High Strength Roller Tiller

A high-strength tiller technology, which is applied in the field of tiller and high-strength roller tiller, can solve the problems of ineffective tillage, poor comprehensive strength, and easy soil hardening, etc. Difficulty of milling, improvement of hardness, effect of finely crushed soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

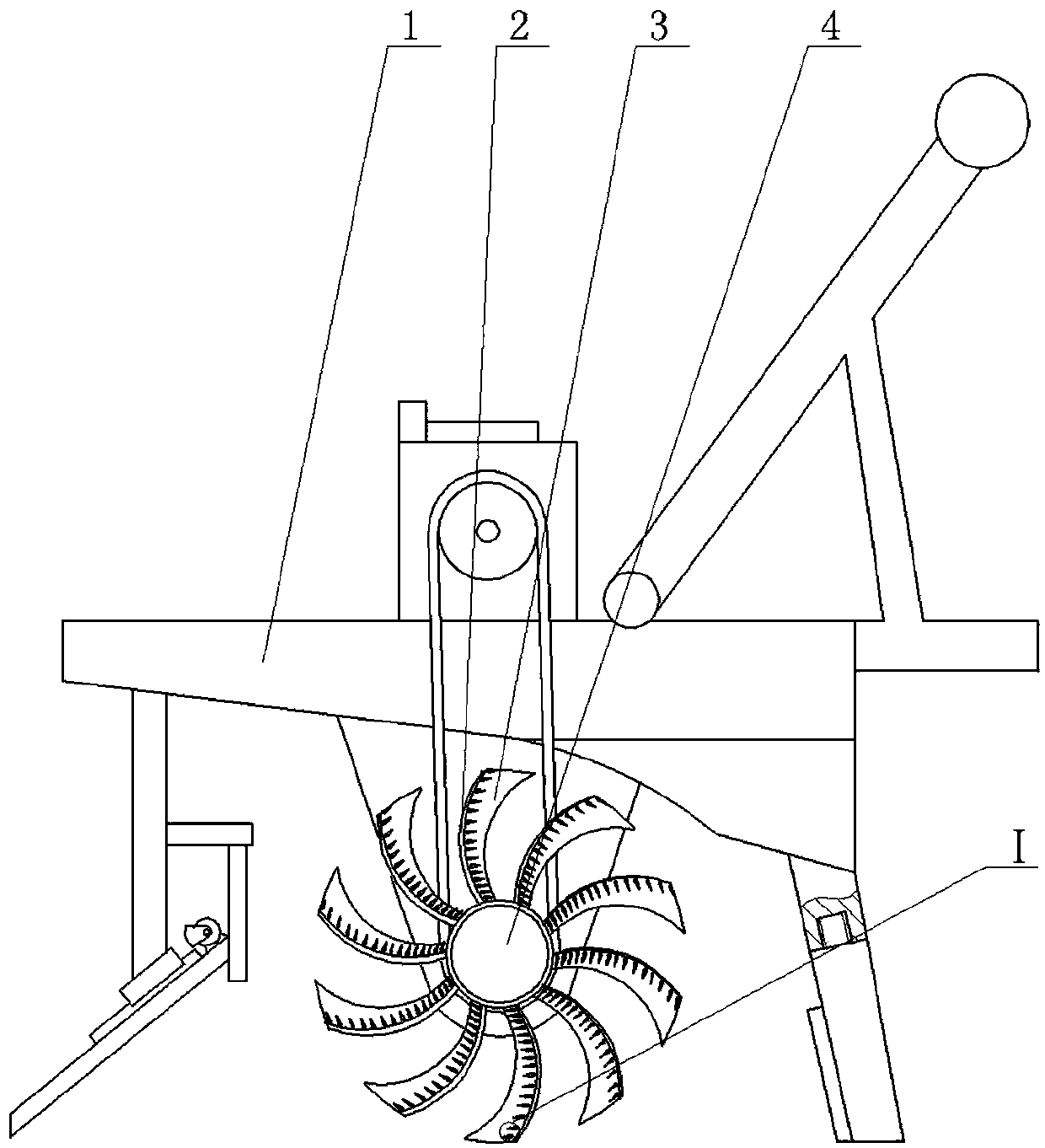

[0034] Embodiment: a kind of high-strength roller tiller

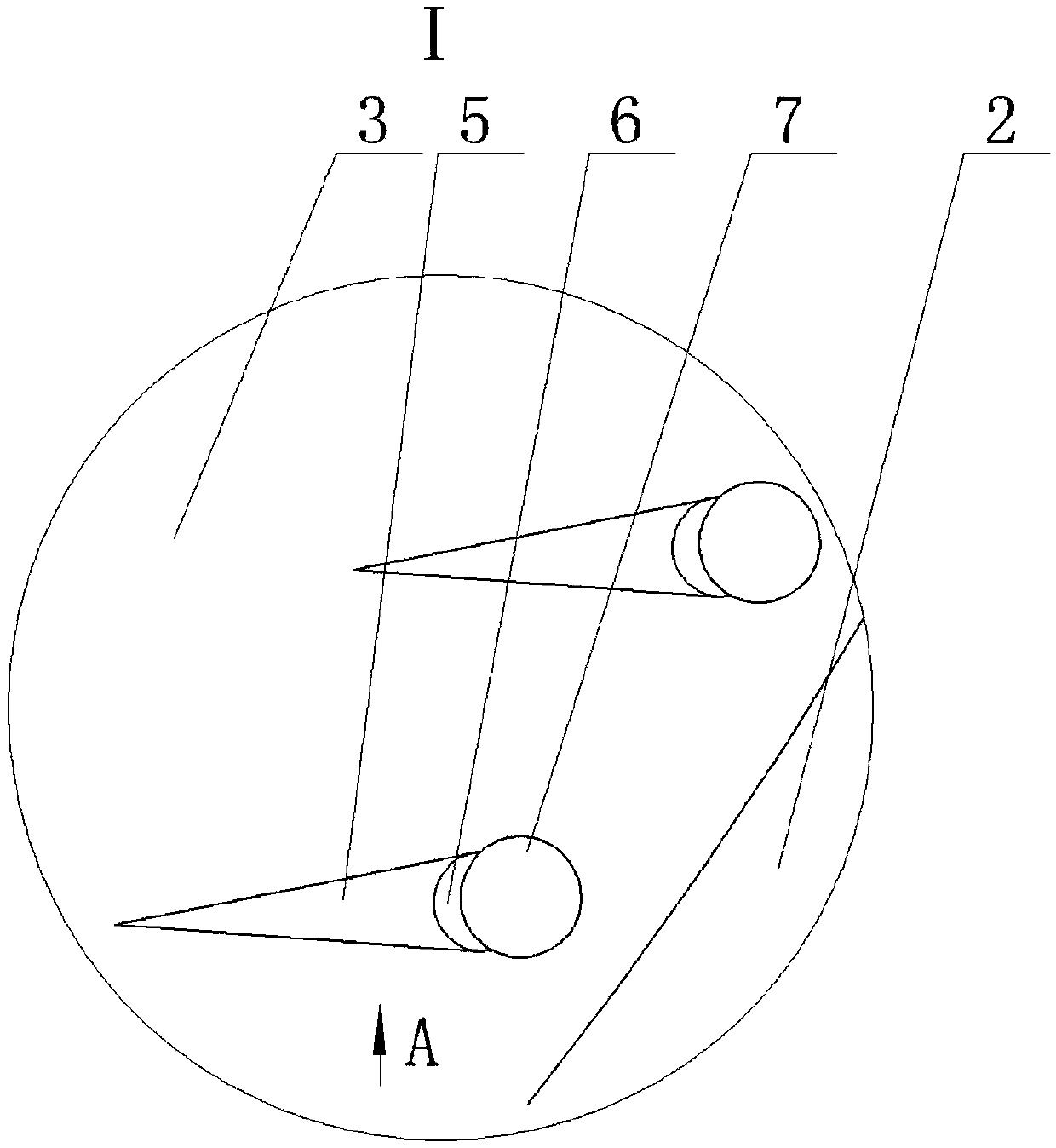

[0035] refer to figure 1 - image 3 , the present embodiment includes a rotary tiller body 1, a rotary tiller wheel 4 is installed on the bottom of the rotary tiller body 1, and several cutter bodies 3 are installed on the side circumference of the rotary tiller wheel 4.

