Low-temperature vacuum evaporator used at low environment temperature

A low-temperature vacuum and low-environment technology, applied to evaporator accessories, evaporation, chemical instruments and methods, etc., can solve problems such as long time consumption and energy consumption, easy damage of compressors, and failure to start equipment, so as to avoid low load running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

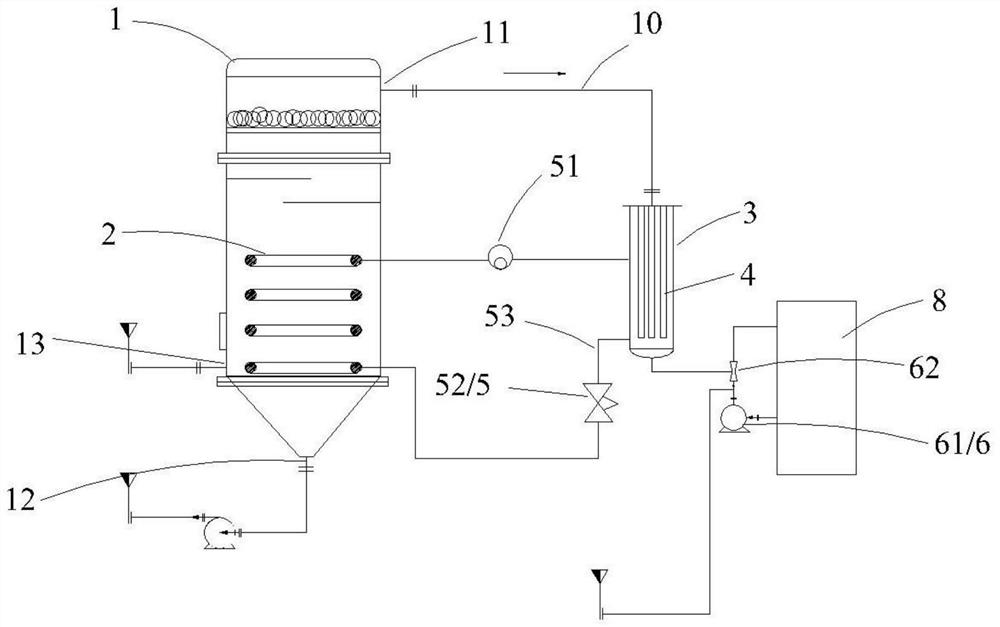

[0049] See figure 1 , the low-temperature vacuum evaporator shown in Embodiment 1 of the present invention, which includes an evaporation tank 1 for loading waste liquid, a first heat exchanger 2 for heating the waste liquid, a condensation tank 3 connected to the evaporation tank 1, A second heat exchanger 4 arranged in the condensation tank 3 and used for cooling the steam, a heat pump system 5 for providing a heat exchange medium, a decompression device 6 for vacuumizing the evaporation tank 1 and the condensation tank 3, and , a heating assembly (preheating assembly) 7 for heating the heat exchange medium entering the second heat exchanger 4 .

[0050] Specifically, the first heat exchanger 2 of this embodiment is set in the evaporation tank 1, preferably a coil heat exchanger; indeed, in other embodiments, the first heat exchanger 2 can also be other built-in The heat exchanger is, for example, a heat exchange tube, or an external heat exchanger (existing structure, not ...

