Semiconductor device

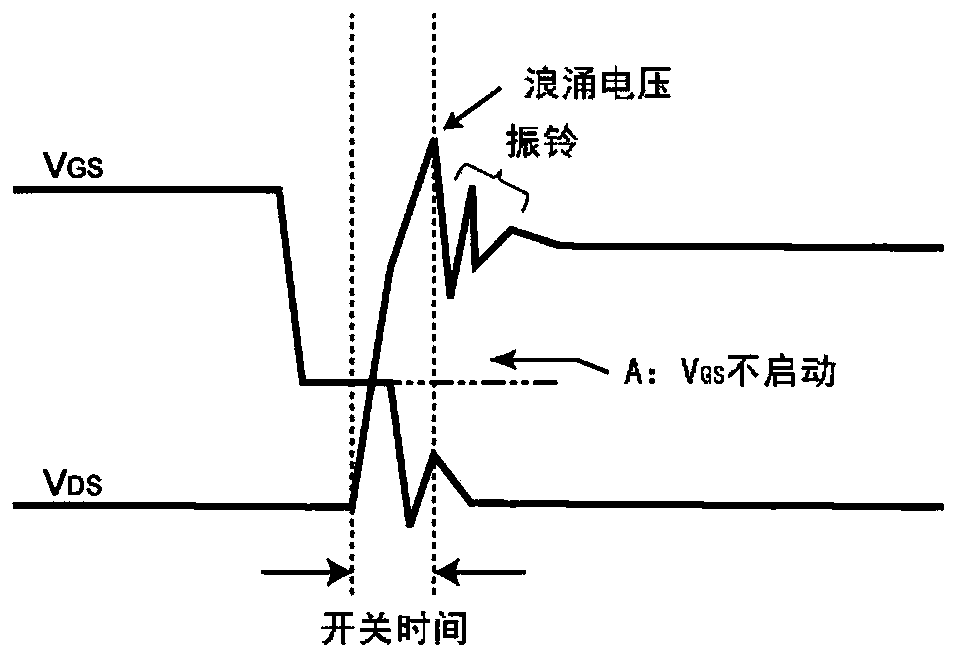

A semiconductor and substrate technology, applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as reducing surge voltage, slowing down switching speed, and operating errors, so as to prevent the increase of switching losses, ease potential changes, and suppress The effect of running errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

