Automatic discharging machine

A nesting machine and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high maintenance cost, expensive price, complex structure, etc., and achieve the effect of ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

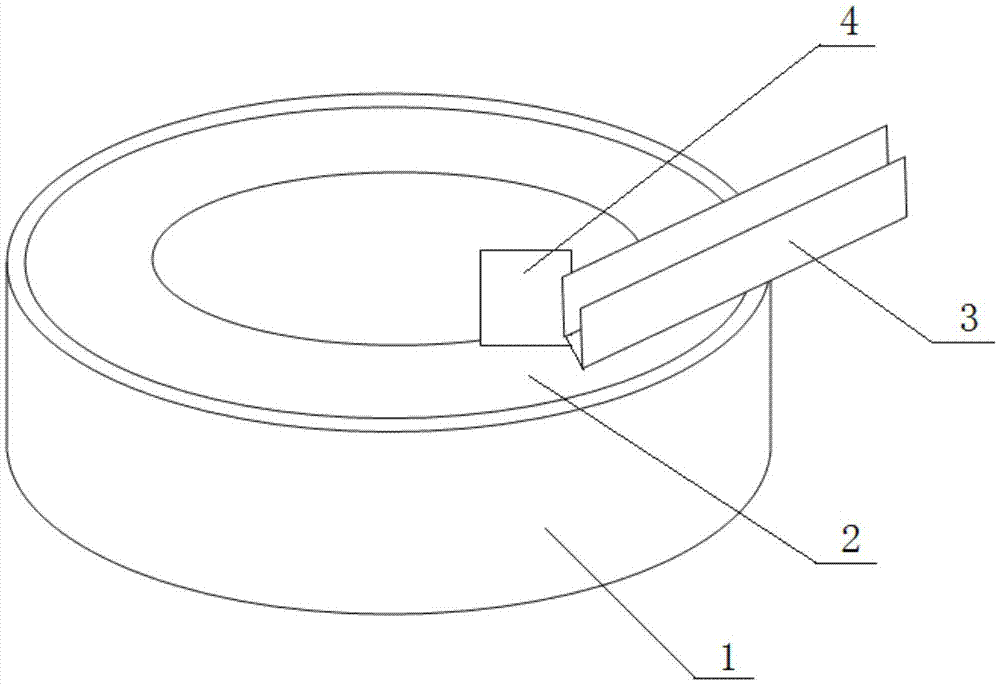

[0014] For further illustrating the present invention, now cooperate with accompanying drawing to elaborate:

[0015] Such as figure 1 As shown, the automatic discharge machine is composed of a circular support 1, an endless conveyor belt 2, a storage slide 3 and a baffle plate 4. An endless conveyor belt is arranged inside the circular support, and the edge of the circular support is higher than the circular conveyor belt. , and set perpendicularly to the endless conveyor belt, the storage slide is placed at an angle of about 30 degrees with the endless conveyor belt, one end of the storage slide is set above the endless conveyor belt and placed close to the endless conveyor belt, and the other end is connected to the feeding device, The baffle is arranged on the outer side of the storage slide near one end of the endless conveyor belt. The storage slide is a rectangular structure with grooves (not shown) inside, so that the material does not shift during the sliding process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com