Copper-sheathed fireproof cable

A copper sheath and cable technology, which is applied in the field of power cables, can solve problems such as open circuit, multiple joints, and the influence of cable manufacturing length, so as to reduce space occupation, ensure reliability, and prevent external magnetic fields from interfering with itself. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

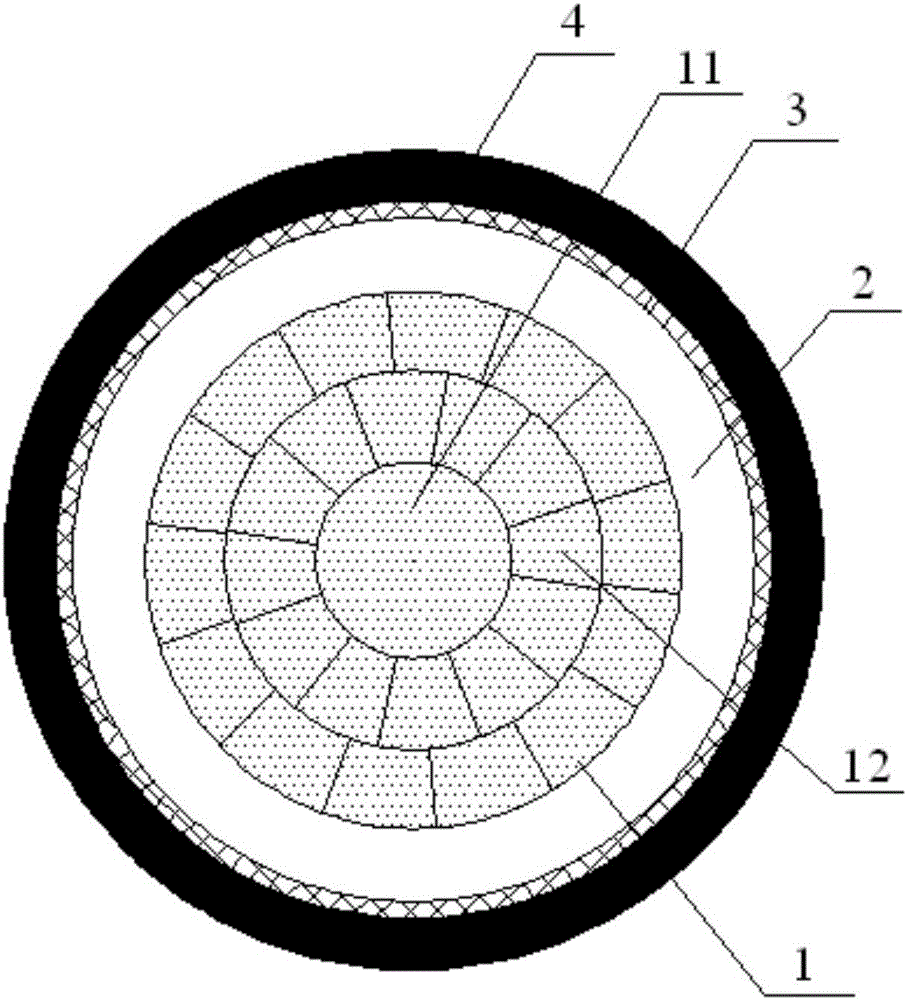

[0015] A copper-sheathed fire-resistant cable, the structure of which is as follows figure 1 As shown, it includes a conductor core 1 in the center, and the outer part of the conductor core 1 is wrapped with a mica tape layer 3 to protect the conductor core and prevent the conductor core from oxidizing; a silica gel insulating layer is arranged between the mica tape layer 3 and the conductor core 1 2. The mica tape layer 3 is provided with a longitudinal seam welded copper sheath layer 4 .

[0016] The conductor core 1 is formed by twisting multiple conductors, including at least one central conductor 11 located in the center with a circular conductor cross-section, and at least one layer of special-shaped conductors whose cross-sections can be closely arranged after stirring are stranded on the outside of the center conductor. Floor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com