Eight-station tire high-speed durability testing machine

An endurance test, eight-station technology, applied in the direction of automobile tire testing, vehicle testing, machine/structural component testing, etc., can solve the problems of low detection efficiency and high energy consumption, and achieve high automation, convenient operation and correct Reliable results in usage and lifetime prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

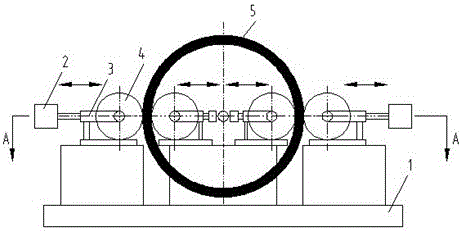

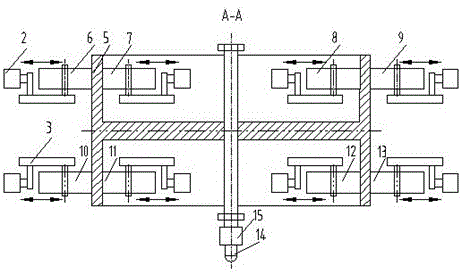

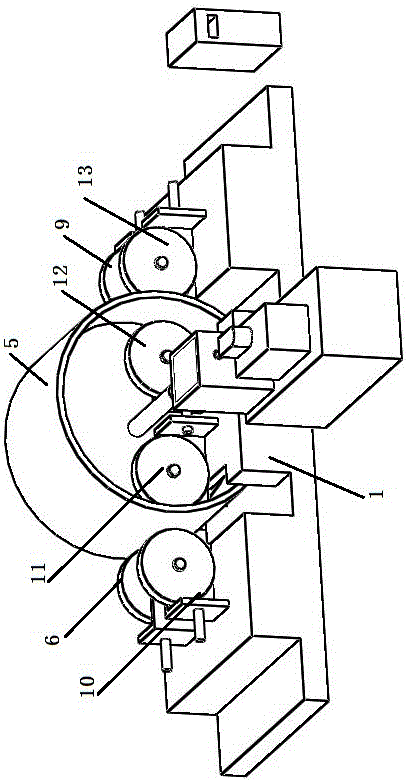

[0014] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises a frame assembly 1, a drum assembly 5, a power unit and a control system, and the inside and outside sides of the drum of the drum assembly 5 are respectively provided with a first tire station 6 and a second tire station. Station 7, third tire station 8, fourth tire station 9, fifth tire station 10, sixth tire station 11, seventh tire station 12 and eighth tire station 13, each tire station The loading device 2 and the guiding device 3 are respectively installed on the positions, and the loading device 2 exerts a load force on the guiding device 3, and each guiding device 3 is loaded with a tire rim assembly 4, and the tire rim assembly 4 is used for installing tires, guiding The device 3 moves under the pressure of the loading device 2 to press the test tire towards or away from the drum assembly 5 . The value of the applied load is transmitted to the control system through the load s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap