Reinforcing structure at bridge pier of steel box girder and construction method of steel box girder with structure

A technology for strengthening structures and steel box girders, which can be used in bridge reinforcement, bridges, connecting components, etc., can solve the problems of inability to inspect high-tensile bolts and nuts for loosening, increased cost of steel box girders, and difficulty in maintenance and management. The effect of easy maintenance, increased life, and increased durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

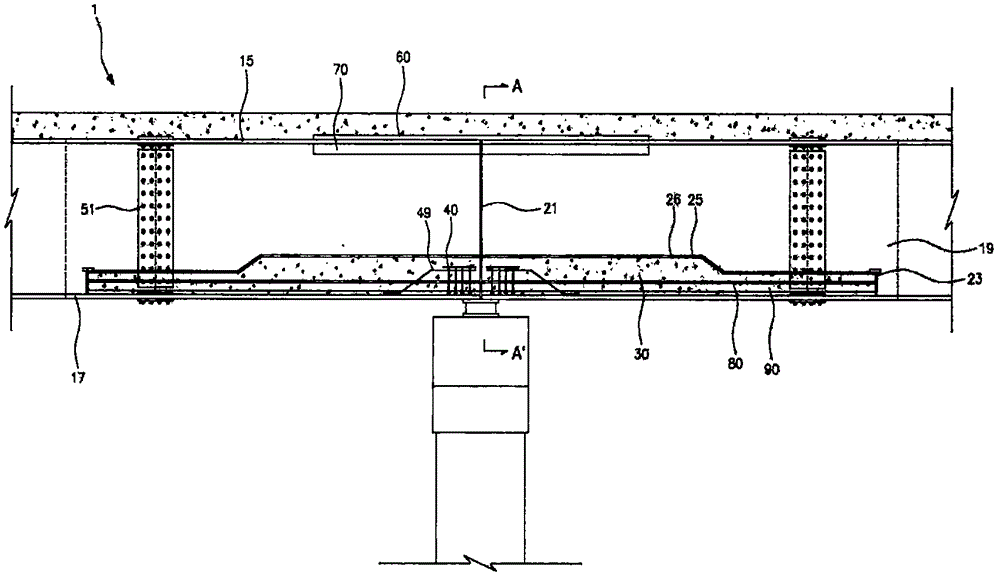

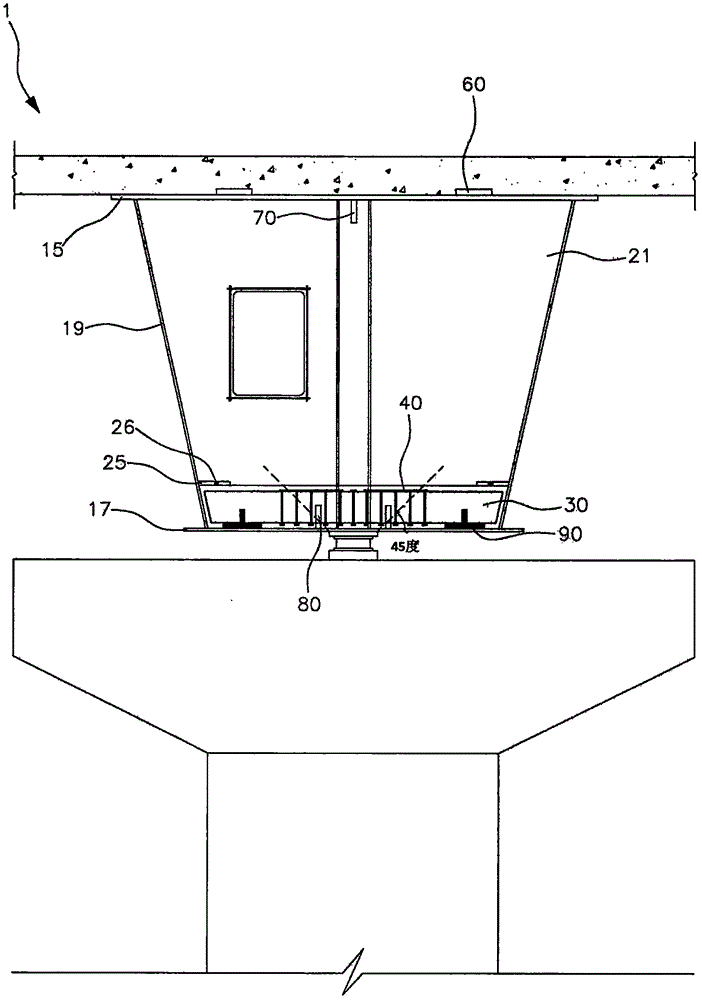

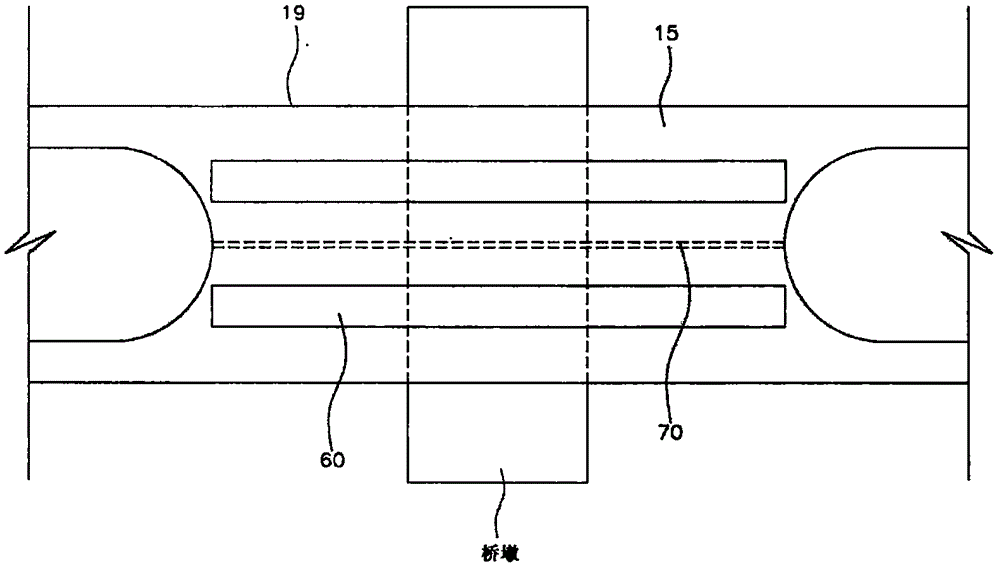

[0055] refer to Figure 1a to Figure 2d, according to an embodiment of the present invention, the steel box girder (1) bridge pier double composite reinforcement structure can be formed on the lower flange (17) of the steel box girder (1) negative bending moment interval formed by connecting several unit sections, Pouring high-strength concrete (30) and installing several punching reinforcement clips (40) and shear reinforcement bars (49). The above-mentioned steel box girder (1) unit section is connected by high tensile bolts (51) and nuts (53), and the upper flange (15) of the steel box girder (1) can also be combined with the upper flange reinforcement (60), The upper flange reinforcement ribs (70) etc. can also be combined with the lower flange reinforcement ribs (80), lower flange reinforcements (90) etc. at the lower flange (17). The steel box girder (1) is composed of several unit sections connected by the upper flange (15), the lower flange (17) and the abdomen (19), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com