Single-soldier rocket launching system capable of being used in limited space

A rocket launch, limited space technology, applied in rocket launch devices, offensive equipment, weapon types, etc., can solve problems such as shooter damage, reduce flame temperature, reduce initial ignition pressure peak, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

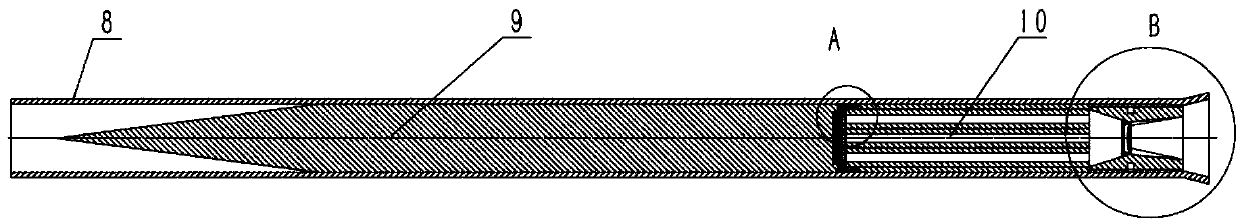

[0030] Embodiment 1, see attached figure 1 , a kind of individual rocket launching system that can be used in limited space, it comprises: rocket launcher 8, rocket warhead 9 and rocket engine combustion chamber 10;

