A vehicle-mounted fully automatic highway guardrail cleaning system

A technology for highway guardrails and cleaning systems, which is applied in road cleaning, cleaning methods, construction and other directions, can solve the problem of not being able to adjust the working distance of air jets, water jets and guardrails, difficulty in cleaning guardrails, and limited high-pressure air pressure. and other problems, to achieve the effect of significant cleaning effect, reduction of work cost, and reduction of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

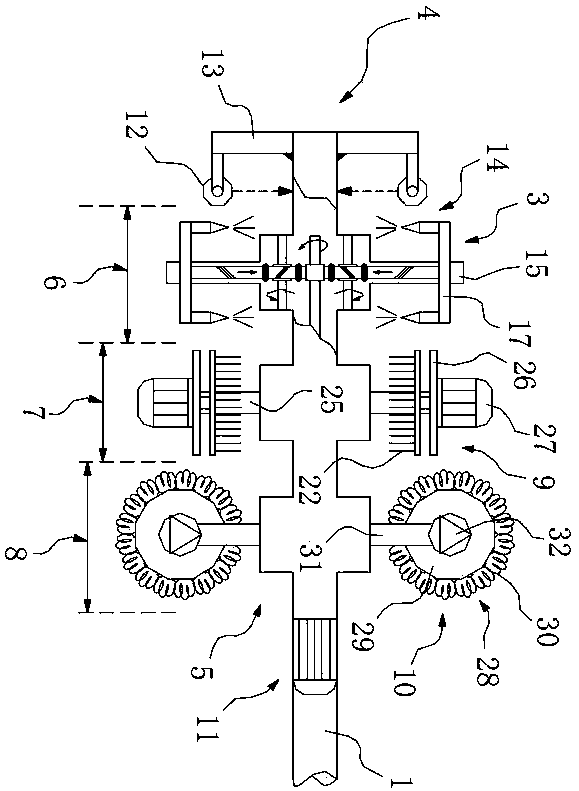

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

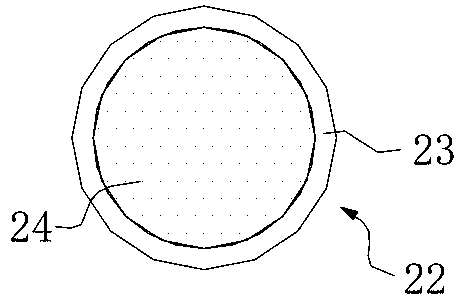

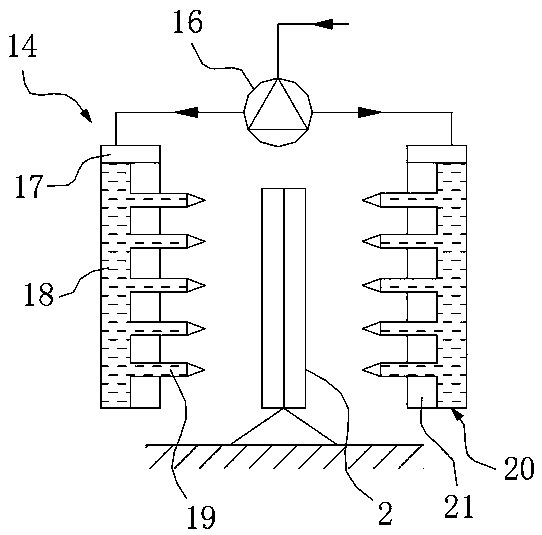

[0022] Such as figure 1 , 2, Shown in 3 and 4, a vehicle-mounted full-automatic road guardrail cleaning system includes a cleaning support 1 that is used to be connected with the cleaning operation vehicle, and a water spray mechanism 3 for washing the guardrail 2 is arranged on the cleaning support 1, so that The cleaning bracket 1 is divided into a cleaning section 6, a scrubbing section 7 and a drying section 8 successively from the front end 4 to the rear end 5. The water spray mechanism 3 is arranged on the cleaning section 6. The brush mechanism 9 that washes the guardrail 2 after the water mechanism 3 rinses, the drying section 8 is provided with a drying mechanism 10 that wipes the guardrail 2 after the guardrail 2 is washed by the brush mechanism 9, and is set on the cleaning support 1 There are detection elements for detecting the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com