Rigid connecting piece steel bridge deck pavement structure and pavement method

A technology for rigid connectors and bridge deck paving, which is used in bridges, bridge parts, bridge construction, etc., and can solve the problem of difficulty in penetrating steel bars for slotted steel plate connectors, poor anti-pulling and peeling resistance of pavement layers, and poor pavement resistance. Layer vertical and horizontal cracking or peeling, etc., to achieve the effect of improving pavement cracking, facilitating mechanized construction, and improving pullout bearing capacity and peeling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

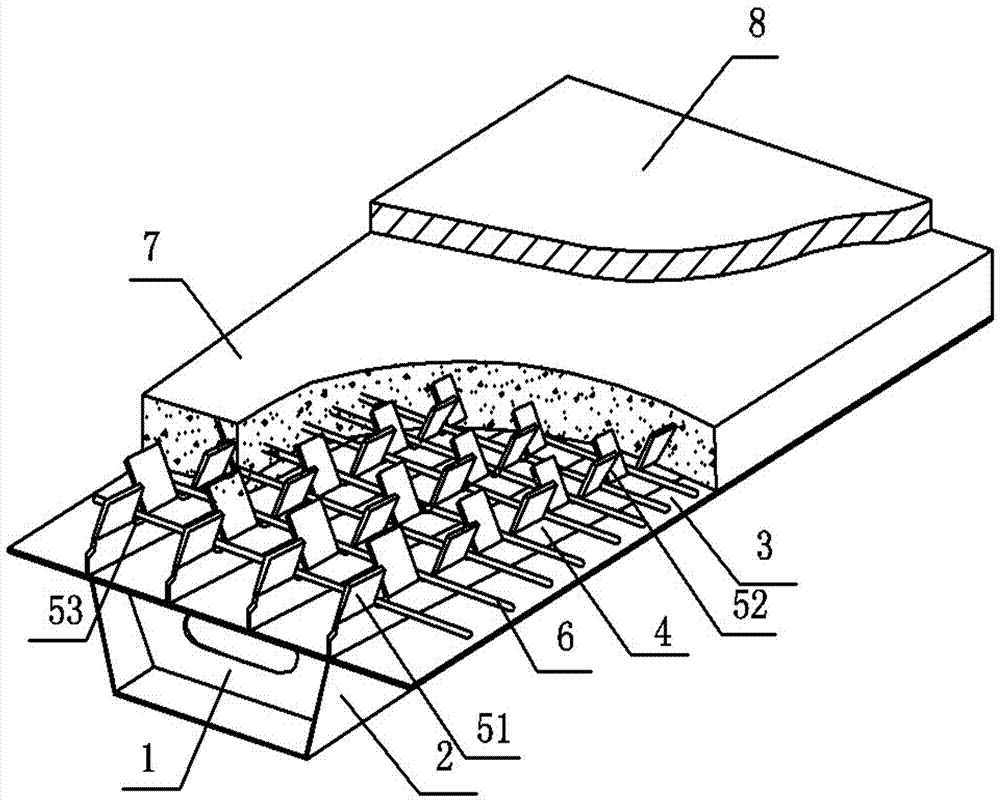

[0025] like figure 1 The steel bridge deck pavement structure with rigid connectors shown includes a roof 3, and a longitudinal web 2 and a transverse diaphragm 1 are connected to the bottom surface of the roof 3. The longitudinal web 2 and the transverse diaphragm 1 are connected to the bottom surface of the roof 3. Orthogonally connected, and the longitudinal web and diaphragm are also connected orthogonally. The top plate 3, the longitudinal web 2 and the transverse diaphragm 1 form a steel beam with high strength and strong compression resistance.

[0026] A bridge deck pavement is laid on the top surface of the top plate 3, wherein the top surface of the top plate 3 is provided with a connector located in the bridge deck pavement.

[0027] The connecting piece includes a steel bar 6 and at least one steel plate 4 vertically placed on the top surface of the top plate 3, wherein the welding between the steel plate 4 and the top plate 3 is single-side welding or double-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com