High-carbon iron-based amorphous alloy transformer core and manufacturing method thereof

An iron-based amorphous alloy, transformer core technology, applied in the direction of transformer/inductor magnetic core, etc., can solve the problems of core temperature rise, insulation layer aging, loss increase, etc., to achieve less heat generation, not easy to aging, Low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

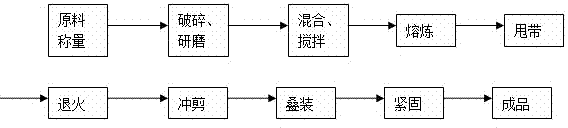

[0033] Example 1: Press figure 1 Shown, the production raw material and proportioning are:

[0034] Iron: 82%

[0035] Carbon: 6%

[0036] Silicon: 5%

[0037] Boron: 7%.

[0038] The manufacturing process of high carbon iron-based amorphous alloy transformer core is as follows:

[0039] (1) Weigh various raw materials as required;

[0040] (2) Crushing and grinding blocky raw materials;

[0041] (3) Put various raw materials into the container and mix and stir to make the ingredients uniform;

[0042] (4) Pour the uniformly mixed raw materials into a crucible and put them into a smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room temperature, and raise the temperature with the furnace; the heating temperature is 1350 ° C, and the heat preservation time is 10 Hour;

[0043] (5) The alloy liquid is sprayed onto the cooling roller rotating at high speed, and the strip is thrown...

Embodiment 2

[0048] Example 2: Press figure 1 Shown, the production raw material and proportioning are:

[0049] Iron: 85%

[0050] Carbon: 5%

[0051] Silicon: 4%

[0052] Boron: 6%.

[0053] The manufacturing process of high carbon iron-based amorphous alloy transformer core is as follows:

[0054] (1) Weigh various raw materials as required;

[0055] (2) Crushing and grinding blocky raw materials;

[0056] (3) Put various raw materials into the container and mix and stir to make the ingredients uniform;

[0057] (4) Pour the uniformly mixed raw materials into a crucible and put them into a smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room temperature, and raise the temperature with the furnace; the maximum heating temperature is 1400 ° C, and the heat preservation 8 hours;

[0058] (5) The alloy liquid is sprayed onto the cooling roller rotating at high speed, and the strip is thrown...

Embodiment 3

[0063] Embodiment 3: press figure 1 Shown, the production raw material and proportioning are:

[0064] Iron: 88%

[0065] Carbon: 6%

[0066] Silicon: 3%

[0067] Boron: 3%.

[0068] The manufacturing process of high carbon iron-based amorphous alloy transformer core is as follows:

[0069] (1) Weigh various raw materials as required;

[0070] (2) Crushing and grinding blocky raw materials;

[0071] (3) Put various raw materials into the container and mix and stir to make the ingredients uniform;

[0072] (4) Pour the uniformly mixed raw materials into the crucible and put them into the smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room temperature, and raise the temperature with the furnace; the maximum heating temperature is 1450 ° C, and the heat preservation 15 hours;

[0073] (5) The alloy liquid is sprayed onto the cooling roller rotating at high speed, and the strip is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com