A remote pressure relief structure for solid-liquid rocket motor

A technology of solid-liquid rocket and pressure relief structure, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as personnel or equipment danger, and achieve the effect of small impact on equipment, reduced impact, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

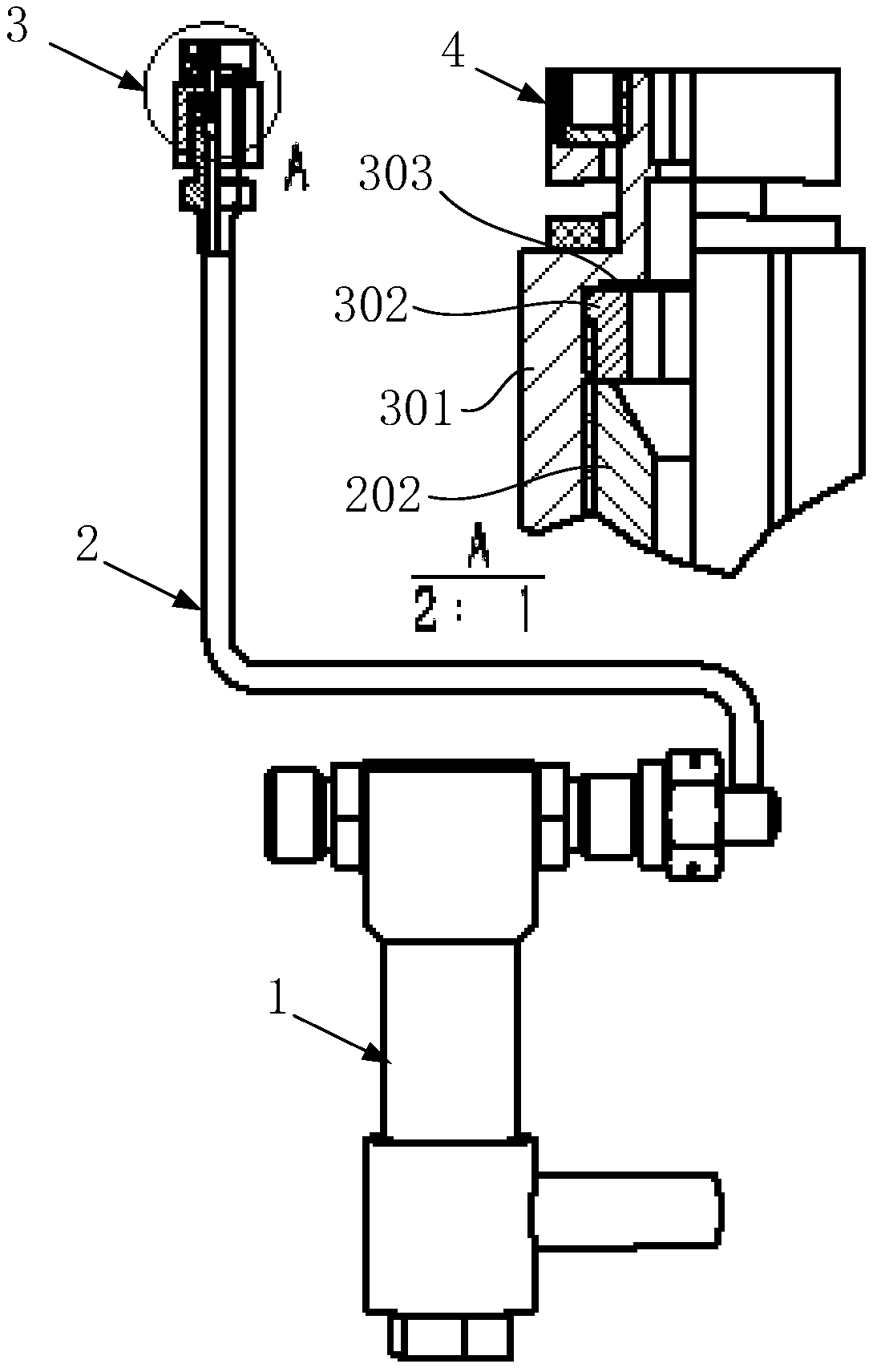

