Spring testing machine

A testing machine and technology to be tested, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of low testing efficiency, and achieve the effect of simplifying the structure and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

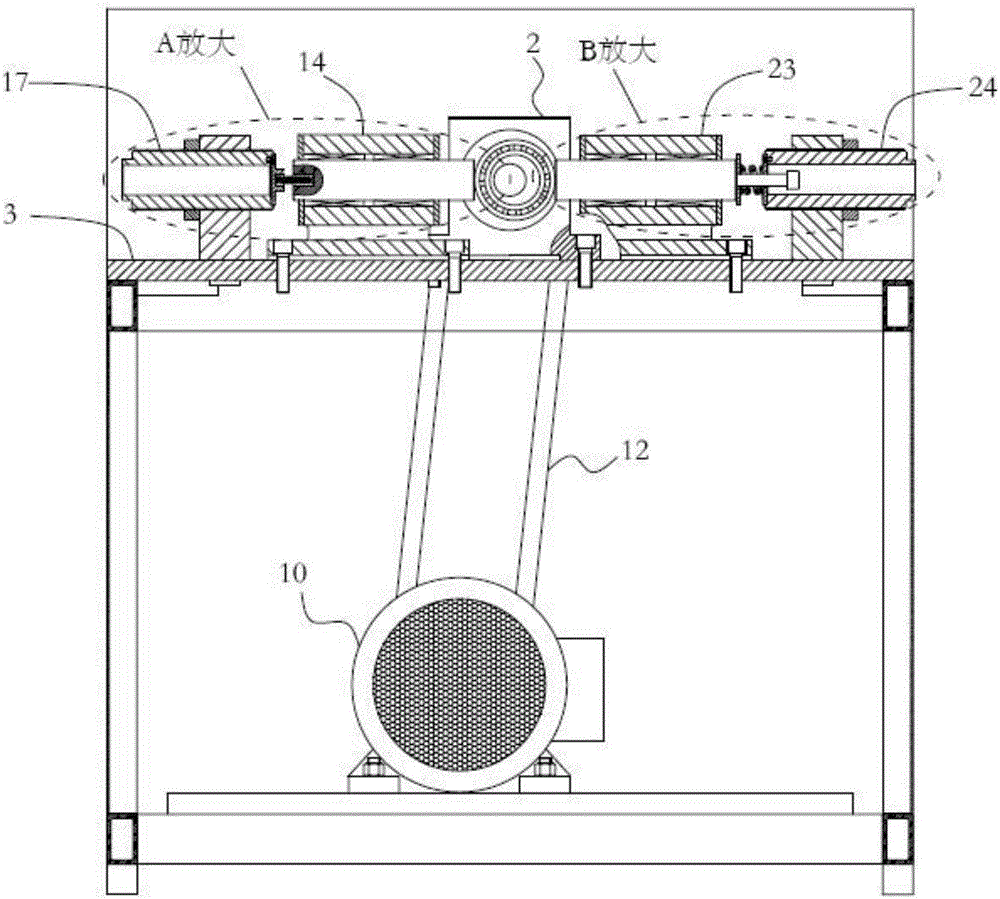

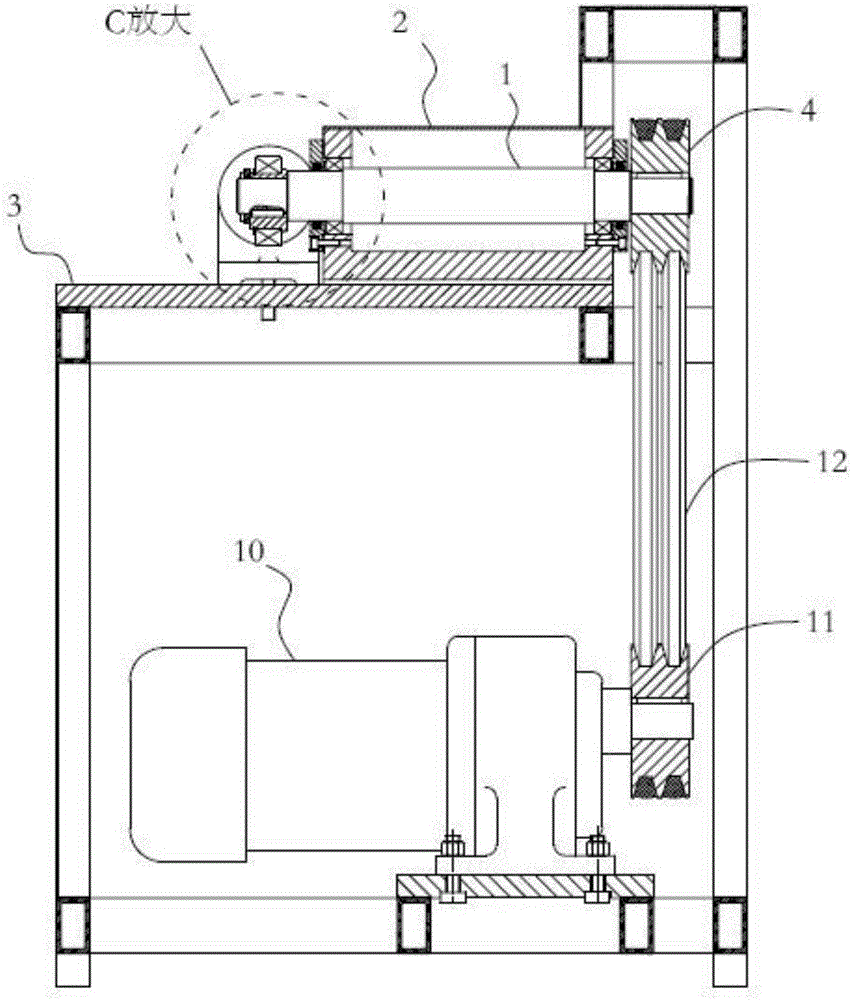

[0029] like Figure 1 to Figure 5 Shown, the spring testing machine of the present embodiment comprises:

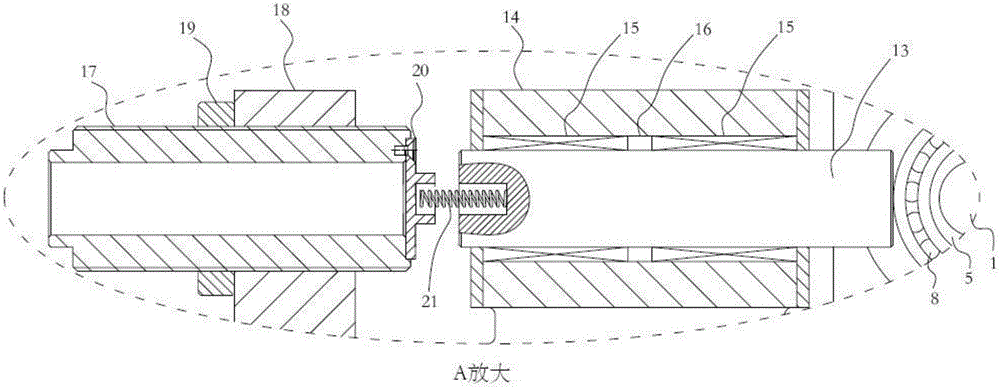

[0030] Main shaft 1, the main shaft 1 is installed in the main shaft box 2, the main shaft box 2 is placed on the table 3 of the spring testing machine, one end of the main shaft 1 is connected to the first pulley 4 with a flat key; the other end of the main shaft 1 is as Figure 5 As shown, the eccentric wheel 5 is installed on the main shaft 1 by using a flat key, and a stop ring 6 and a cotter pin 7 are installed on the outside of the eccentric wheel 5 to prevent the eccentric wheel 5 from falling off from the main shaft 1; a bearing 8 is installed on the eccentric wheel 5, and a circlip 9 is fixed Bearing 8 prevents it from falling off from eccentric wheel 5;

[0031] Motor 10, motor 10 is installed on the below of spring testing machine table top 3, and the rotating shaft of motor 10 is connected second pulley 11 by flat key, and second pulley 11 is connected with f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com