Cable hanging device

A cable hanger and cable machine technology, which is applied to instruments, optical fiber/cable installation, optics, etc., can solve the problems of high physical labor intensity, high operation risk, affecting construction operations, etc., so as to improve construction efficiency and reduce labor costs. , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

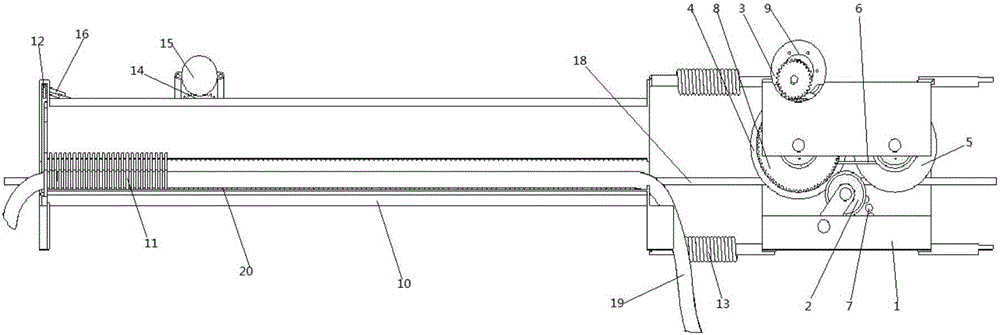

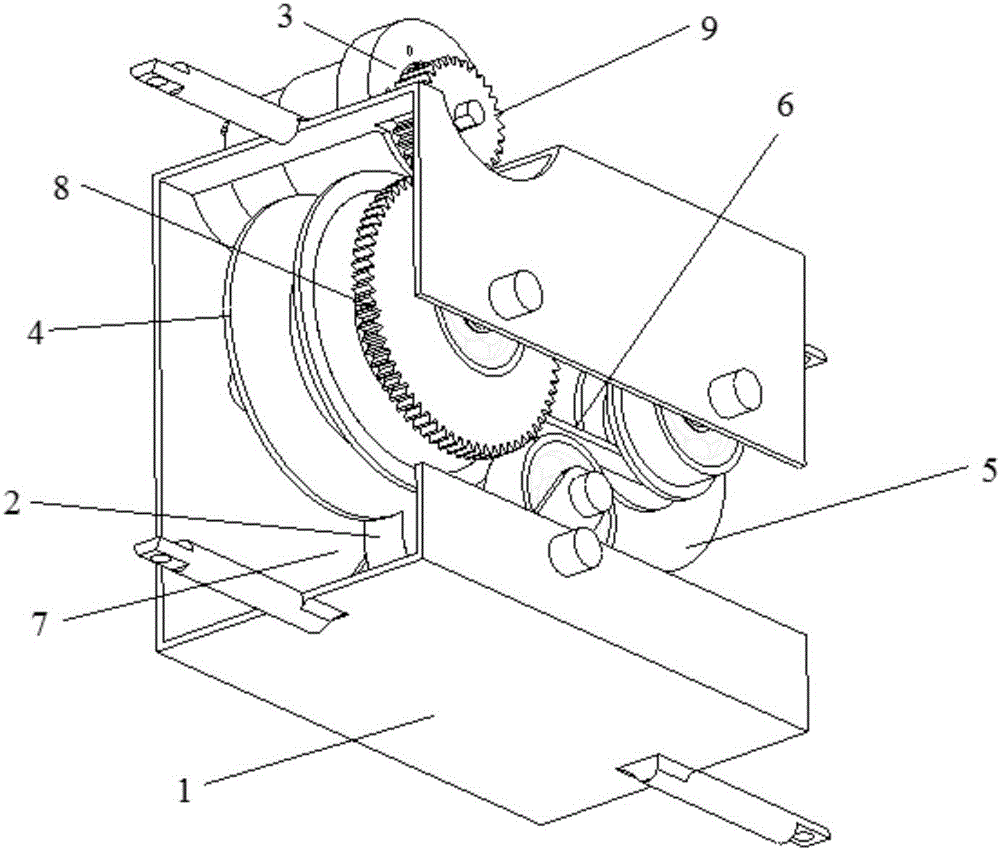

[0044] A cable hanger, see attached figure 1 And attached figure 2 , including a climbing rope assembly and a hanging cable assembly, the climbing rope assembly includes a climbing rope frame 1, and the climbing rope frame 1 is provided with a climbing rope power upper wheel, a climbing rope lower wheel 2 and a climbing rope power motor 3,

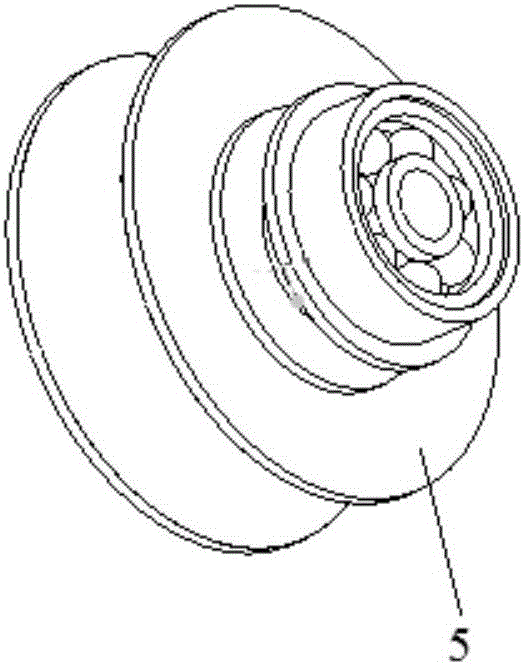

[0045] The climbing rope power upper wheel comprises a climbing rope left power wheel 4 and a climbing rope right power wheel 5;

[0046] A belt 6 is connected between the climbing rope left power wheel 4 and the climbing rope right power wheel 5;

[0047] A steel strand 18 is sandwiched between the climbing rope left power wheel 4, the climbing rope right power wheel 5 and the climbing rope lower wheel 2;

[0048]The lower wheel 2 of the climbing rope is connected with the pressure swing arm 7 of the lower wheel of the climbing rope; the pressure swing arm 7 of the lower wheel of the climbing rope controls the lower wheel 2 of the clim...

Embodiment 2

[0056] A kind of cable hanger, similar to embodiment 1, the difference is, see attached Figure 7 , the toggle piece 17 is arranged as three cylinders protruding from the hanging cable power gear 14, and the included angle between adjacent cylinders is 120°. In this way, the hanging cable power gear 14 can drive the hanging cable swing arm 16 to move more efficiently through the toggle member 17 .

Embodiment 3

[0058] A cable hanging device, similar to Embodiment 2, the difference is that the hanging cable power motor 15 is connected with the distance measuring and angle measuring device through the control unit, and the control unit is based on the climbing rope assembly measured by the distance measuring and angle measuring device The running distance controls the opening and running of the hanging cable power motor 15, and the control unit controls the closing and stopping of the hanging cable power motor 15 according to the angle of rotation of the climbing rope gear 8 measured by the ranging and angle measuring device; When the device measures the angle of rotation of the climbing rope gear 8 to be 120 °, the control hanging cable power motor 15 is closed and stopped. In this way, after the climbing rope assembly runs to the preset distance along the steel strand 18, the hanging cable assembly ejects the hook 11 to hang the cable; when the number of hooks 11 in the hanging cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com