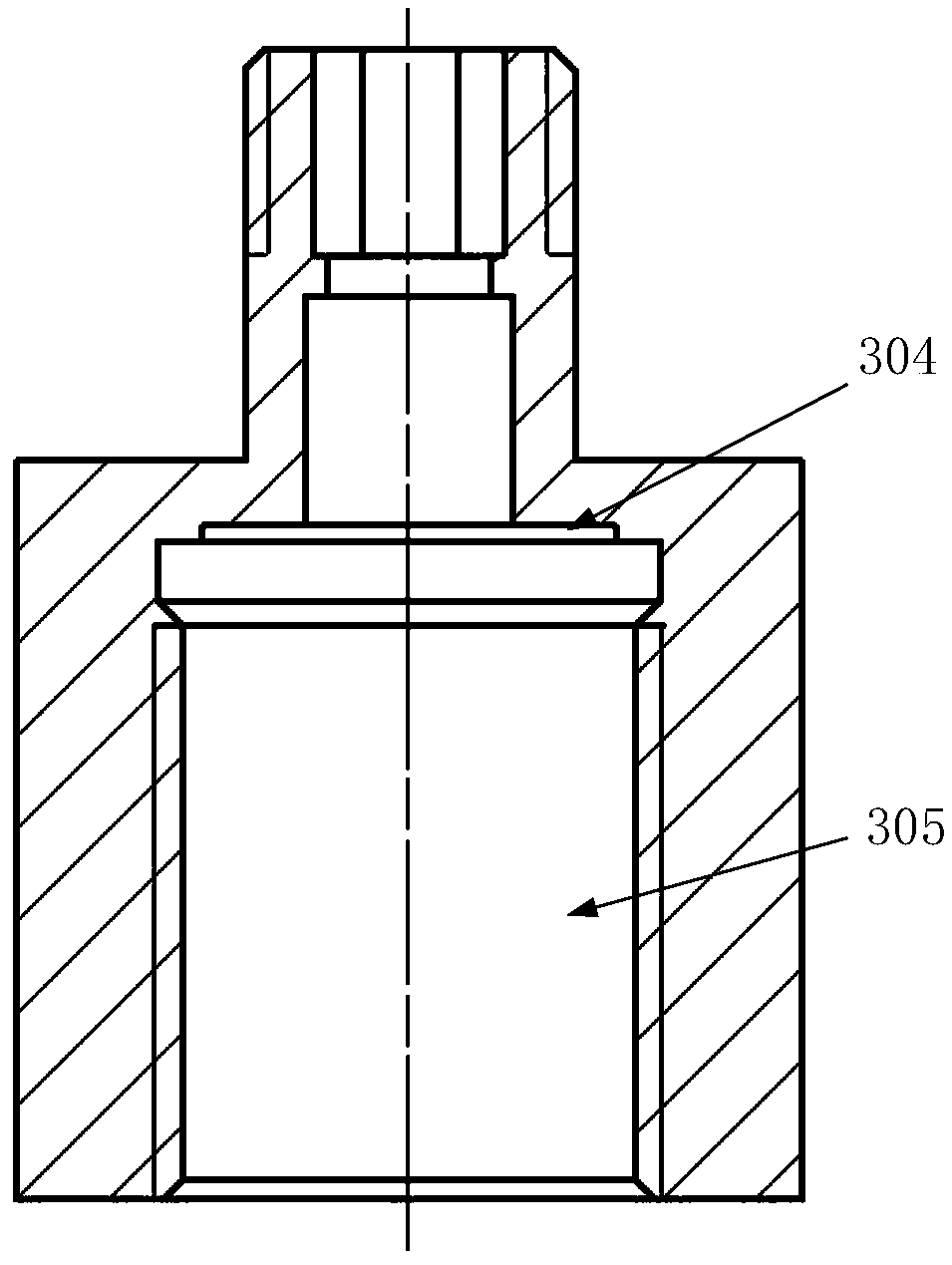

[0027] The present invention proposes a remote pressure relief structure for a solid-liquid rocket engine, which is used for remote pressure relief of high-pressure gas, including a remote pressure relief solenoid valve 1, a pressure relief pipeline 2, and a discharge assembly 3, such as figure 1 shown.

