An online production process of 3D embossed diapers

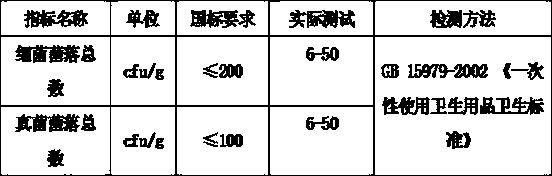

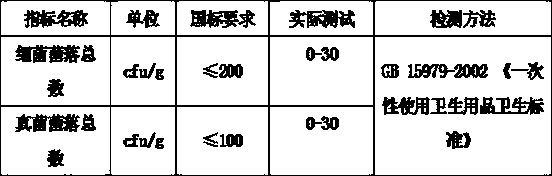

A production process and embossed paper technology, which is applied in the field of sanitary products, can solve the problems of increasing raw materials and increasing microbial indicators, and achieve the effects of reducing irritation, reducing skin friction, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

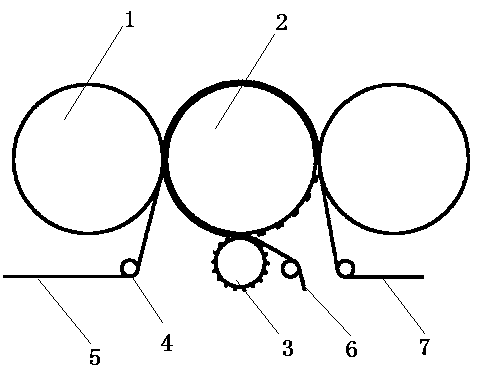

Image

Examples

Embodiment

[0030] Embodiment: 1. Forming of the absorbent core: put wood pulp into a pulverizer and pulverize it into fibrous fluff pulp, shape the fluff pulp into the cotton core in the absorbent core layer in the product, and add the polymer material evenly through the polymer adder Into the cotton core of the product, the cotton core is conveyed through the vacuum box device, and the toilet paper roll is unrolled at the same time, the cotton core is attached to the toilet paper and compacted, and the cotton core is wrapped with toilet paper through the vacuum box and folding tool, and passed The pinch roller compacts the wrapped cotton core to form an absorbent core;

[0031] 2. The absorbent core is subjected to grid-pressing treatment;

[0032] 3. Cut the absorbent core into the specified shape according to the product drawing;

[0033] 4. Compounding of the bottom non-woven fabric: adding PE film and non-woven fabric to form the bottom non-woven fabric;

[0034] 5. The 100% natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com