Rail driving type pot seedling transplanting machine tail end executing device

An end-effector, drive-type technology, applied in transplanting machinery, planting methods, applications, etc., can solve the problems that the linkage mechanism cannot maintain a stable clamping angle, the linkage mechanism is deformed, and the torque is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

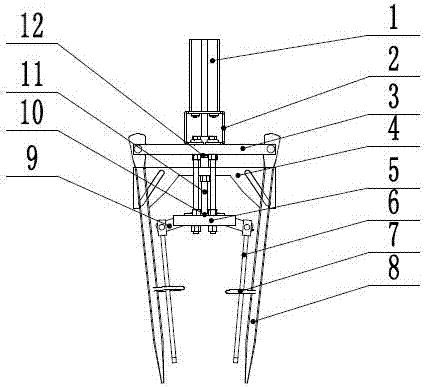

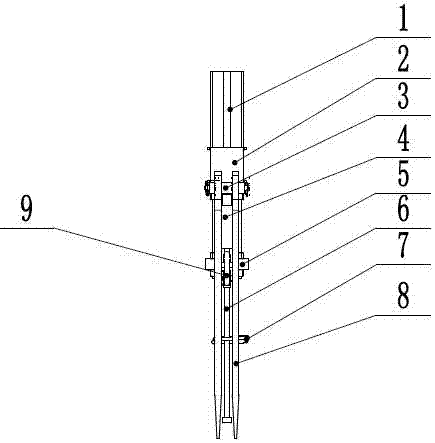

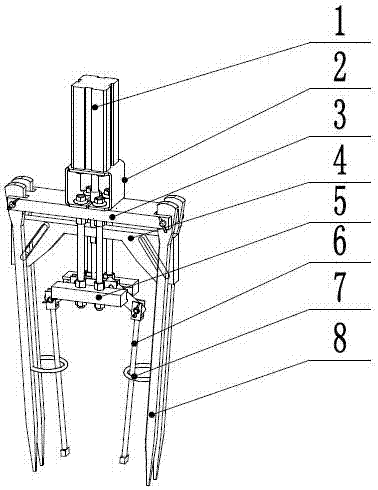

[0016] The cylinder (1) is fixed on the upper surface of the main support plate (3) through the cylinder mounting frame (2), and the push rod of the cylinder (1) passes through the center hole of the cylinder mounting frame (2) to connect with the drive connecting rod; the main support plate (3) Two seedling pushing track blocks (5) are fixed directly below them through four long screw rods, and four seedling taking needles (8) are connected with pin shafts at the left and right ends; the driving connecting rod (12) passes through the main support plate (3 ) center hole is connected with the control connecting rod (11), the track plate (4) is fixed with the seedling pushing control block (10) through the control connecting rod (11), and the seedling pushing control block (10) and the seedling pushing control rod (9) are riveted connection, the sliding table part of the seedling pushing control rod (9) is put into the track of the seedling pushing track block (5), and the other ...

Embodiment 2

[0018] Seedling clamping action: the push rod of the cylinder (1) drives the drive connecting rod (12) to move down, pushing the track plate (4) to move down, and the track of the track plate (4) acts on the slide table of the seedling needle (8) to make the seedling needle ( 8) The angle changes to achieve clamping, and at the same time the seedling pushing control block (10) moves down, the sliding table of the seedling pushing control rod (9) slides in the seedling pushing track block (5), the seedling pushing control rod (9) moves, and the seedling pushing The needle (6) moves upwards in the restricting ring (7) for pushing seedlings, and moves outwards to the outside to prevent the pushing needles (6) from affecting the potted seedling plants.

Embodiment 3

[0020] Seedling release action: the cylinder (1) push rod is lifted up, the seedling taking needle (8) is lifted up in the track of the track plate (4), and the angle deflection is realized to release the seedlings. At this time, the seedling pushing needle (6) is greatly lowered Move to the seedling clamping part of the corresponding seedling-taking needle (8) to realize the seedling pushing action and prevent the seedling-taking needle from hanging the seedlings. The swing angle of the seedling-taking needle (8) in the seedling-releasing action is relatively large, which has exceeded the initial angle of seedling-taking in the ready state. After the seedlings are released, the push rod of the cylinder (1) needs to be moved down to return to the ready state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com