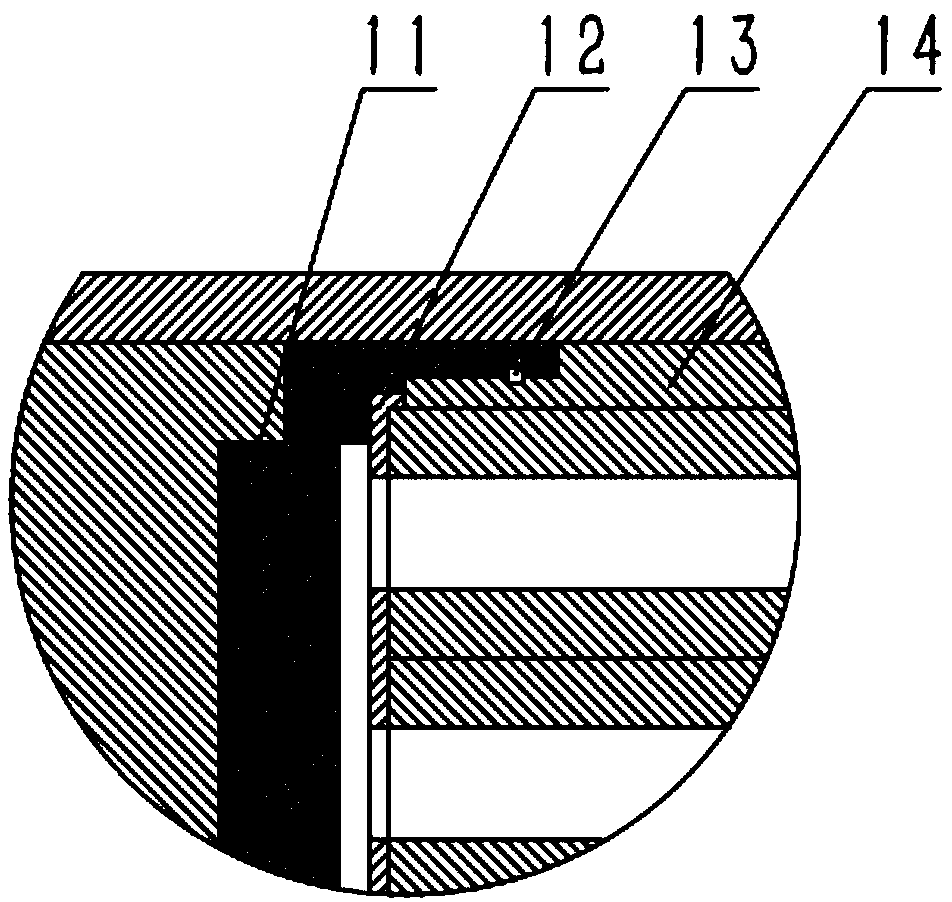

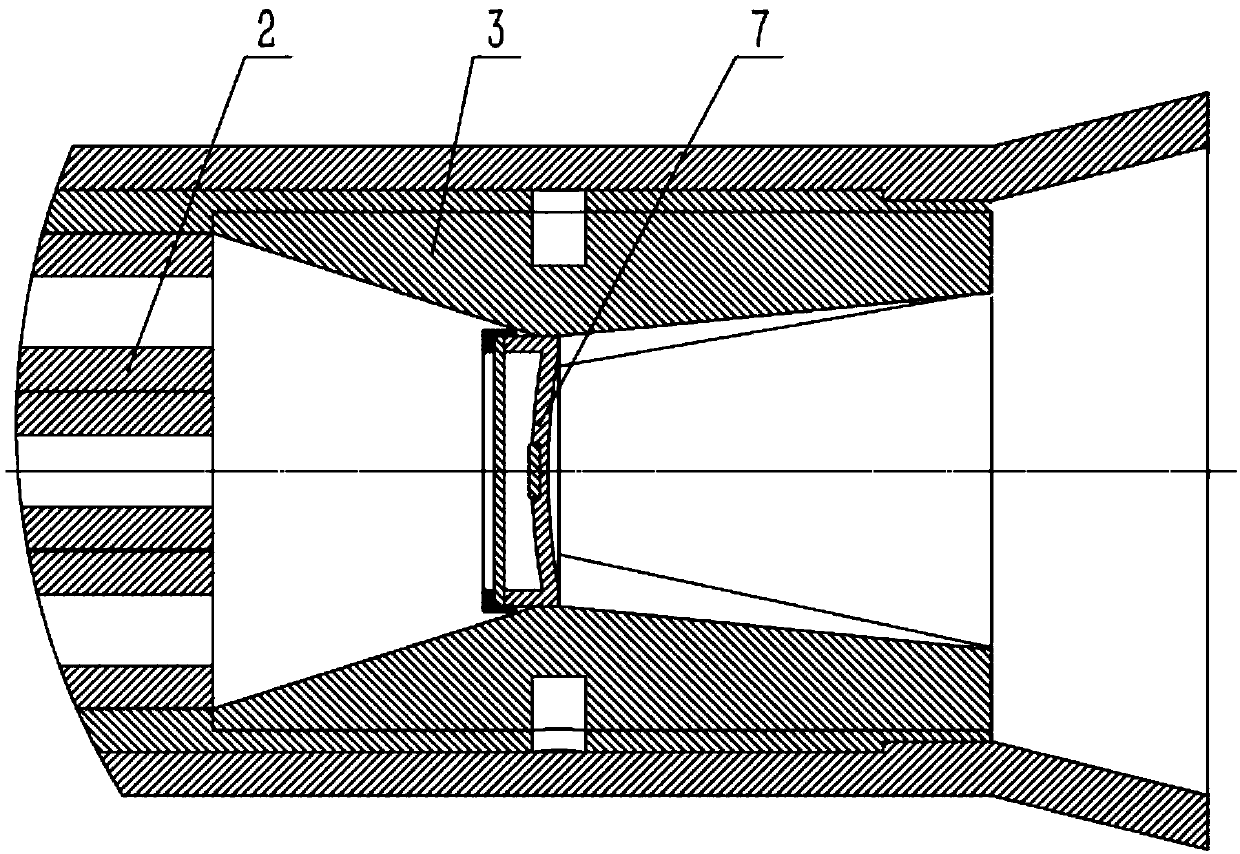

[0031] See attached figure 2 , 3 , 4, the rocket engine combustion chamber 10 comprises: engine housing 14, tube type solid charge 2, charge fixed plate 12, special-shaped nozzle 3 and integral igniter plugging structure 7; tube type solid charge 2 adopts low A thin-walled porous solid propellant grain with a high burning rate; the surface of the charge fixing plate 12 is provided with a vent hole matching the tubular solid charge 2, and an air passage structure is provided at the edge of the charge fixing plate 12, The charge fixing plate 12 has air pressure balance capability; the special-shaped nozzle 3 includes: a circular convergent section, a spray throat and a binary expansion section; the integrated igniter blocking structure 7 includes: an ignition ca...

Embodiment 2

[0034] Embodiment 2, see attached Figure 5 , 6 , 7, on the basis of embodiment 1, further, at the afterbody of rocket launcher 8, also be provided with silencer sleeve 1; Structure 6; wherein: the muffler shell 4 is installed at the tail of the rocket launcher 8, the sound-absorbing interlayer 5 in the barrel is bonded to the inner wall of the muffler shell 4, and the micro-hole plate sound-absorbing structure 6 is installed in the sound-absorbing interlayer 5 in the barrel and passed through The built-in slot of the muffler housing 4 is used for positioning, and the microporous plate muffler structure 6 is provided with a built-in gas channel.

[0035] Further, the binary expansion section of the special-shaped nozzle 3 has a structure of oblique diversion ribs; the exit eaves of the binary expansion section of the special-shaped nozzle 3 is provided with a sawtooth sound-absorbing structure.

[0036]The oblique guide rib structure of the special-shaped nozzle 3 can make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com