Turnover type oblique plate precipitation tank

An inclined plate sedimentation and flipping technology, which is applied in the direction of sedimentation separation, control of the inclination of sedimentation equipment, settling tank, etc., can solve the problems of inconvenient sludge discharge and sludge deposition, and achieve the effect of facilitating sludge discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

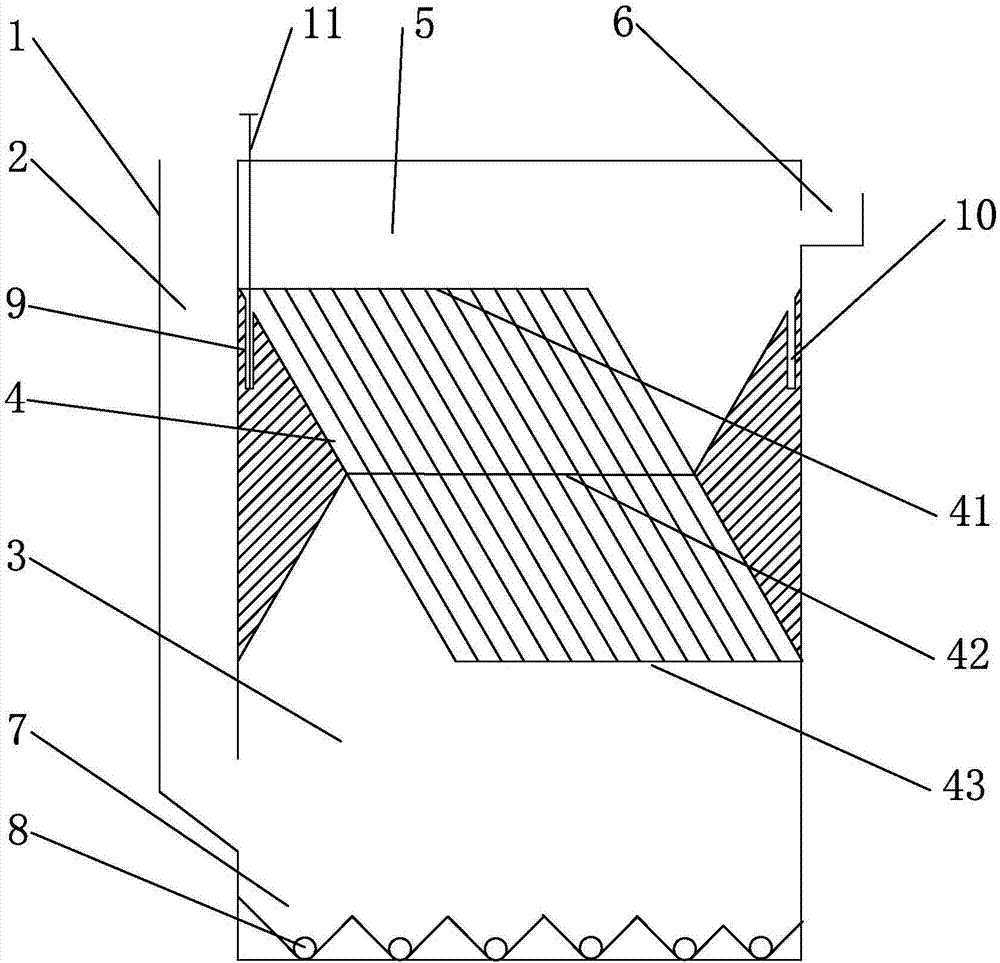

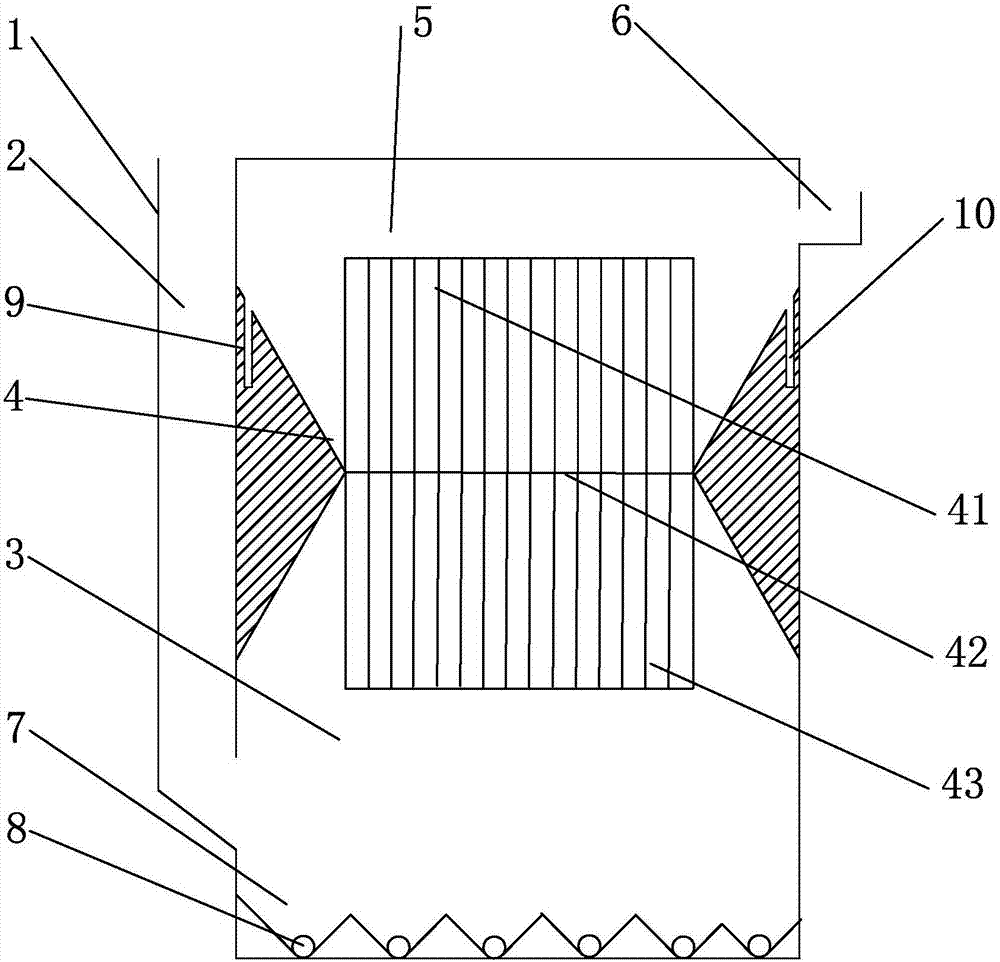

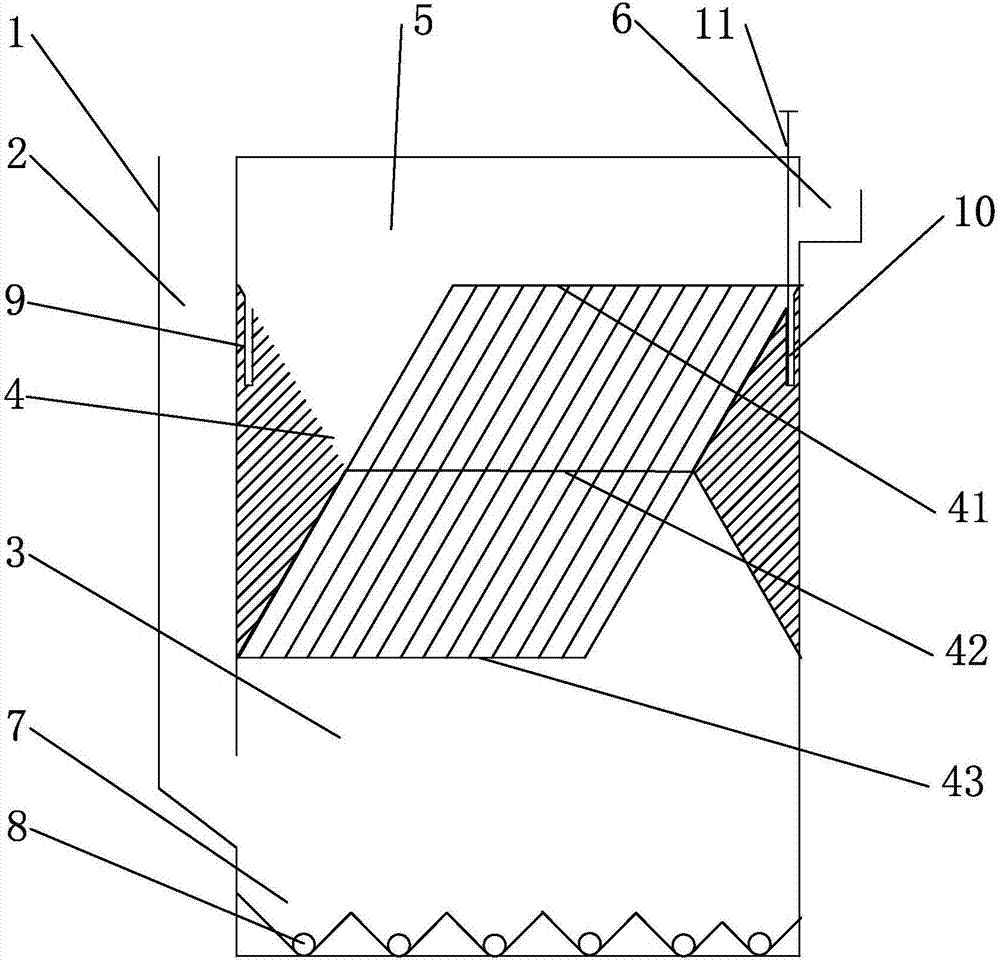

[0015] In order to solve the problems of sludge deposition and inconvenient sludge discharge in the existing inclined plate sedimentation tank, the present invention proposes a reversible inclined plate sedimentation tank.

[0016] Including shell 1, water inlet channel 2, sedimentation area 3, inclined plate 4, clear water area 5, water outlet 6, mud bucket 7, mud discharge pipe 8, left fixing hole 9, right fixing hole 10, and fixing spike 11.

[0017] The sewage enters the sedimentation zone 3 of the sedimentation tank through the water inlet channel 2, and through the sedimentation of the inclined plate 4, the clean water enters the clean water zone 5, and then is discharged from the water outlet tank 6; the settled sludge falls into the sedimentation zone 3, and then falls into the mud Bucket 7, after the mud bucket 7 is full, the sludge is discharged by the mud discharge pipe 8.

[0018] There are multiple inclined plates 4 , and each inclined plate 4 is connected by an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com