Pneumatic ash conveying control method

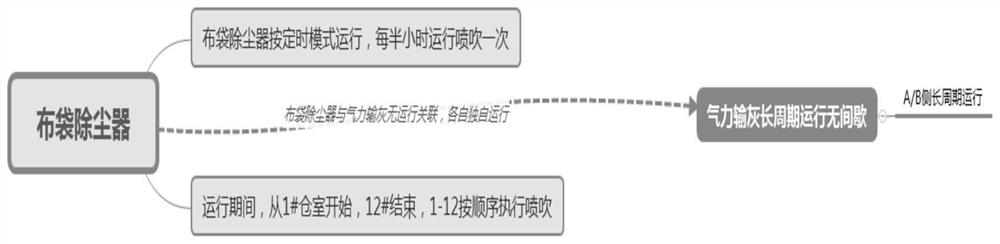

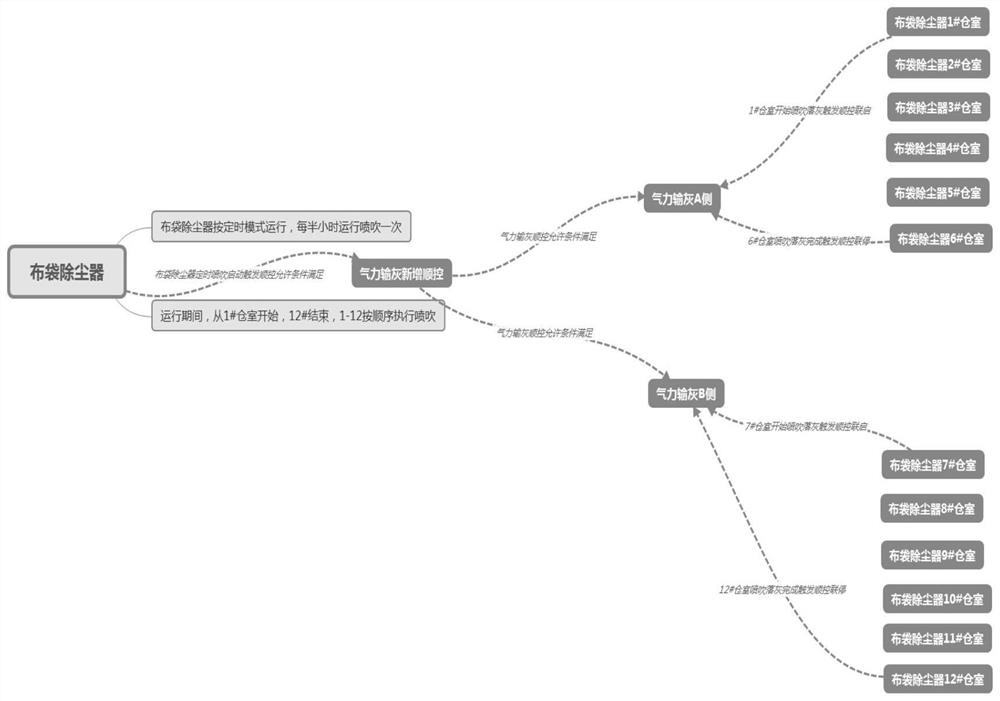

A technology of pneumatic ash conveying and control method, which is applied in separation methods, chemical instruments and methods, transportation and packaging, etc. It can solve the problems of pneumatic ash conveying and ash conveying pipeline valve wear, prolonging ash falling time and frequency of ash conveying, and large amount of ash Problems such as blocking ash transportation pipelines, etc., to achieve the effect of improving efficiency, ensuring a long cycle, and reducing the frequency of ash transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 2-5 , a specific embodiment of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

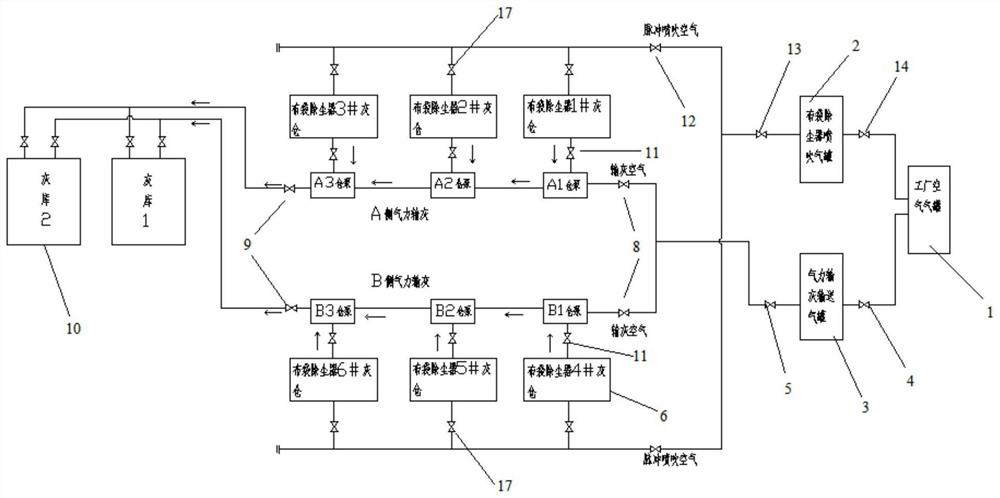

[0024] Such as image 3 with Figure 4 As shown, a pneumatic ash conveying control system provided by the present invention includes: a plurality of pneumatic ash conveying pipelines for pneumatic ash conveying, and each pneumatic ash conveying pipeline is provided with a pressurizing valve 8 and a discharge valve 9;

[0025] A plurality of blowing pipes correspond one-to-one to a plurality of pneumatic ash conveying pipes, and are used for pulse gas blowing to a plurality of ash bins 6 of the bag filter, and each blowing pipe is equipped with a manual master valve 12 for blowing;

[0026] The poppet valve 16 is set on the ash bin 6 of the bag filter, and is used to control the flue gas passing through the ash bin 6 of the bag filter. There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com