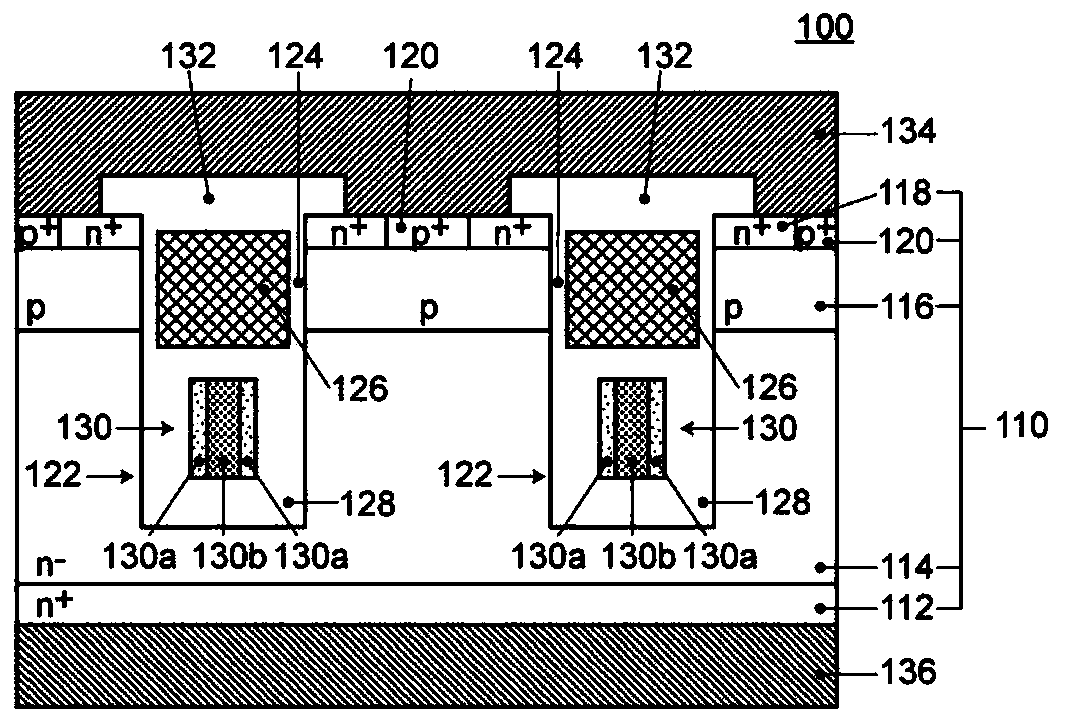

[0046] 1. Semiconductor device

[0047] The semiconductor device 100 involved in Embodiment 1, as shown in FIG. Adjacent n-type drift region (first conductivity type drift region) 114, p-type base region (second conductivity type base region) 116 adjacent to n-type drift region 114, and p-type The n+ type source region (first conductivity type source region) 118 adjacent to the base region 116; the trench 122 is formed in the semiconductor substrate 110 and has a groove bottom adjacent to the n-type drift region 114, And the sidewall adjacent to the p-type base region 116 and the n-type drift region 114, and is formed in a stripe shape when viewed from the plane; the gate electrode 126 is arranged in the trench 122, and, on the sidewall A part is opposite to the p-type base region 116 through the gate insulating film 124; the shielding electrode 130 is arranged in the trench 122, and is located between the gate electrode 126 and the bottom of the trench 122; the electrical in...

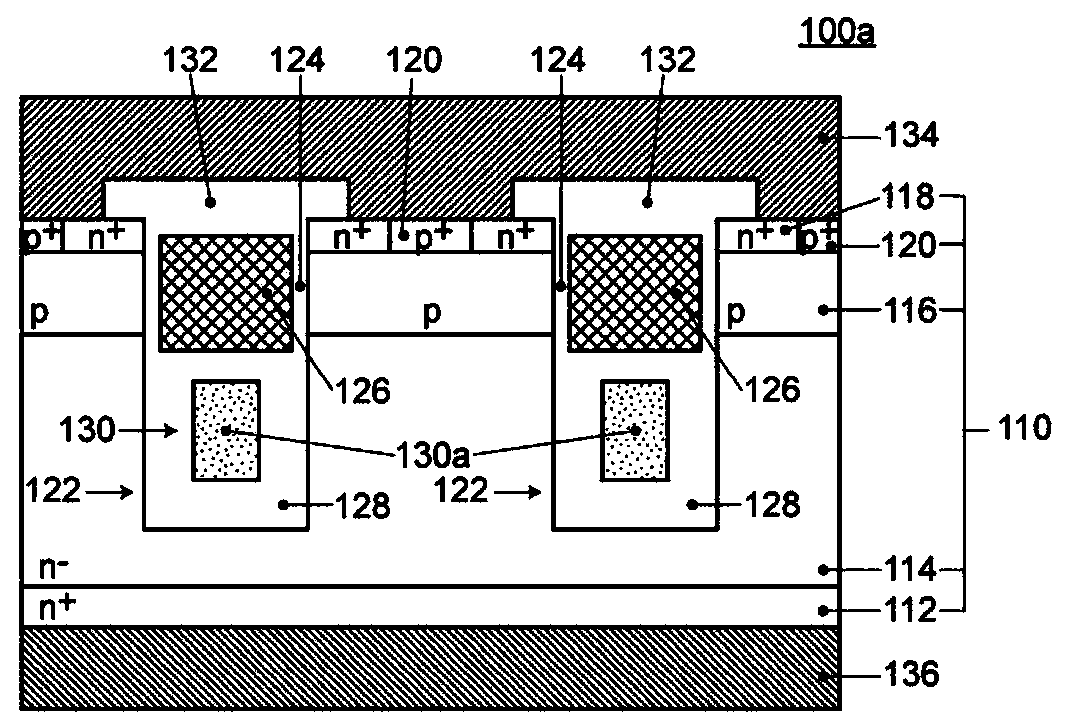

Embodiment approach 2

[0090] The semiconductor device 101 according to the second embodiment basically has the same configuration as the semiconductor device 100 according to the first embodiment, but differs from the semiconductor device 100 according to the first embodiment in the configuration of the shield electrode. That is, if Figure 9 As shown, in the semiconductor device 101 according to Embodiment 2, the high-resistance region 130a and the low-resistance region 130b are made of different materials, and the resistivity of the material constituting the low-resistance region 130b is lower than that of the material constituting the high-resistance region 130a. The resistivity of the material (see Figure 9 ).

[0091] As a material constituting the high-resistance region 130a, for example, high-resistance polysilicon formed by CVD can be used. In addition, as a material constituting the low-resistance region 130b, for example, a metal with a high melting point (eg, W, Mo, Ta, Nb, etc.) and ...

Embodiment approach 3

[0095] The semiconductor device 102 according to the third embodiment basically has the same configuration as the semiconductor device 100 according to the first embodiment, but differs from the semiconductor device 100 according to the first embodiment in the configuration of the shield electrode. That is, if Figure 10 As shown, in the semiconductor device 102 according to the third embodiment, the high-resistance region 130 a and the low-resistance region 130 b are located at positions separated from each other via the electrically insulating region 128 .

[0096] The interval between the high-resistance region 130a and the low-resistance region 130b can be appropriately set, for example, it can be set to 0.5 μm.

[0097] In this way, although the semiconductor device 102 according to the third embodiment is different from the semiconductor device 100 according to the first embodiment in the structure of the shield electrode, it has The high-resistance region 130a and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com