Evaporation substrate and evaporation method thereof

A substrate and evaporation technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem of affecting the performance of OLED devices, affecting the alignment accuracy of the evaporation substrate and the mask, and offsetting the correct position And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions of the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

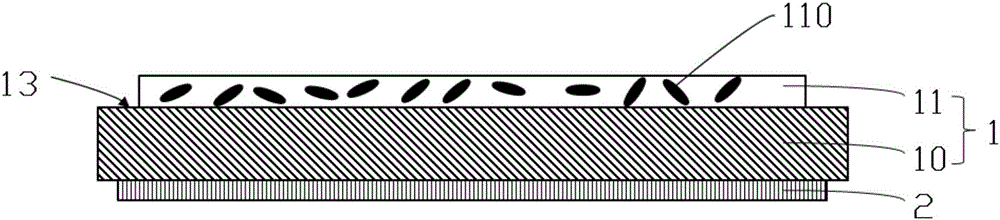

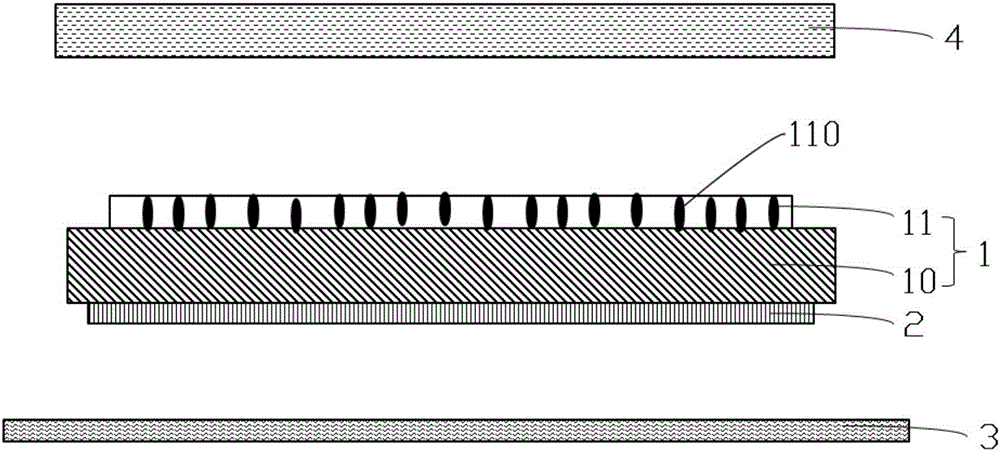

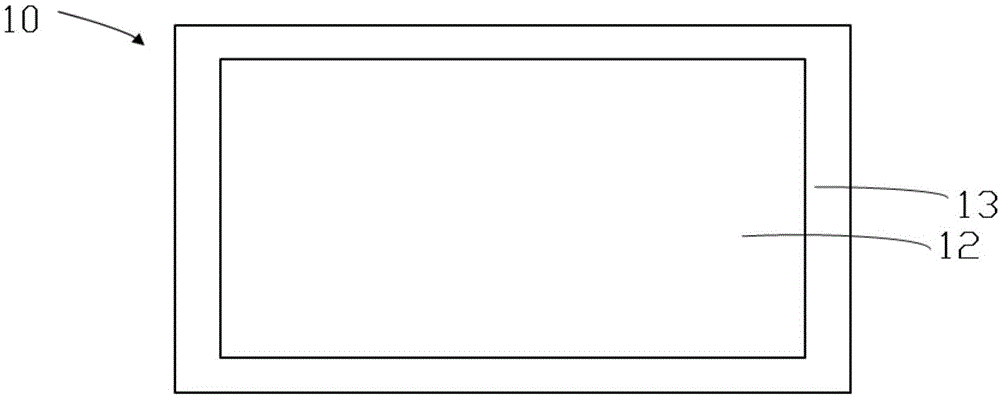

[0033] see figure 1 , figure 1 It is an evaporation substrate 1 provided by the embodiment of the present invention, which is used to align with a metal mask to form and carry an evaporation layer 2, including a substrate 10 and a magnetic layer 11, and the substrate 10 includes a top surface and a The bottom surface, the magnetic layer 11 is arranged on the top surface, and the bottom surface is used to be arranged opposite to the metal mask plate in the evaporation process to form the evaporation layer 2, and the magnetic layer 11 is used to be in contact with the metal mask in the evaporation process. The magnetic devices are oppositely arranged to reduce the sagging of the substrate 10 under the action of magnetic attraction. The magnetic layer 11 can be distributed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com