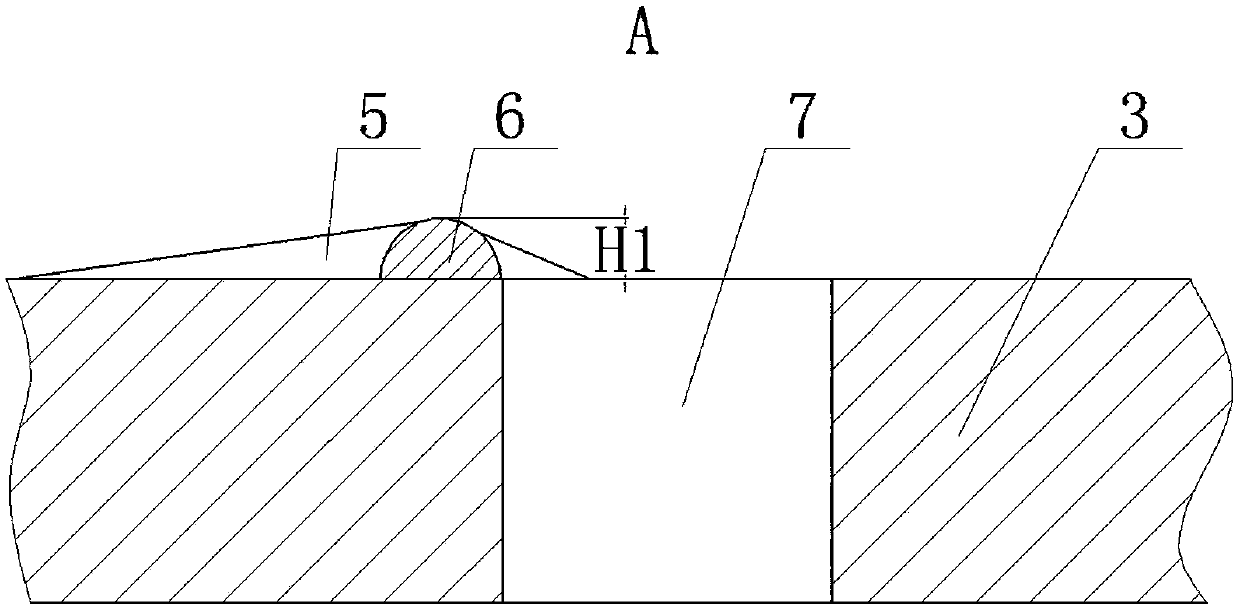

[0036] One side of cutter body 3 is provided with blade 2, and blade 2 is positioned at the side that contacts with soil preferentially when cutter body 3 rotates, and several through holes 7 are offered on cutter body 3, and through hole 7 is positioned at the side of blade 2, and cutter body 3 Ridge 5 and blocking block 6 are arranged on both sides of , and blocking block 6 is positioned at the side of through hole 7, and rib 5 is positioned at the side of blocking block 6, and the height of blocking block 6 is H1, and H1=1 centimetre, and convex rib 5 The height is less than the height of the blocking block 6, and the aperture of the through hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com