Machine fabric cutting cutter head

A cutter head and cloth cutting technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy insertion between serrated blades, large installation space, and carbonization of surface cloth, so as to improve the efficiency of cloth cutting and improve the overall strength , to avoid the effect of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

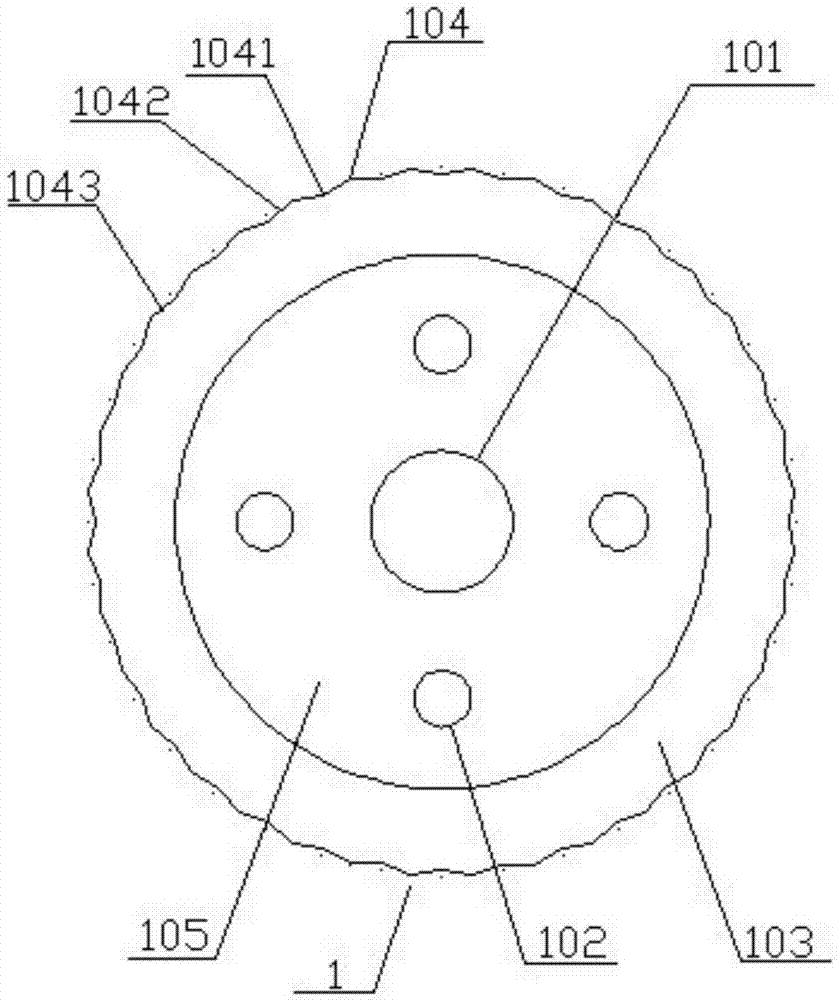

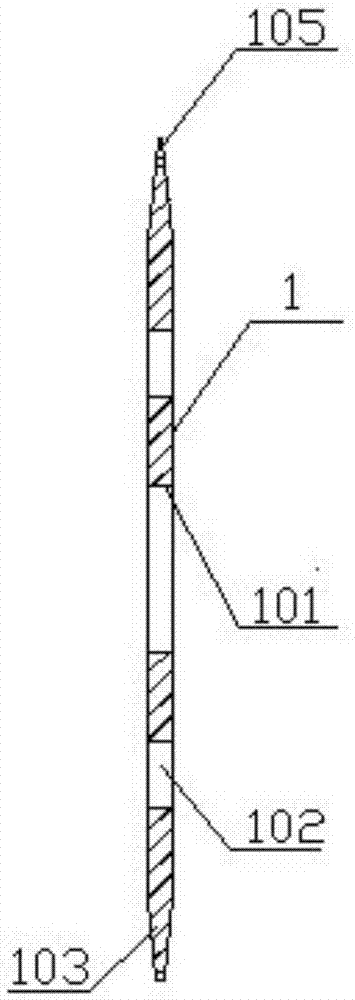

[0013] Such as Figure 1 ~ Figure 2 As shown, the cutter head for machine cloth cutting includes a cutter head 1, the cutter head 1 is a circular sheet, a disc body 105 is arranged in the middle, a mounting hole 101 is arranged in the middle of the disc body 105, bevels 103 are arranged on both sides of the outer side, and The ring is a blade edge 106, four fixing holes 102 are correspondingly arranged on the expansion circumference of the mounting hole 101, the bottom of the hypotenuse 103 is fixed with the disc body 105, and gradually shrinks and becomes thinner, and the blade edge 106 is formed at the top. The blade edge 106 is evenly distributed with several blade tips 104, and a blade valley 1041 is set in the middle of the two adjacent blade tips 104, and the valley bottom of the blade valley 104...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com