Stab-resistant body armor based on carbon fiber plate splicing block

A technology of carbon fiber board and stab-resistant clothing, applied in the field of stab-resistant clothing, can solve the problems of heavy weight, inflexible wearing, and high manufacturing cost of stab-resistant clothing, achieve good comfort and flexibility, simple and controllable processing process, and easy to wear good comfort effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A stab-resistant clothing based on carbon fiber plate splicing blocks provided in Embodiment 1 of the present invention includes a stab-resistant jacket and two stab-resistant layers 1, and the stab-resistant jacket is a vest structure with a stab-resistant layer accommodation cavity. The two stab-resistant layers 1 are respectively arranged on the front panel and the rear panel of the stab-resistant jacket.

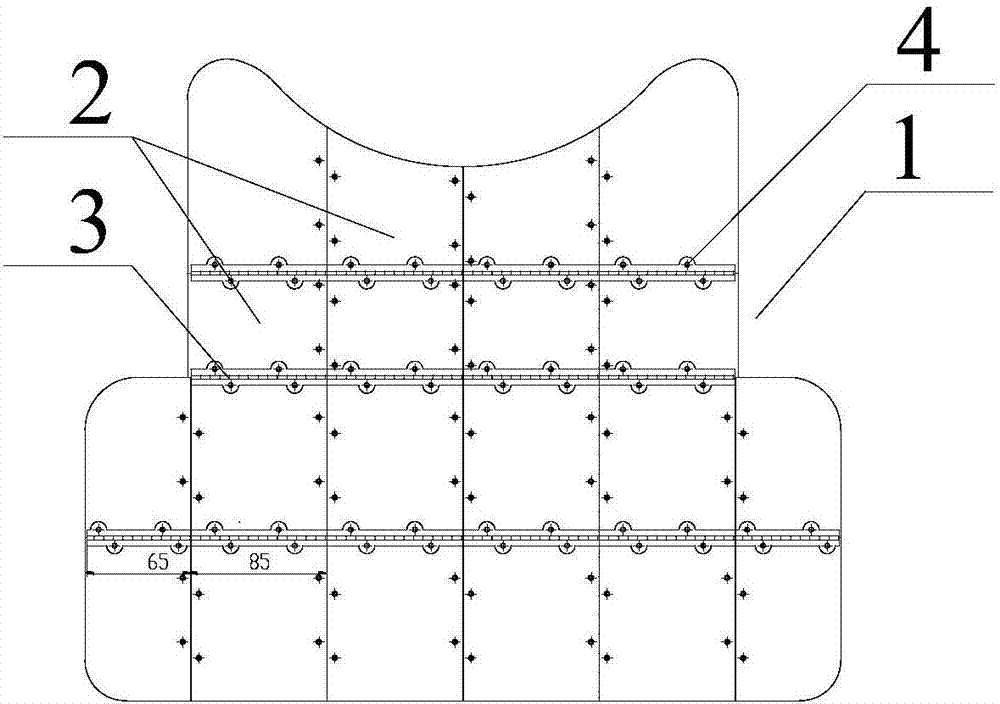

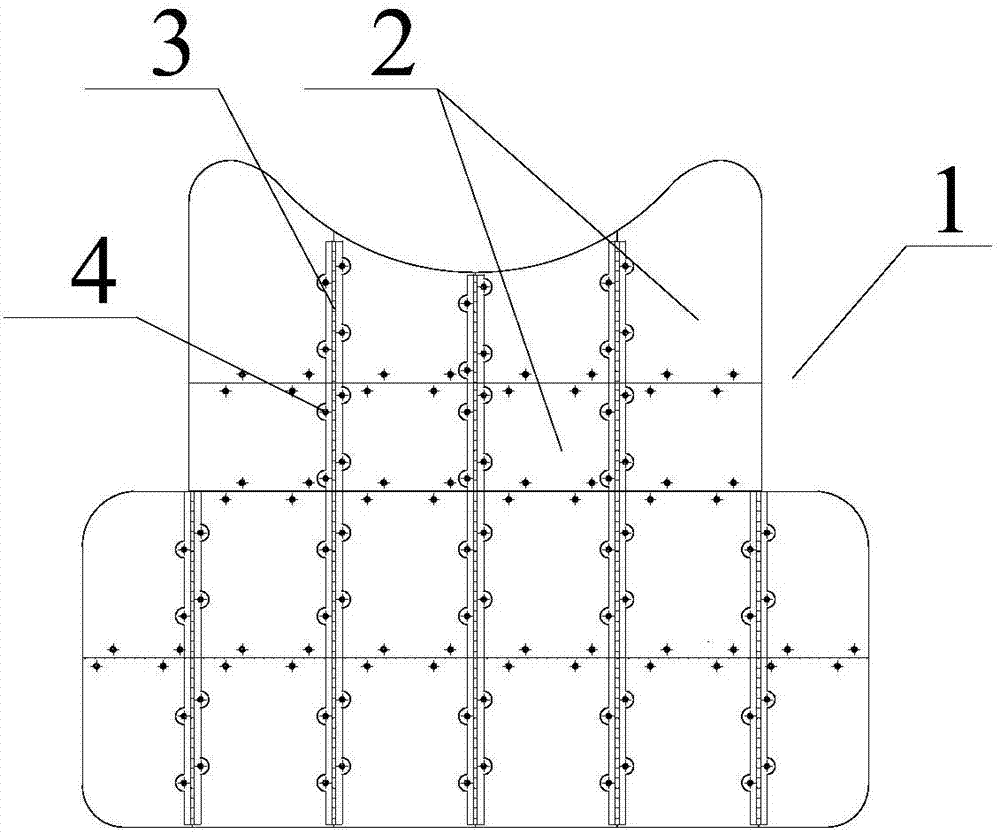

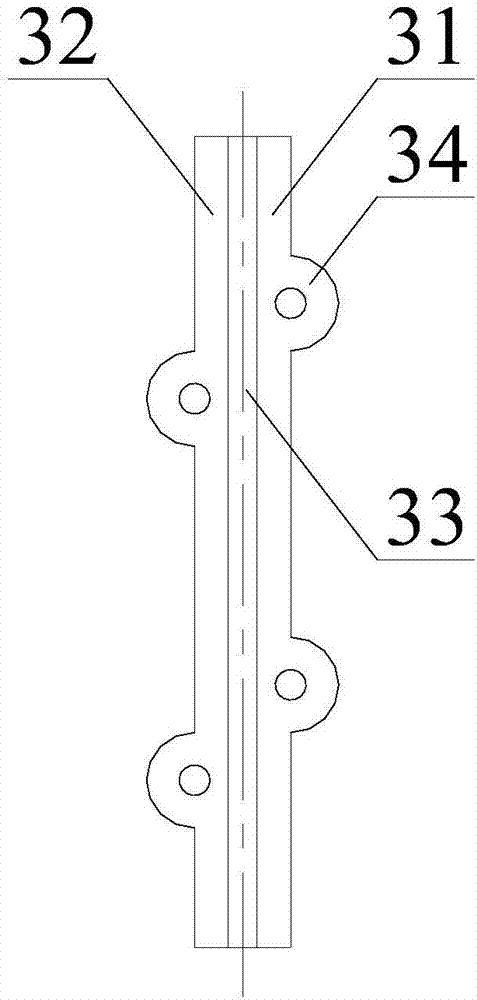

[0029] Such as figure 1 As shown, the stab-proof layer 1 has a "convex"-shaped structure as a whole, and the six corners of the middle part of the upper end, the shoulder and the waist are all arc-shaped, and specifically include a plurality of stab-proof layers that are made of carbon fiber boards and processed by CNC. slice 2.

[0030] The stab-proof sheet 2 of the stab-proof layer 1 has a horizontal and transverse length of 85mm, and the vertical and longitudinal dimensions of the stab-proof sheet 2 from top to bottom are 100mm, 65mm, 100mm and 100mm successiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com