Water-saving synergic self-controlled hydraulic cutting head

A cutting head and hydraulic technology, which is applied in the field of water-saving and efficiency-enhancing self-control hydraulic cutting heads, can solve the problems of reduced work efficiency, small working space, large energy loss, etc., so as to reduce the waste of water resources and energy and avoid flooding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

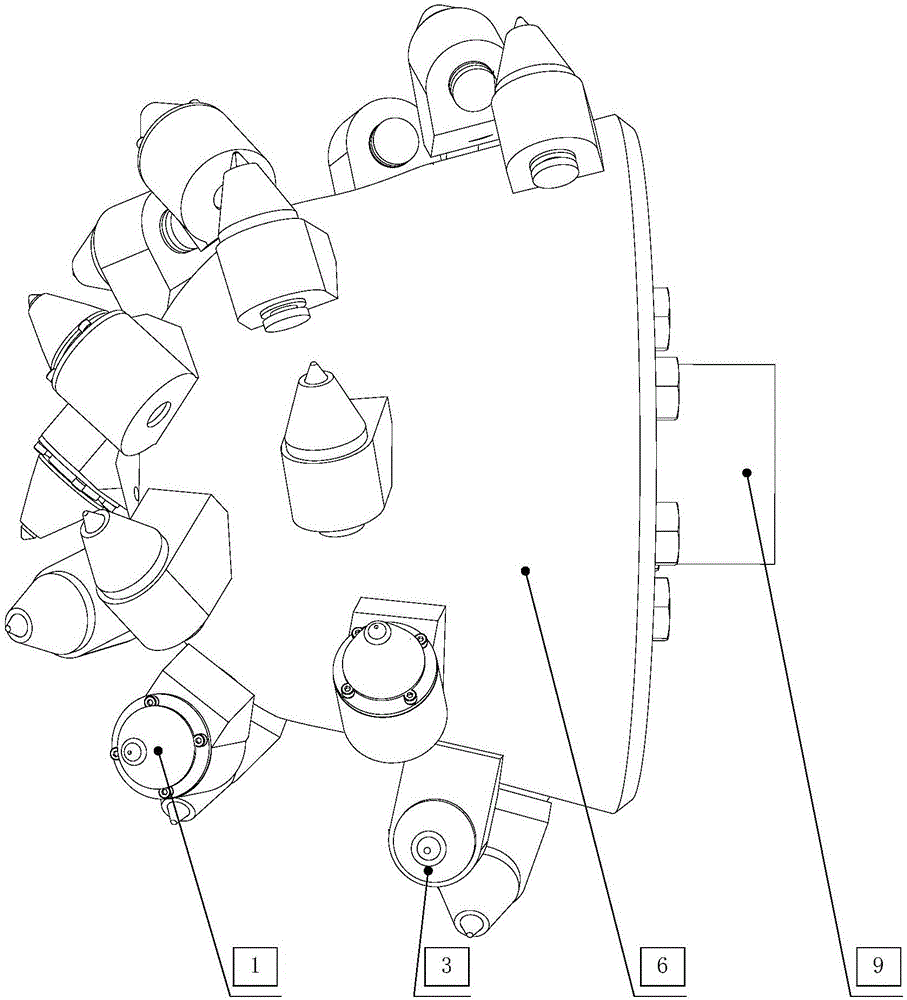

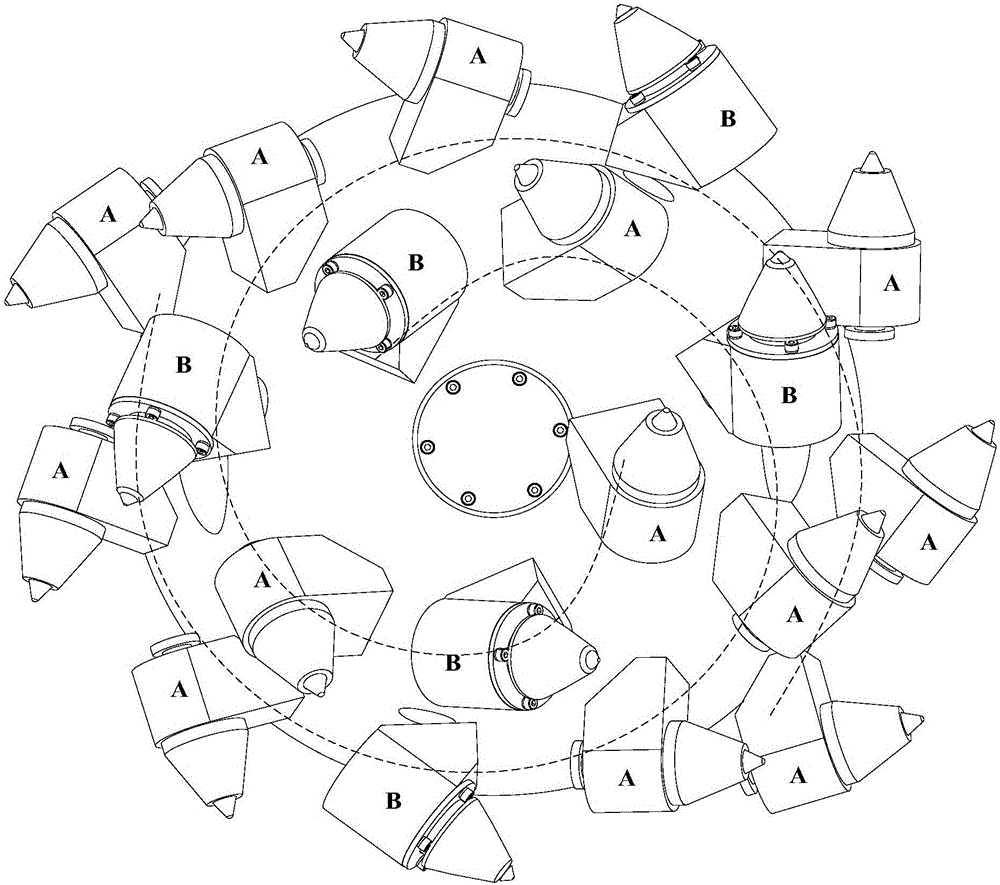

[0032] The self-controlled hydraulic cutting head with water-saving and efficiency-enhancing capabilities of the present invention includes a cutting head body 6, the cutting head body 6 is a hollow structure, and the outer