Energy-saving type gas burner and gas stove

A gas stove, energy-saving technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as low energy efficiency of gas stoves, and achieve the effects of avoiding air pollution, saving energy, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below with reference to the accompanying drawings.

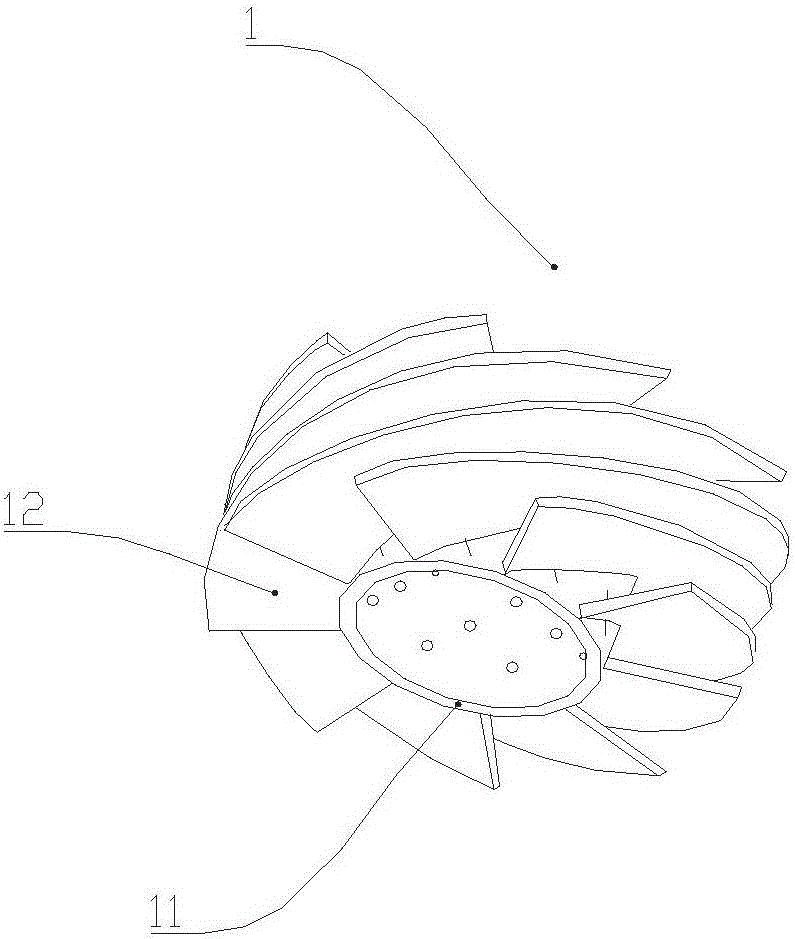

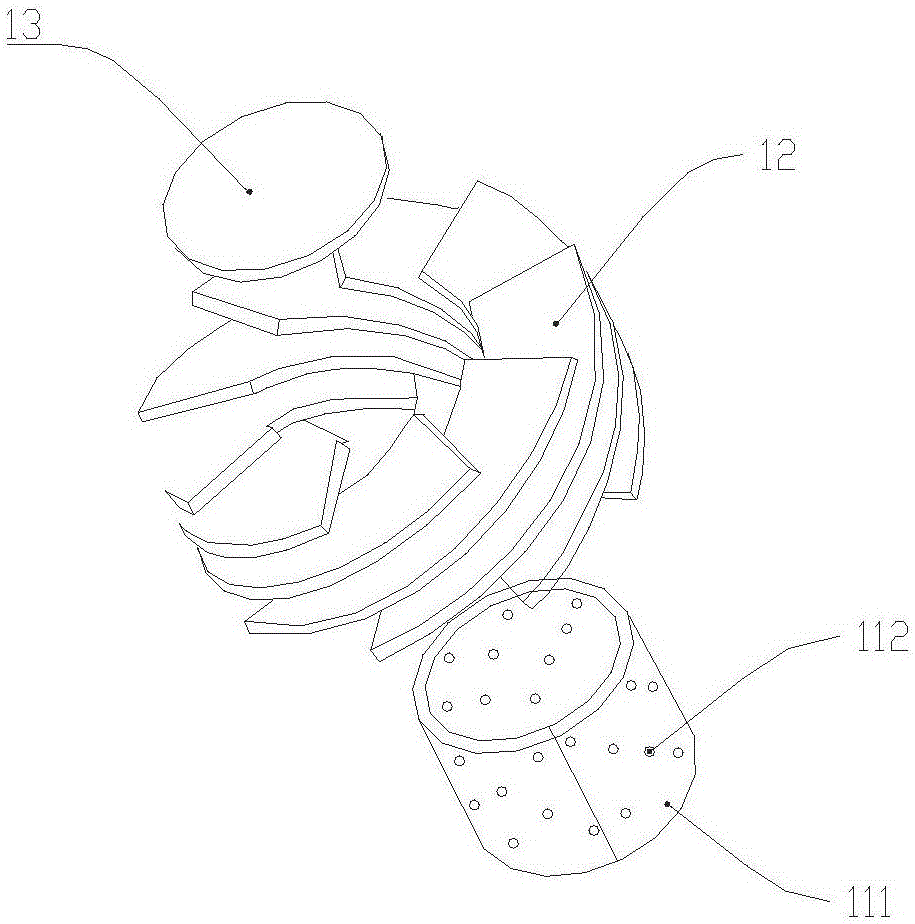

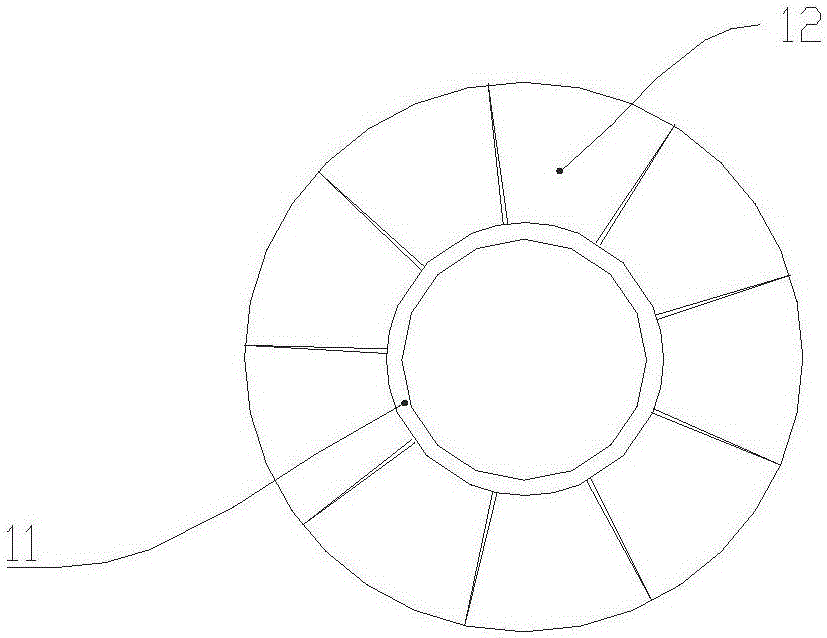

[0023] Please refer to the attached figure 1 to attach Figure 7 , in this embodiment, the energy-saving gas burner head includes: a rotary leaf wheel 1, and the rotary leaf wheel 1 includes a gas head 11 and several rotating shafts extending from the bottom end of the side wall of the gas head 11 to the top. The sheet 12, wherein the side wall of the gas head 11 is also provided with a plurality of through holes 112 for gas circulation. The gas fluid first enters the gas head 11, then flows out through the through hole 112, and after being rotated and dispersed by the above-mentioned rotating sheet 12, it is fully burned in contact with the air.

[0024] Further, please refer to the attached figure 2 , the gas head 11 includes a barrel-shaped body 111, a port of the barrel-shaped body 111 is provided with a top cover 13, the role of the top cover 13 makes the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com