An air-suspended proppant for slick water fracturing and its preparation method and use method

A technology of air suspension and water fracturing, which is applied in the direction of chemical instruments and methods, earthwork drilling, and drilling compositions, etc., which can solve problems such as formation damage and reduce reservoir conductivity, so as to reduce damage and reduce Effects of desanding and reducing the displacement of pump trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

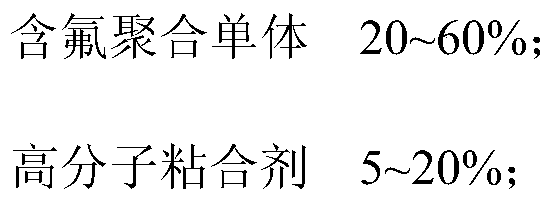

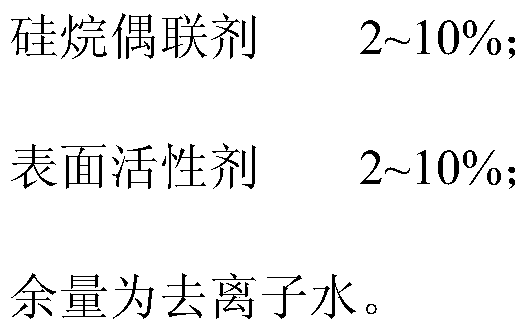

Method used

Image

Examples

Embodiment 1

[0040] (1) Hydrophobic and air-friendly emulsion preparation:

[0041] Raw material: 40.0 g of dodecafluoroheptyl methacrylate (40 wt % of fluorine-containing polymerized monomer);

[0042] Lauryl methacrylate 5.0g, hydroxypropyl acrylate 5.0g, methacrylate-2-(dimethylamino)ethyl 5.0g (high

[0043] Molecular binder 15wt%)

[0044] Vinyltriethoxysilane 7.0g (silane coupling agent 7wt%)

[0045] Polyoxyethylene 2-octylphenol ether-10 3.0g (surfactant 3wt%)

[0046] Deionized water 35.0g (35wt%)

[0047] 1) Mixing the fluorine-containing polymerized monomer, the polymer binder, and the silane coupling agent uniformly in proportion to obtain a raw material mixture;

[0048] 2) Add surfactant and deionized water in proportion to the reactor, stirring at a speed of 600r / min;

[0049] 3) Heating to 75°C under the protection of nitrogen, and then adding the raw material mixture dropwise into the reaction kettle;

[0050] 4) After the dropwise addition, continue the heat preservat...

Embodiment 2

[0058] (1) Hydrophobic and air-friendly emulsion preparation:

[0059] Raw material: 40.0 g of dodecafluoroheptyl acrylate (40 wt% of fluorine-containing polymerized monomer);

[0060] 5.0 g of octadecyl methacrylate, 5.0 g of hydroxypropyl acrylate, 5.0 g of 2-(dimethylamino) ethyl methacrylate (polymer binder 15 wt%)

[0061] Vinyltrimethoxysilane 7.0g (silane coupling agent 7wt%)

[0062] Sodium dodecylbenzenesulfonate 3.0g (surfactant 3wt%)

[0063] Deionized water 35.0g (35wt%)

[0064] 1) Mixing the fluorine-containing polymerized monomer, the polymer binder, and the silane coupling agent uniformly in proportion to obtain a raw material mixture;

[0065] 2) Add surfactant and deionized water in proportion to the reactor, stirring at a speed of 600r / min;

[0066] 3) Heating to 75°C under the protection of nitrogen, and then adding the raw material mixture dropwise into the reaction kettle;

[0067] 4) After the dropwise addition, continue the heat preservation reacti...

Embodiment 3

[0075] (1) Hydrophobic and air-friendly emulsion preparation:

[0076] Raw material: 40.0 g of trifluorooctyl methacrylate (40 wt % of fluorine-containing polymerized monomer);

[0077] 5.0 g of lauryl methacrylate, 5.0 g of hydroxyethyl acrylate, 5.0 g of 2-(dimethylamino) ethyl methacrylate (polymer binder 15 wt %)

[0078] γ-aminopropyltrimethoxysilane 7.0g (silane coupling agent 7wt%)

[0079] Polyoxyethylene sorbitan monostearate 3.0g (surfactant 3wt%)

[0080] Deionized water 35.0g (35wt%)

[0081] 1) Mixing the fluorine-containing polymerized monomer, the polymer binder, and the silane coupling agent uniformly in proportion to obtain a raw material mixture;

[0082] 2) Add surfactant and deionized water in proportion to the reactor, stirring at a speed of 600r / min;

[0083] 3) Heating to 75°C under the protection of nitrogen, and then adding the raw material mixture dropwise into the reaction kettle;

[0084] 4) After the dropwise addition, continue the heat preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com