contour surface of the cutting head body 6 is used to place a welding automatic hydraulic cutting head. The pick 1 and the common pick 3 are provided with a connecting flange on the right side and are connected to the drive shaft 10 through a coupling 9 .

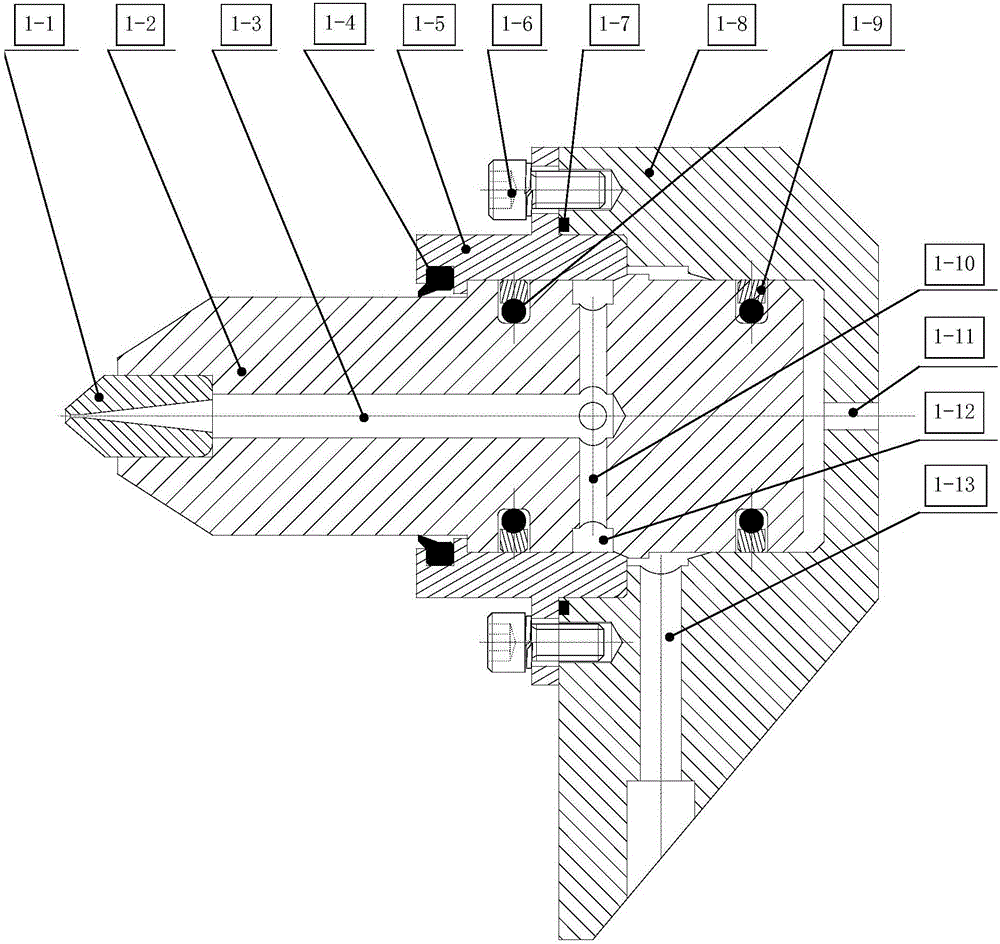

[0033] The self-controlling hydraulic pick 1 can be found in the patent: a water-saving and synergistic hydraulic pick (patent number: CN201610453901.5), in which a nozzle 1-1 is set at the tooth tip of the self-controlling hydraulic pick 1, and the middle of the tooth body 1-2 Set the central water channel 1-3, set the radial flow channel 1-10 and the annular groove 1-12 near the end; Axially s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com