An electronically controlled single pump solenoid valve drive circuit and its control method

A technology of solenoid valve drive and single pump, applied in the direction of program control, computer control, general control system, etc., can solve the problems of serious resistance temperature drift, many operational amplifier circuits, and easy to be interfered, and achieve good output linearity and response The effect of less time and less working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

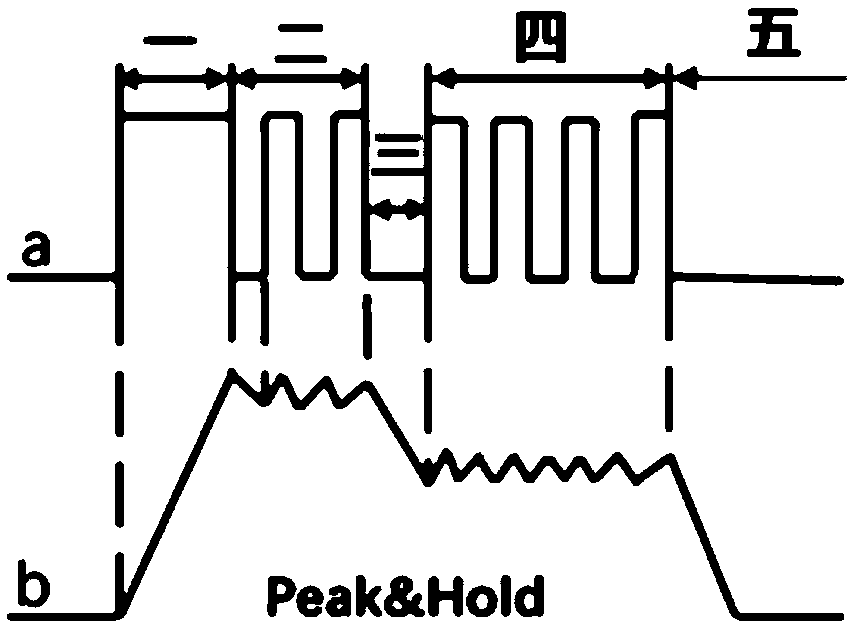

[0027] figure 1 The solenoid valve of the electronically controlled unit pump is shown in the Peak&Hold drive mode, which is divided into five stages: the first stage that needs to supply a large voltage to make the solenoid valve close quickly, the second stage that maintains the peak voltage so that the valve can quickly seat, and the peak The third stage of the transition from voltage to low voltage, the fourth stage of low voltage maintenance to maintain the closed state of the solenoid valve, and the fifth stage of rapid discharge; in the second and fourth stages, it is necessary to cooperate with Hall current sensors to accurately control voltage fluctuations, Cooperate in the fifth stage figure 2 The bleeder circuit in ( figure 2 The dotted line in the middle) realizes the rapid discharge of the solenoid valve.

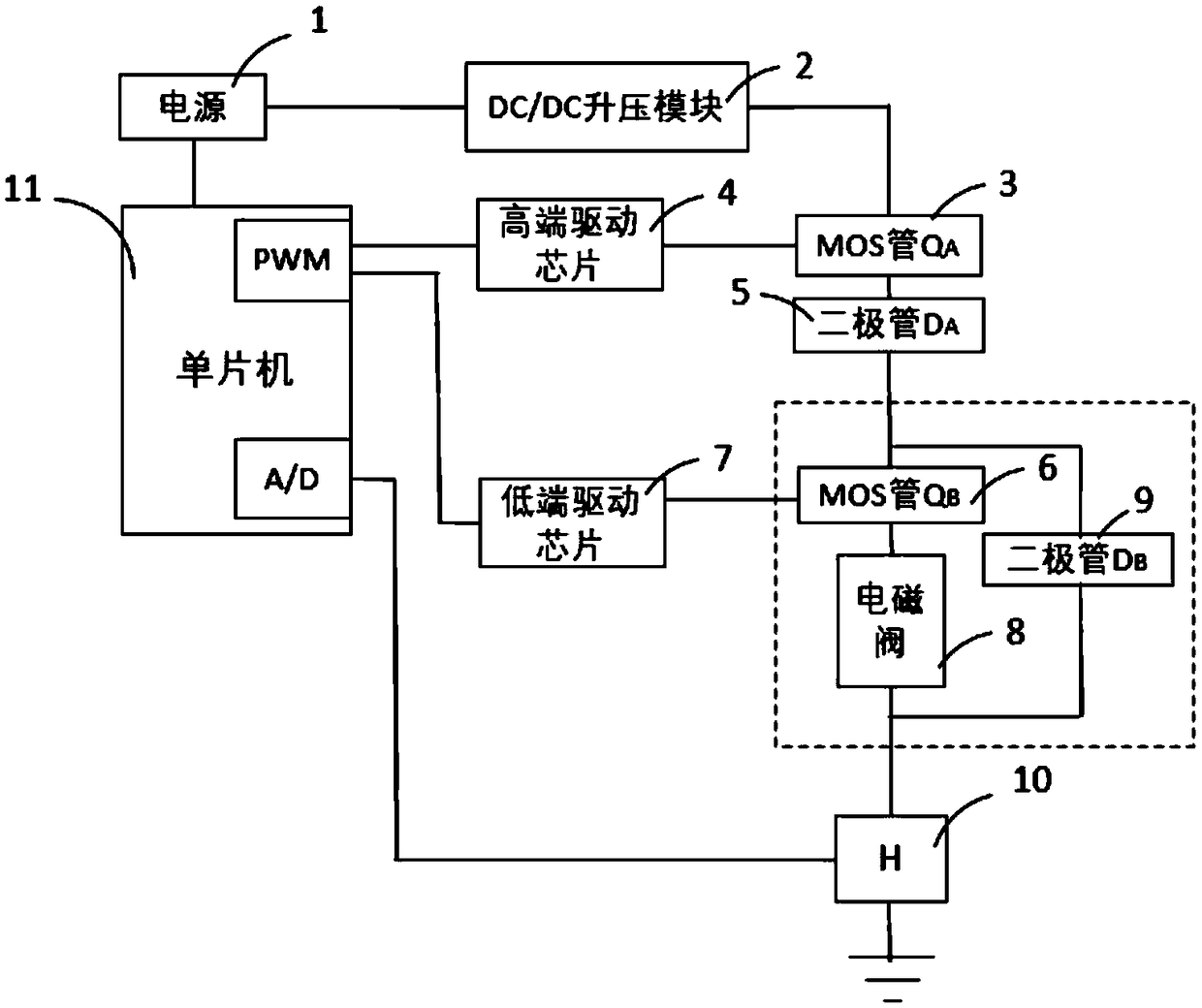

[0028] figure 2 Shown is the solenoid valve driving circuit of the present invention, including a power supply 1, a DC / DC boost module 2, and a MOS tube ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap