A kind of industrial waste reinforced and toughened phenolic foam insulation board and its preparation method

A technology of strengthening and toughening and phenolic foam, which is applied to flat products, other household appliances, applications, etc., can solve the problems of failing to meet the application standards of building exterior wall insulation materials and high production costs, and achieve low density, light weight, and high strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

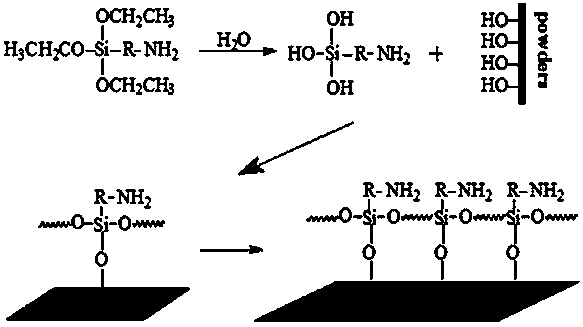

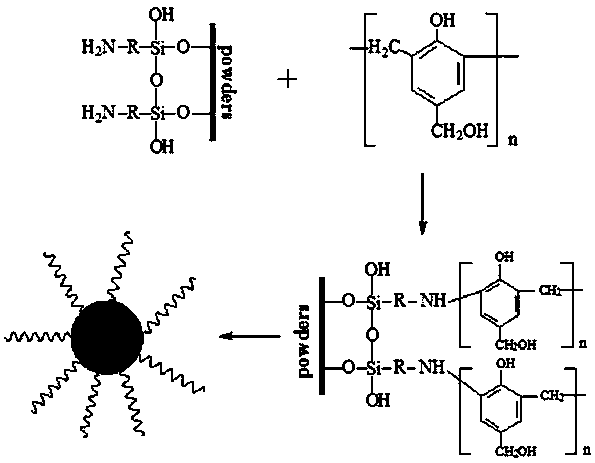

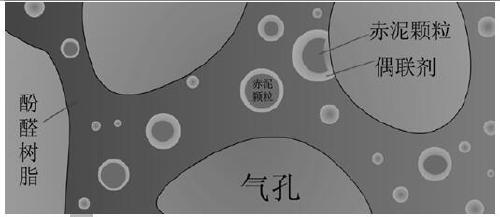

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, add 12 parts of functionalized iron red mud, 3 parts of Tween 60 and 7 parts of n-pentane to 100 parts of phenolic resin, stir at high speed for 5 min at a stirring speed of 1000 r / min, and then add 10 parts of curing agent , continue to stir for 1 min, then pour it into a mold of a certain shape, put the mold into an oven, and pre-cure the phenolic resin at 60 ° C, and remove part of the volatile components and excess solvent at the same time to obtain a prepreg; The obtained prepreg was placed on a molding machine, and kept under a pressure of 0.3 MPa and a temperature of 80°C for 5 minutes to complete the entire foaming process and obtain a functionalized iron red mud reinforced and toughened phenolic foam insulation board.

Embodiment 2

[0031] At room temperature, add 13 parts of functionalized iron red mud, 4 parts of Tween 80 and 7 parts of n-pentane to 100 parts of phenolic resin, stir at high speed for 5 min at a stirring speed of 1000 r / min, and then add 15 parts of curing agent , continue to stir for 1 min, then pour it into a mold of a certain shape, put the mold into an oven, and pre-cure the phenolic resin at 50 ° C, and remove part of the volatile components and excess solvent at the same time to obtain a prepreg; The obtained prepreg was placed on a molding machine, and kept under a pressure of 0.3 MPa and a temperature of 70°C for 5 minutes to complete the entire foaming process and obtain a functionalized iron red mud reinforced toughened phenolic foam insulation board.

Embodiment 3

[0033] At room temperature, add 14 parts of functionalized iron red mud, 5 parts of Tween 80 and 8 parts of isopentane to 100 parts of phenolic resin, stir at high speed for 5 min at a stirring speed of 1000 r / min, and then add 18 parts of curing agent , continue to stir for 1min and then pour it into a mold of a certain shape; put the mold into an oven, pre-cure the phenolic resin at 50°C, and remove part of the volatile components and excess solvent at the same time to obtain a prepreg; Put the prepreg into the molding machine, and keep it under the pressure of 0.3 MPa and the temperature of 80°C for 5 minutes to complete the whole foaming process, and obtain the functionalized iron red mud reinforced and toughened phenolic foam insulation board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com