Cold storage combined refrigeration control method, device and cold storage engineering system

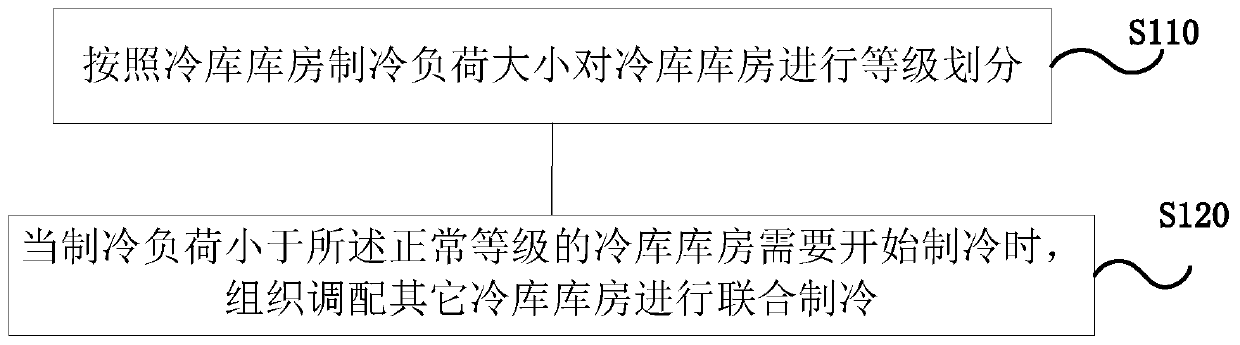

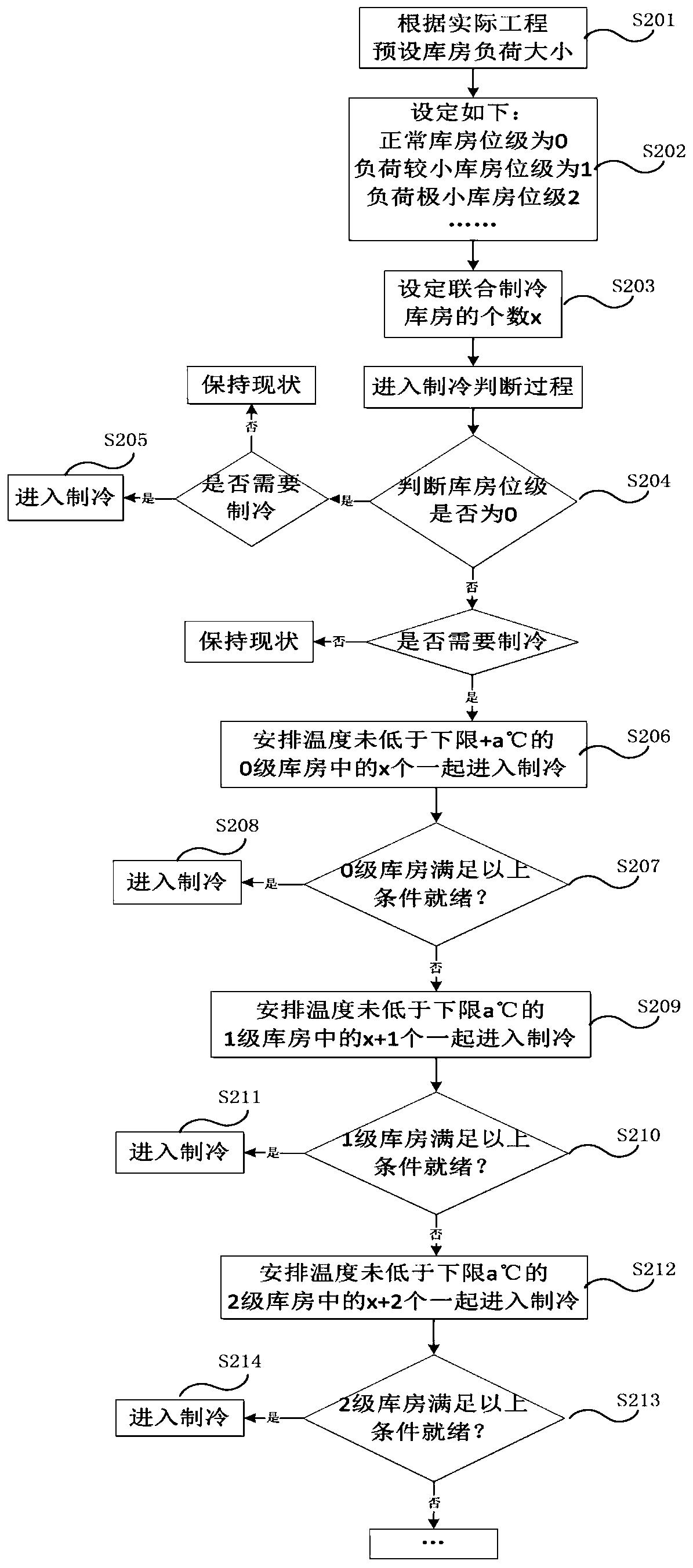

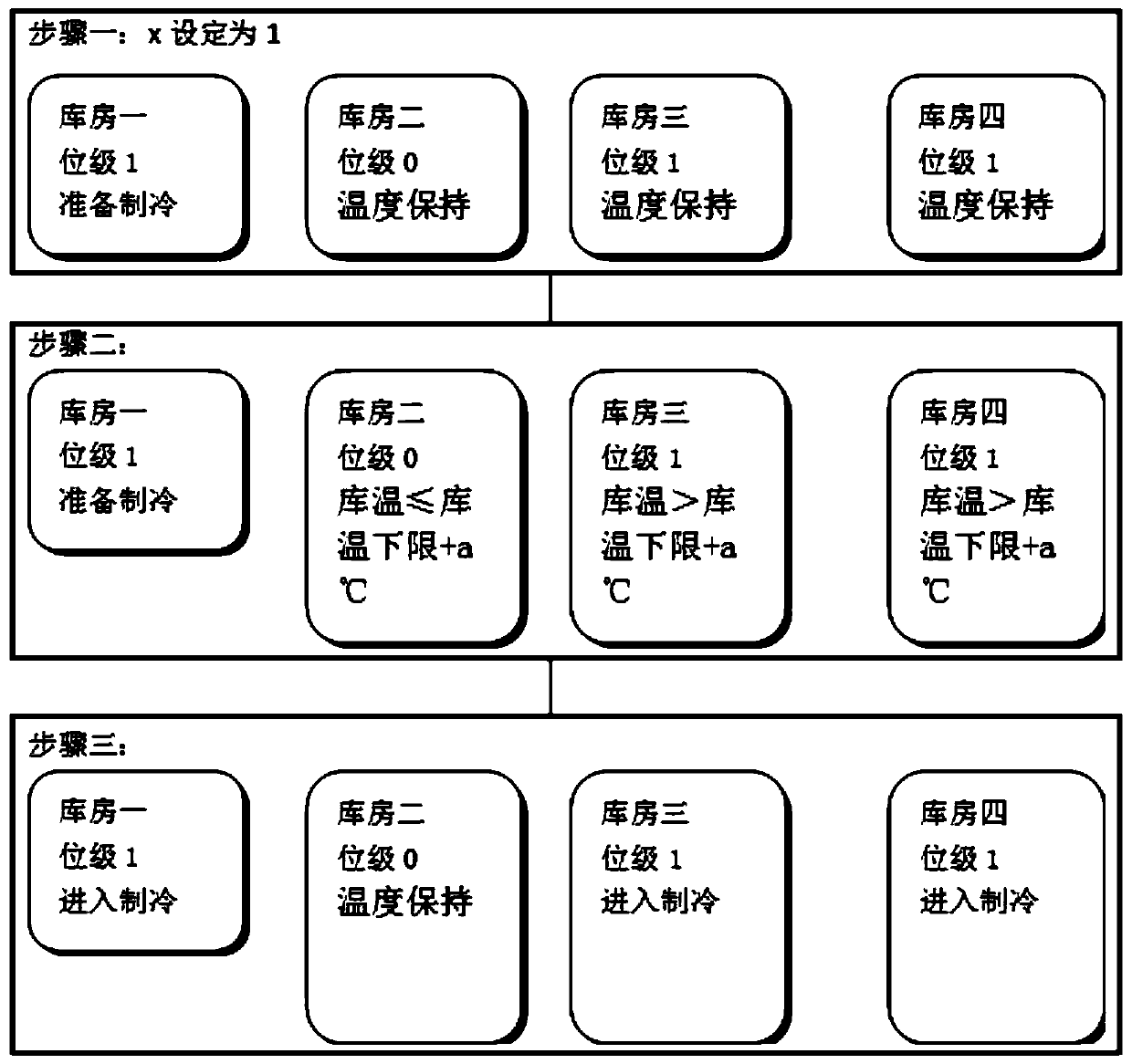

A technology of combined refrigeration and control methods, which is applied in the direction of household refrigeration devices, coolers, and cold storage rooms, can solve the problems of not involving the specific control method of ambient temperature, the inability to meet precise control requirements, and the lack of linkage between warehouses and warehouses. The refrigeration and cooling process is stable and rapid, which is beneficial to the overall management and deployment, and avoids the effect of excessive pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] According to an implementation manner of the combined refrigeration control device for the refrigerator of the present invention, n=2.

[0052] Another aspect of the present invention also provides a cold storage engineering system, which has the combined refrigeration control device for cold storage described in any one of the above items.

[0053] The technical solution provided by the invention integrates and concentrates the refrigeration loads of all warehouses to cool down together through the linkage between warehouses, avoiding too frequent load adjustment of the refrigeration host, and avoiding long-term operation at low-load operation with low energy efficiency; to a large extent In order to avoid the phenomenon of excessive pressure drop, frequent start-up of the refrigeration main engine, discontinuous cooling process, and long cooling time, it can ensure that the warehouse with a small cooling load can carry out the normal and continuous cooling process; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com