Concrete panel crushing failure repairing structure and construction method

A technology for concrete panels and repairing structures, applied in water conservancy projects, marine engineering, dams, etc., can solve problems such as repeated extrusion damage, and achieve the effect of great promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

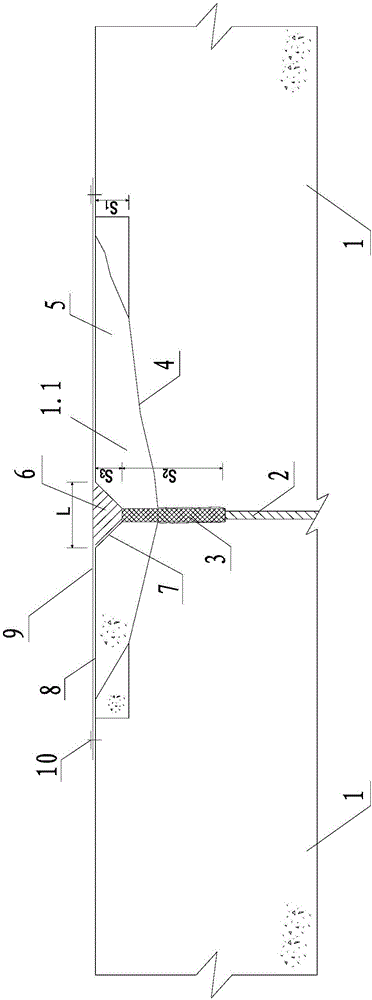

[0020] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

[0021] refer to figure 1 Shown: a concrete panel extrusion damaged repair structure, there is a vertical seam 2 on the concrete panel 1, a rubber plate 3 is installed on the middle and upper part of the vertical seam 2, and there is a concrete panel above the vertical seam 2 In the damaged area 1.1, the concrete in the damaged area 1.1 of the concrete panel is excavated in advance and the repair material 5 is filled; a V-shaped groove 7 is reserved on the top of the vertical joint 2, and plastic materials are filled in the V-shaped groove 7 6. An anti-seepage cover sheet 9 is provided on the concrete panel 1 above the vertical joint 2, and both sides ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com