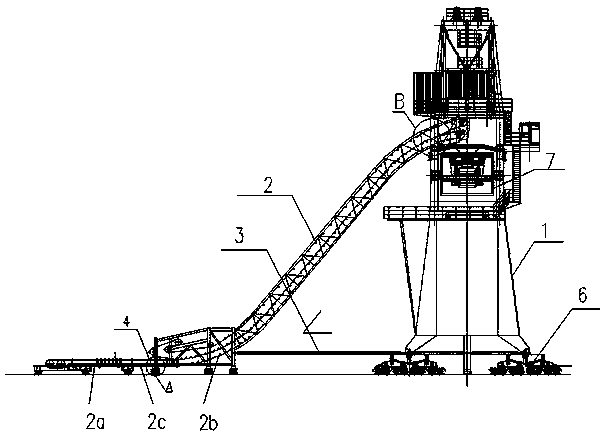

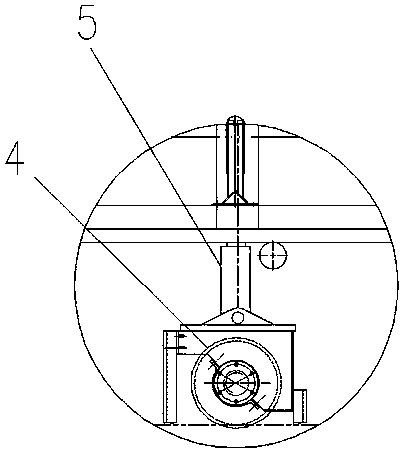

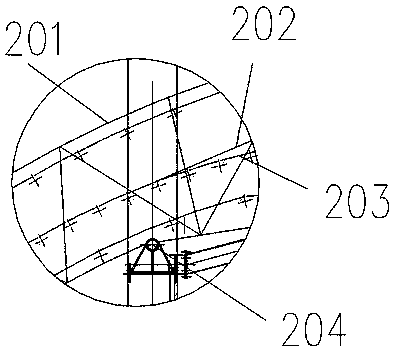

[0017] like Figure 1-4 The shown environment-friendly belt-pressing continuous ship loader includes the main ship loader car 1 and the ship loader tail car, the discharge end of the ship loader tail car is connected with the feed end of the ship loader main car 1, and the ship loader The feed end of the tail car is connected with the ground conveyor, and the tail car of the ship loader is a belt conveyor 2; the belt conveyor 2 includes a truss 201, an upper belt body 202 and a lower belt body that fit together 203, the upper layer belt body 202 and the lower layer belt body 203 are arranged on the idler frame fixedly connected with the truss. The shiploader main vehicle of the shiploader in this embodiment can adopt the conventional arrangement in the prior art, including the boom belt conveyor 7, and the end of the boom belt conveyor 7 is provided with a feeding chute, and the boom belt conveyor can adopt The telescopic belt conveyor and the boom belt conveyor can be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com