Embodiment 2

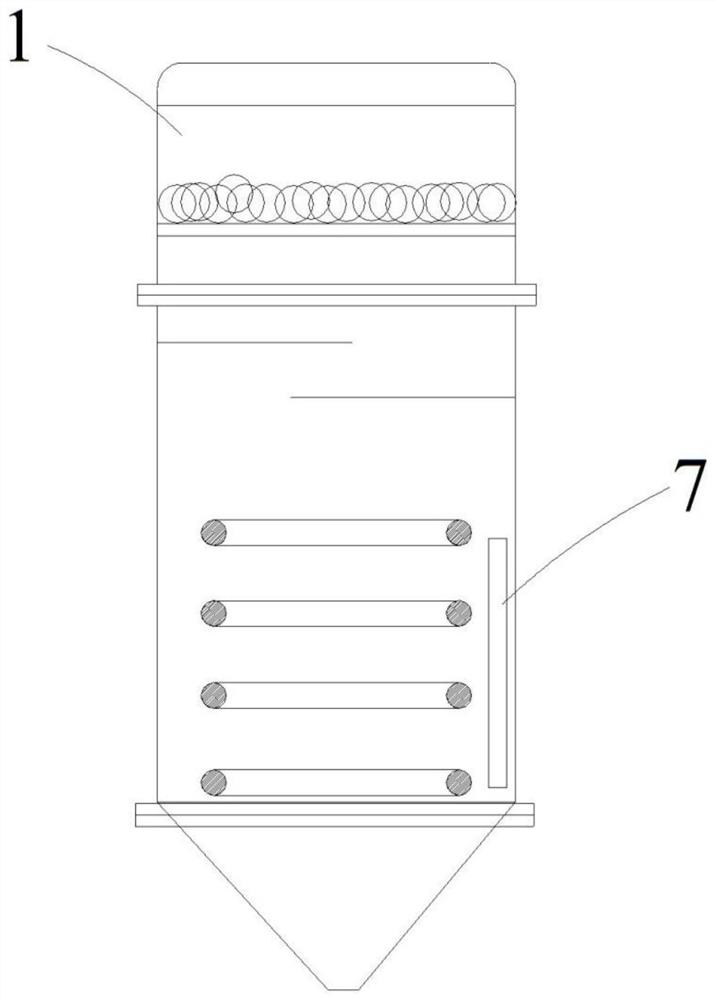

[0060] See Figure 4 and Figure 5 , the low-temperature vacuum evaporator shown in Embodiment 2 of the present invention, which includes an evaporation tank 1 for loading waste liquid, a first heat exchanger 2 for heating the waste liquid, a condensation tank 3 connected to the evaporation tank 1, A second heat exchanger 4 arranged in the condensation tank 3 and used for cooling the steam, a heat pump system 5 for providing a heat exchange medium, a decompression device 6 for vacuumizing the evaporation tank 1 and the condensation tank 3, and , a heating assembly (preheating assembly) 7 for heating the heat exchange medium entering the second heat exchanger 4 .

[0061] Specifically, the first heat exchanger 2 of this embodiment is set in the evaporation tank 1, preferably a coil heat exchanger; indeed, in other embodiments, the first heat exchanger 2 can also be other built-in The heat exchanger is, for example, a heat exchange tube, or an external heat exchanger (existing...

Embodiment 3

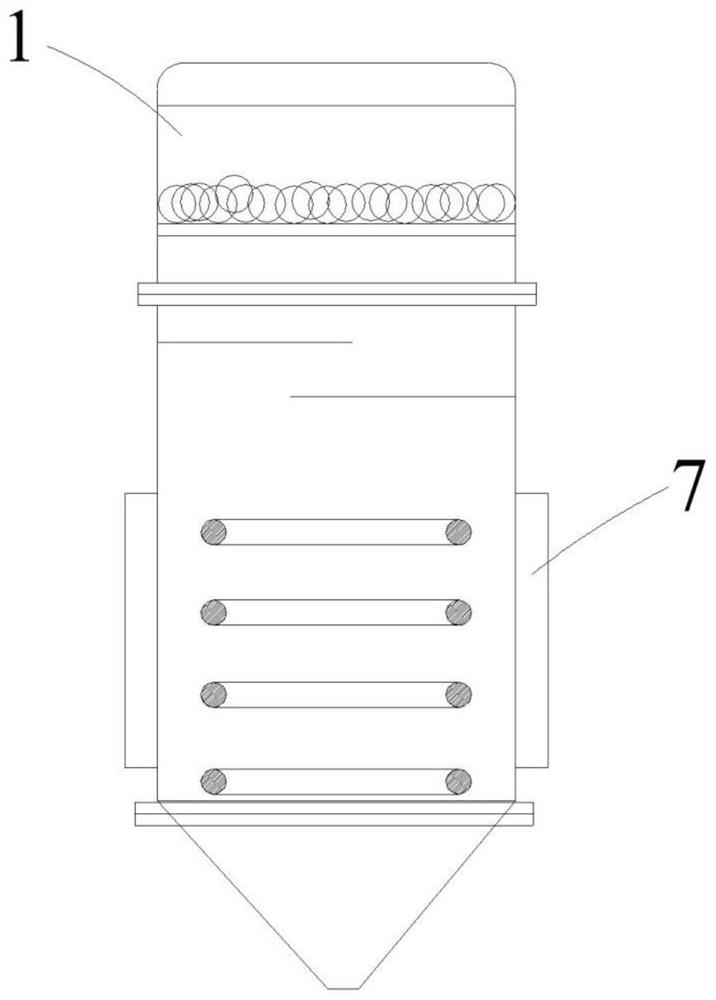

[0069] See Figure 6 to Figure 8 , the low-temperature vacuum evaporator shown in Embodiment 3 of the present invention, which includes an evaporation tank 1 for loading waste liquid, a first heat exchanger 2 for heating the waste liquid, a condensation tank 3 connected to the evaporation tank 1, A second heat exchanger 4 arranged in the condensation tank 3 and used for cooling the steam, a heat pump system 5 for providing a heat exchange medium, a decompression device 6 for vacuumizing the evaporation tank 1 and the condensation tank 3, and , a heating assembly (preheating assembly) 7 for heating the heat exchange medium entering the second heat exchanger 4 .

[0070] Specifically, the first heat exchanger 2 of this embodiment is set in the evaporation tank 1, preferably a coil heat exchanger; indeed, in other embodiments, the first heat exchanger 2 can also be other built-in The heat exchanger is, for example, a heat exchange tube, or an external heat exchanger (existing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com