Biological treatment device for oily sewage in oil field

A sewage biological treatment, oil field technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to zonally and flexibly control, to reduce pool wall leakage, reduce The effect of on-site operation time and cost saving of demolition racks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

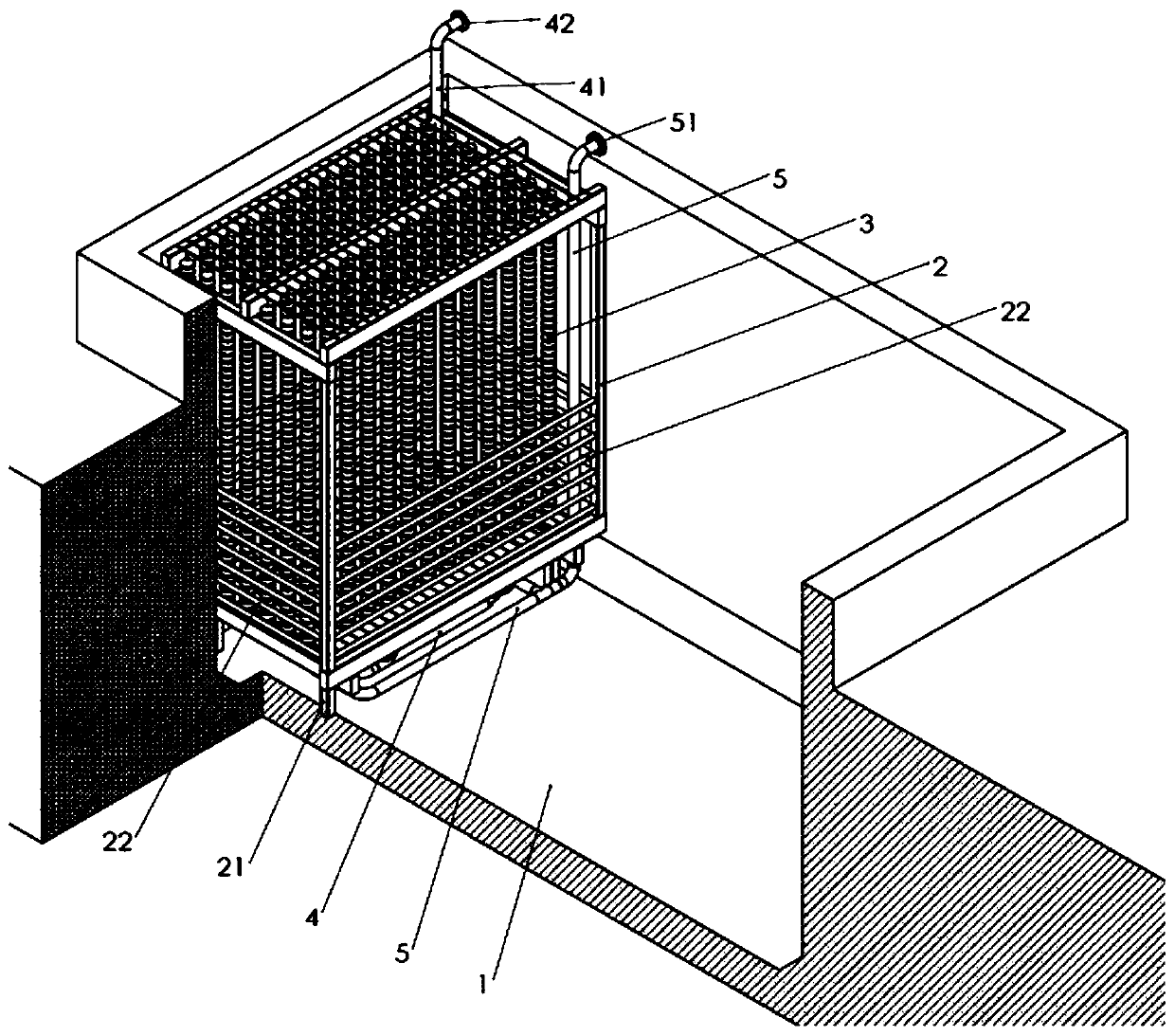

[0015] The biological treatment device for oily sewage in the oil field includes a biological pool body 1. The treatment device divides the entire biological pool body 1 into several rectangular partitions, and each partition has a top surface with the same shape and size as the partition and a height slightly lower than the normal biological pool. The movable filler frame 2 on the working liquid level, the movable filler frame 2 is a cubic frame, and the movable filler frame 2 is covered with the entire biological pool body 1. When some parts of the biological pool fail and need to be repaired or replaced, only the parts involved in the operation need to be hoisted. Filler frame, even needn't stop production; The lower part horizontal direction of four sides of movable filler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com