Novel concrete top die stick

A technology of concrete top and top mold stick, which is applied to the connection parts of formwork/formwork/work frame, structural elements, building components, etc., which can solve the misalignment of top mold stick and cannot control the distance between horizontal ribs and formwork , increasing project costs and other issues, to achieve the effect of stable and reliable structure, convenient binding and fixing, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations rather than limitations of the present invention.

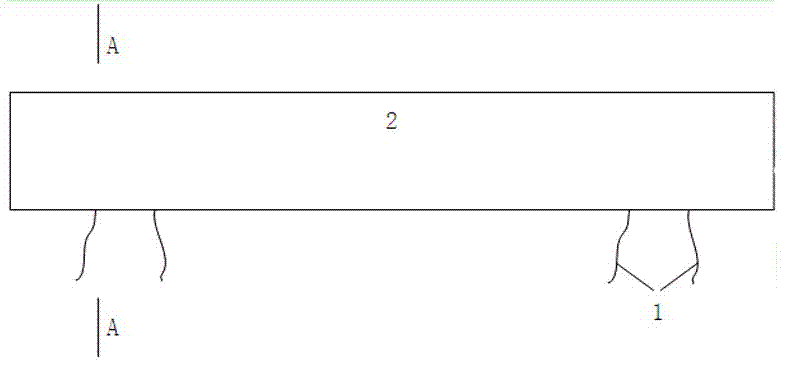

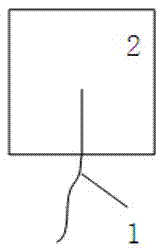

[0015] The invention provides a new type of concrete top mold stick, the overall structure of which is as follows: figure 1 As shown, the cross-sectional view is as figure 2 As shown, it includes a rectangular top mold stick main body 2, two iron wires 1 are pre-embedded symmetrically on both sides of the rectangular top mold stick main body, and the distance between the outermost iron wire and the end of the top mold stick main body on the same side is 1 mm less than the thickness of the concrete protective layer , the distance between 2 iron wires on the same side is 2 ~ 3cm, the length of the iron wire extending outside the main body of the rectangular top mold stick is 6 ~ 8cm, and the diameter of the iron wire is 0.9 ~ 1.6mm; the length of the main body of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com