Straw rolling machine

A rolling machine, straw technology, applied in the direction of organic fertilizer, etc., can solve the waste of organic fertilizer raw materials and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

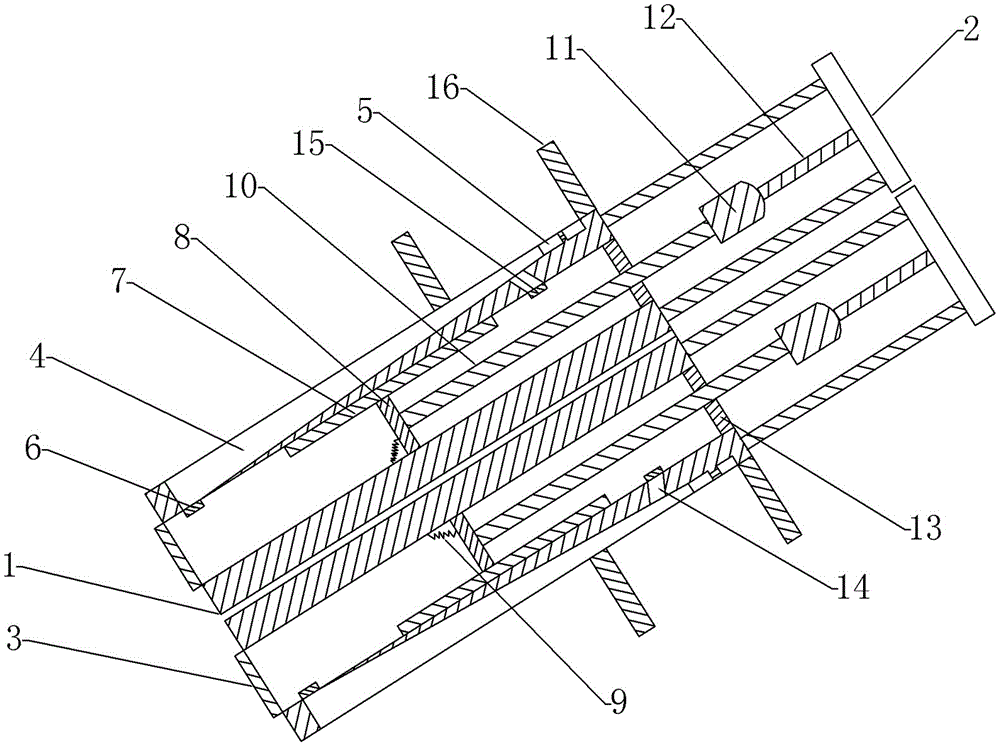

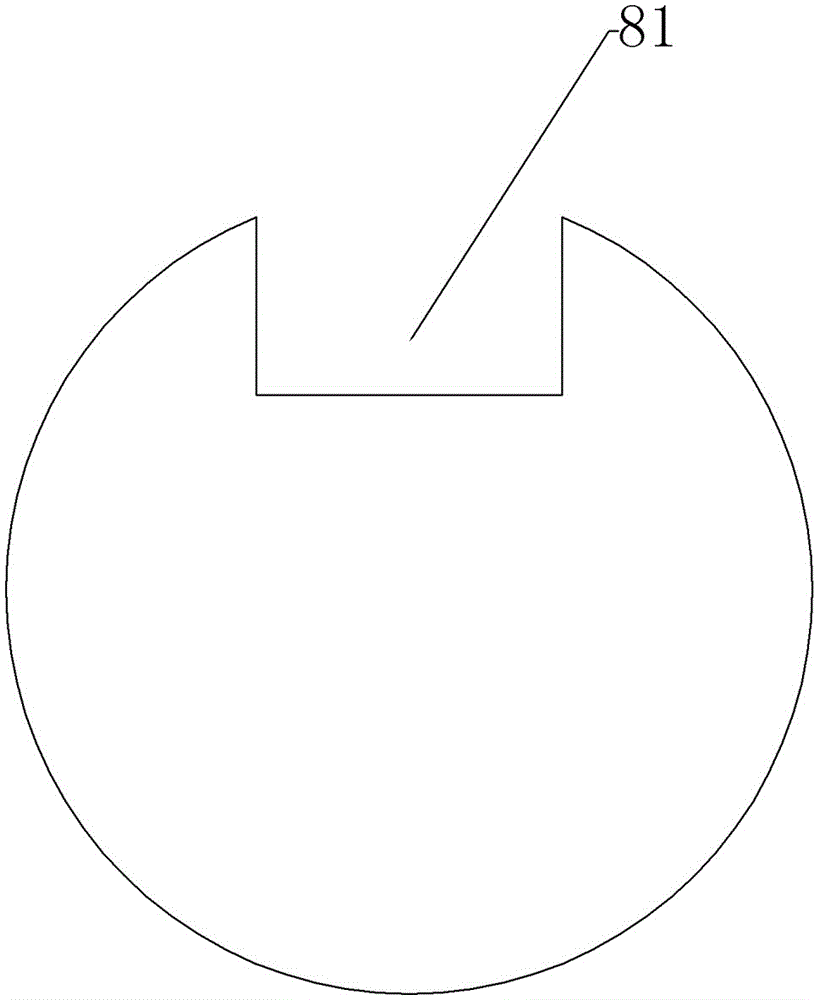

[0019] The reference signs in the accompanying drawings of the description include: squeeze roll 1, rotating motor 2, first pressure valve 3, delivery pipe 4, first groove 5, second pressure valve 6, bump 7, piston plate 8, second Groove 81, return spring 9, support rod 10, cylindrical cam 11, limit rod 12, end cover 13, second through hole 14, third pressure valve 15, positioning plate 16.

[0020] This example figure 1 and figure 2 As shown, a straw rolling machine includes a pair of cylindrical squeeze rollers 1, the squeeze rollers 1 are arranged obliquely and the angle between the squeeze rollers 1 and the horizontal plane is 60°, the upper end of the squeeze rollers 1 passes through the rotating shaft and the rotating motor 2 connected, and the upper opening is provided with an end cover 13, the center of the end cover 13 is provided with a first through hole, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com