[0028] The remote pressure relief solenoid valve 1 is used to control the discharge of high-pressure gas in the gas cylinder. Its inlet end is connected to the gas cylinder, and its outlet end is connected to the pressure relief pipeline 2. The solenoid valve 1 guides the flow to the discharge assembly 3 installed on the skin of the solid-liquid rocket motor.

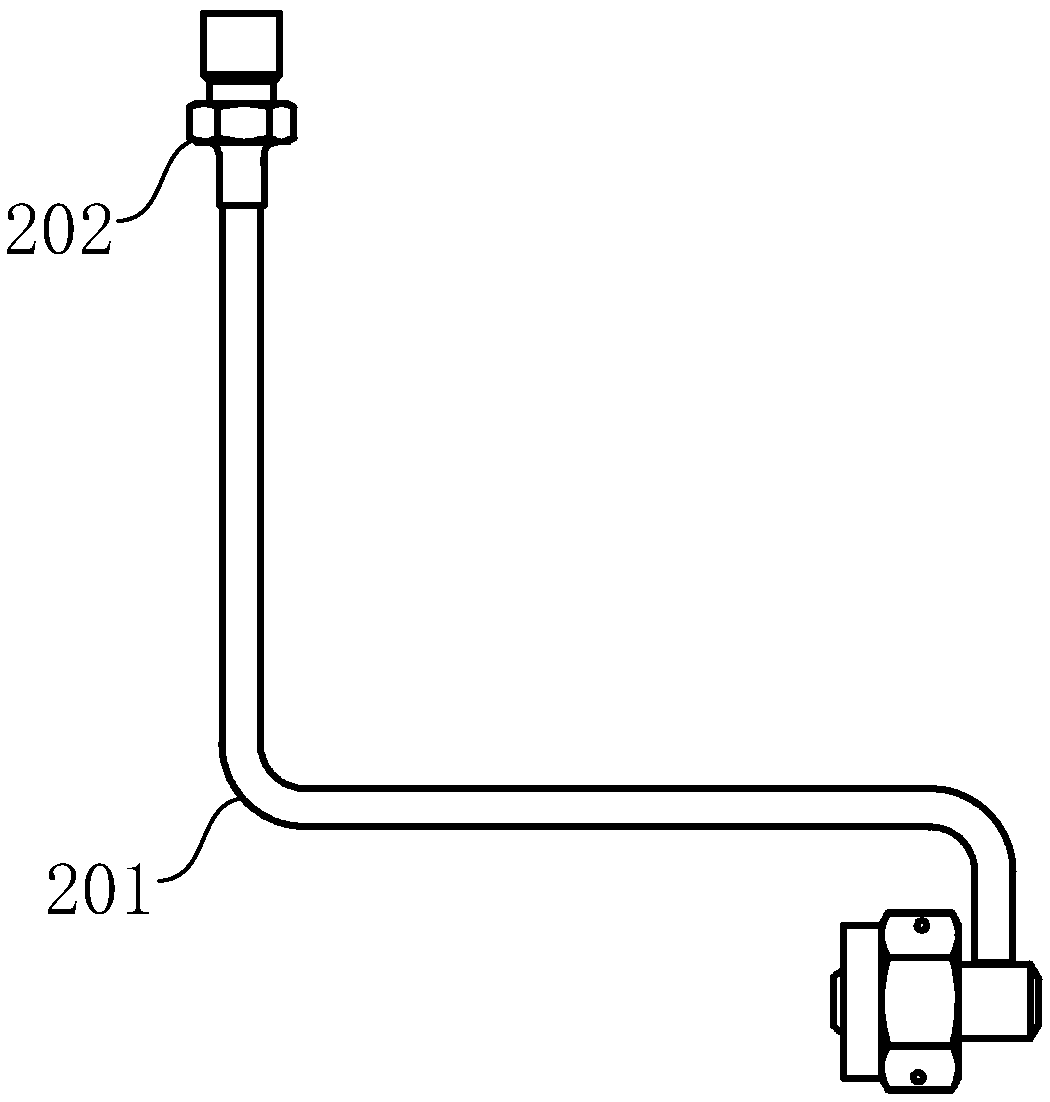

[0029] The pressure relief pipeline 2 is made of stainless steel, and is composed of an elbow 201 and a welding nozzle 202, such as figure 2 shown. Wherein, the inlet end of the elbow 201 is coaxially insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com