Dual-zone high back pressure variable working condition adjustable heat supply and pure condensing dual-purpose condensing steam heat exchange energy-saving device

A heat exchange, energy saving, and variable working condition technology, which is applied in the direction of household heating, heating system, space heating and ventilation, etc., can solve the problems of the unit load not being able to be carried, affecting the heating network scheduling and operation safety, and shutdown. , to achieve the effect of improving adjustability and safety, restoring external heating capacity, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

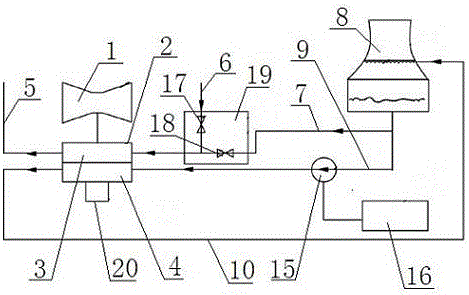

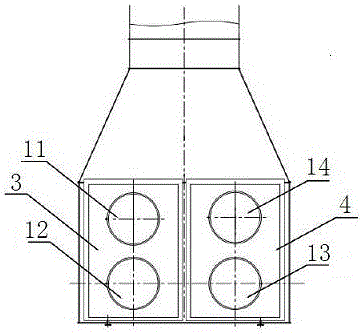

[0023] The drawings show a specific embodiment of the invention. This embodiment includes a steam turbine 1. The steam turbine 1 is connected to the upper part of a condensing heat exchange device 2 through an exhaust pipe. The condensing heat exchange device 2 is composed of mutually independent cooling zone 1 3 and cooling zone 2 4, and cooling zone 1 3 The water outlet is connected to the circulating water supply pipe 5 of the heating network, and the water inlet is connected to the circulating water return pipe 6 of the heating network. The water inlet is also connected to the cooling water tower 8 through the circulating water outlet pipe 7 of the first cooling water tower, and cooling zone 2 4 The water inlet end is connected to the cooling water tower 8 through the second cooling water tower circulating water outlet pipe 9, and the outlet end is connected to the cooling water tower 8 through the cooling water tower circulating water return pipe 10. The circulating water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com