Method for determining sizes of and distance between artificial pillars for room coal pillar recycling

A technology of artificial ore pillars and room-type coal pillars, applied in mining equipment, earthwork drilling, filling and other directions, can solve problems such as staying in primary ore pillars, and achieve the effect of avoiding accidents, ensuring high efficiency, and ensuring safe production in mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

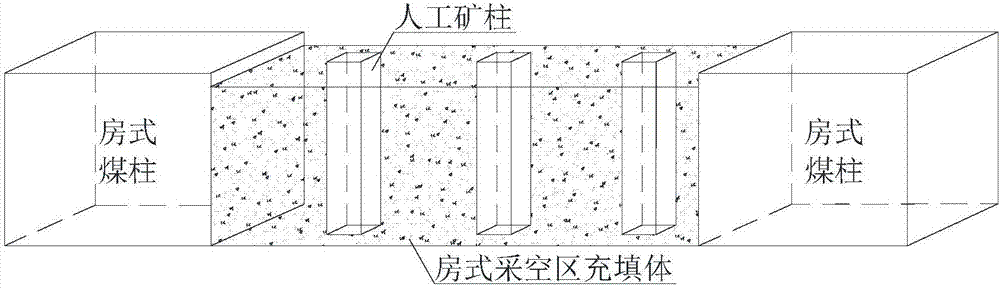

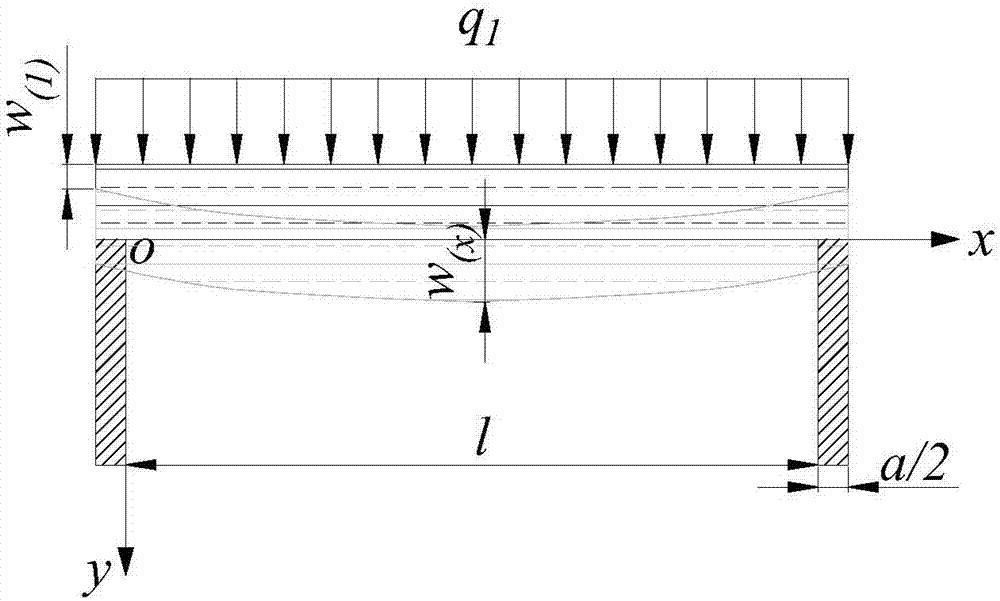

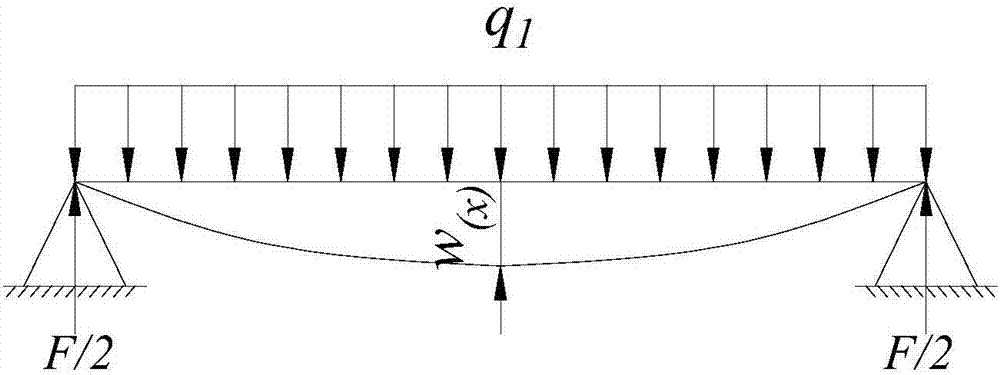

[0041] The method for determining the size and spacing of artificial pillars for recovering room-type coal pillars of the present invention: in the process of recovering room-type coal pillars, the process of supporting the upper roof of the room-type coal pillars is divided into the stage of artificial mine pillars supporting the roof alone Combined support stage with artificial pillars and solid filling materials; according to the force balance principle and the Winkel foundation model, aiming at the support characteristics of the two different stages, the artificial pillars alone support the roof stage and the artificial pillars collaborative solid Based on the mechanical model of the filling material joint support stage, the stress of the artificial pillar is obtained. According to the load on the artificial pillar, it should be less than its allowable stress [σ 1 ], draw the relationship diagram of the artificial pillar size a×a and the artificial pillar spacing l in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com