Firing method for glazed ceramic teapot

A production method and teapot technology, which are applied to furnaces, lighting and heating equipment, stove components, etc., can solve the problems of the overall unattractiveness of the pot body and the wear of the table top, and achieve the effects of improving the overall ornamental quality, improving the quality and reducing the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

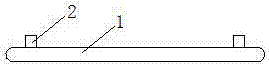

[0015] The firing method of the glazed ceramic teapot of the present invention is to dip the teapot body in glaze water and place it upside down on the support base, and the support base and the inner edge of the teapot spout are bonded together by an adhesive After firing, knock the supporting seat to make the supporting seat fall off. The bottom edge of the teapot produced in this way also has a complete glaze surface, and there is no accumulation of glaze water on the bottom edge. Get a teapot with a full glaze.

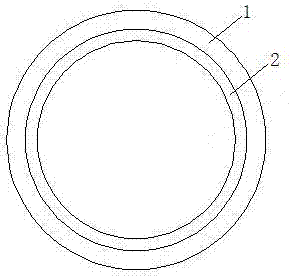

[0016] refer to figure 1 , the supporting seat of the ceramic teapot comprises a circular seat body, the top of the seat body is provided with a ring-shaped support platform near the edge, and a hole is opened on the seat body.

[0017] After soaking the teapot in glaze water, put it upside down on the support base, and then fire the support base and the inner edge of the teapot spout with adhesive, so as to prevent the glaze water from flowing to the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com