Wedge-shaped piece side cutting mold

A wedge shape and mold technology, applied in the field of wedge side cutting molds, can solve the problems of single cutting form, inflexibility of wedge pieces, frequent replacement of cutting molds, etc., and achieve the effect of ingenious conception and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

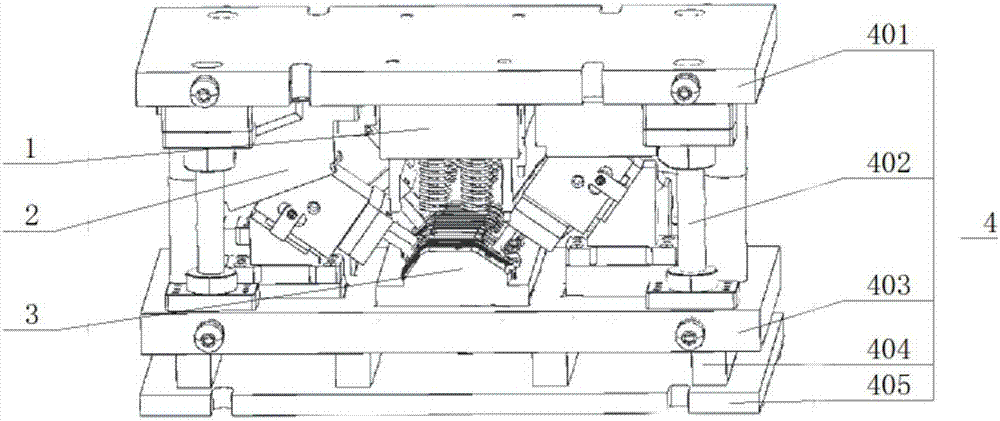

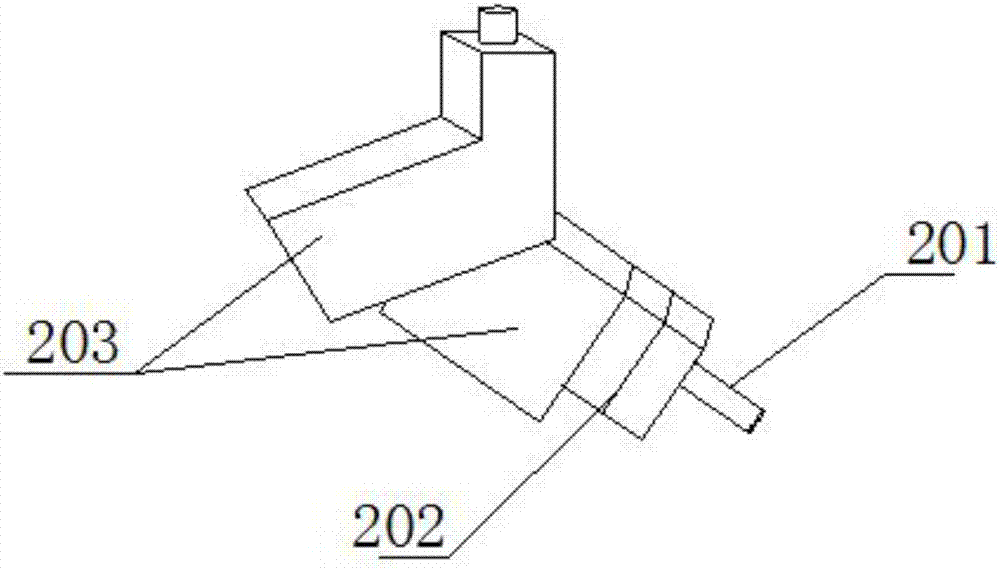

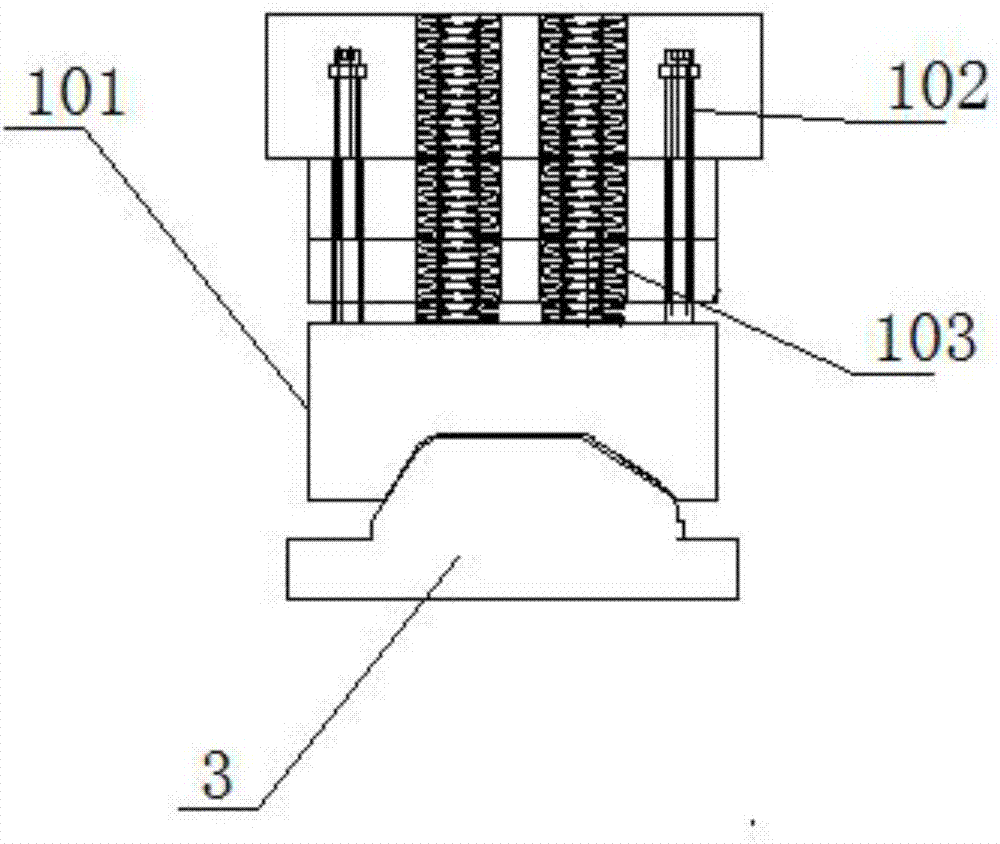

[0014] Refer to the attached drawings: a wedge-shaped piece side-cutting die, characterized in that the wedge-shaped piece side-cutting die includes a self-hanging beveling assembly 2, a fixed taper bottom mold 3, a hanging type taper die 1 and a mold base assembly 4 The mold base assembly 4 includes an upper mold base 401, a guide post 402, a lower mold base 403, a cushion block 404, and a supporting plate 405. The guide post 402 separates the upper mold base 401 from the lower mold base 403 and is self-suspending inclined The cutting assembly 2 is installed at both ends of the upper mold base 401, the fixed tapered bottom mold 3 is installed on the lower mold seat 403, the upper hanging tapered die 1 is installed in the middle of the upper mold seat 401, and the fixed tapered bottom mold 3 is made of Cr12MoV , The Rockwell hardness of the fixed taper bottom mold 3 is not less than 55HRC. Preferably, the self-lifting beveling assembly 2 has four groups, and each group of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com